HP recently announced the release of a new printing system called the 5420W aimed at producing production-grade white parts ready for end use. These new printing capabilities will bring HP Multi Jet Fusion technology to new markets and applications that require consumer-grade components right off the machine. We have the latest scoop on this exciting new development.

Overview of the HP 5420W

HP Multi Jet Fusion technology has been a staple of the additive manufacturing world for a few years now and with the 5420W, HP set out to improve the cosmetic finish of printed parts right off the machine. The traditional gray color that Multi Jet Fusion 3D printers typically produce is not adequate for many end-use products from a cosmetic perspective. To bring these gray parts up to par, post-processing techniques, such as painting or dyeing, are often required before a part can be sold directly to the consumer.

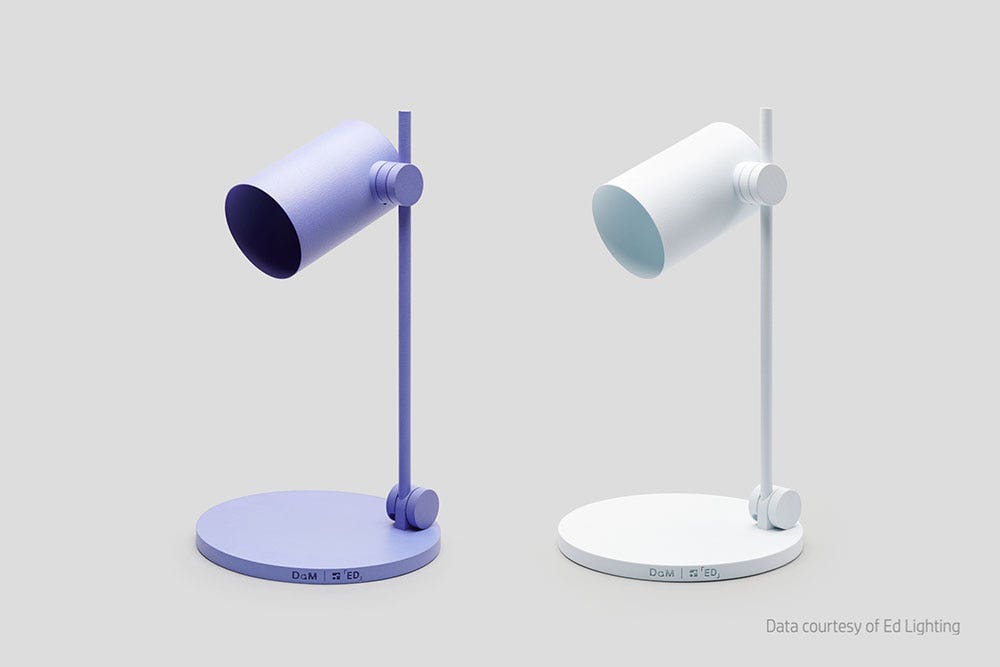

While post-processing techniques can provide incredible results, many customers prefer to skip this step altogether. Parts produced with the HP 5420W are ready for end-use applications to be sold without further post-processing, showcasing a nice white color.

How is the 5420W Different Than Other 5200 Series Printers?

The overall exterior look of the 5420W is identical to the 5200 lineup of printing systems with some small but important changes. First and foremost, the print system will be dedicated to white parts only,

This includes the printer, post-processing station, and build units. This means that the system will no longer be capable of printing gray parts.

The materials and consumables will also be slightly different in this system. The only material that will be available starting out is PA12W, which is like the previous PA12 with an addition of titanium dioxide to add the white color. PA12W will be sold in 300L packages of powder in the same way as before. Fusing agent and printhead design have also changed in this system.

Print times are also slightly longer at 13h 25m for a full build, as opposed to 11h 45m found with the balanced print mode on the standard 5200.

Installation for a new 5420W system takes one additional day for a total of 4-6 days, compared to a 5200 system which typically takes three to five days.

From a facilities perspective, the 5420W will require an extra 1.3ft of clearance on the right side of the machine for maintenance-related tasks. There are going to be a few small maintenance items added to daily, weekly, and monthly schedules although the early feedback we are receiving is that these tasks are minor.

Advantages of the 5420W Color and Material

One advantage of printing with white parts as opposed to gray or black is that white parts are easier to coat with brighter colors. Dyeing of parts is one of the most common industry practices for Multi Jet Fusion and up until now, it was not possible to dye a 5200 series part with bright colors due to the darker base material color. Now parts can be dyed a variety of colors effectively when printed on the 5420W. Postprocessing techniques such as vapor smoothing are also effective with PA12W parts.

White parts produced on the 5420W have also passed tests for several Biocompatibility specifications including:

- Cytotoxicity

- Sensitization

- Irritation/Intracutaneous

- Acute Systemic Toxicity

- Pyrogenicity

Sterilization has also been successful with 5420W up to 132C undergoing multiple cycles at times ranging up to 30min. Observed mechanical properties and dimensional changes were minimal between autoclave, gamma, and e-beam sterilization methods. One major advantage is that the parts going through these sterilizations came out with little to no change in the look and feel.

HP also conducted a specialized weathering test by placing parts under sunlight for extended periods of time (up to 800hrs). In this test, color was measured at each time interval (200hr increments) and the HP sample remained white while competitive white parts on the market began to yellow in less than 200hrs of exposure while the HP samples stayed white through 800hrs of testing. This ability of HP white parts to resist change under sunlight is a major advantage when considering using these components right off the machine to be sold into the market.

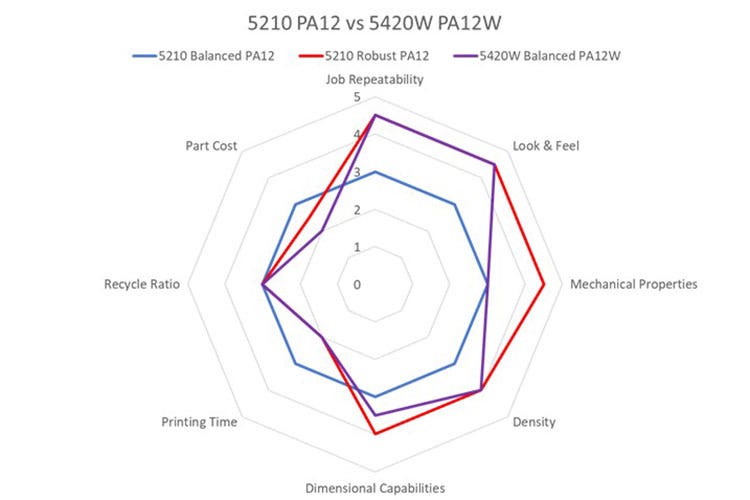

Other comparisons worthy of note are how 5420W PA12W parts compare to 5200 series PA12 parts across different print modes. The 5420W balanced print mode performs close to the 5200 series PA12 robust print mode in almost all aspects. The white-balanced mode draws heavily on the robust print mode from the 5200 series, which came out in late 2022. Check out our blog, “Introducing the Robust PA12 Print Mode for HP 5200 3D Printers,” to learn more.

Long story short is that the 5420W PA12W balanced print mode is better than the 5200 series PA12 balanced print mode (the most popular 5200 series print mode) and almost as good as the 5200 series PA12 robust print mode in key metrics such as look and feel, mechanical properties, dimensional accuracy, density, print time, and powder recycle ratio. If speed and part cost are most important, PA12 balanced or PA12 Fast mode (not shown on the chart) are still going to be the best choices.

What are the Ideal Use Cases for the 5420W?

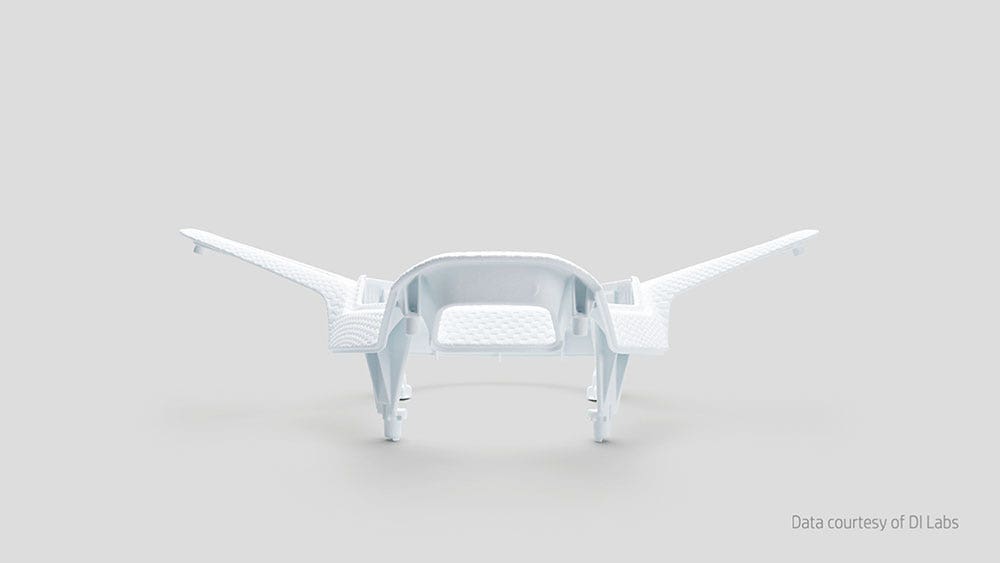

Ideal use cases for 5420W are for those customers that would like to produce parts that are ready to be sold to the market right off the machine without the need for additional finishing. A second use case is where the intended final color needs to be very bright through painting or dyeing. These types of applications will benefit from starting with a white base. Industries that currently use heavily white components also would be good fits such as medical industries or consumer goods.

Part Cost Considerations

From a part cost perspective, HP Multi Jet Fusion white parts will be more expensive than gray parts when comparing the 5210 platform to the 5420W platform. Both powder and fusing agent are more expensive on the 5420W compared to a 5210 printer. Detailing agent, printheads, and cleaning rolls will be the same price between units. From our calculations, we are estimating about a 17 percent increase in cost per part in this scenario. However, when comparing the 5420W to a standard 5200, the 5420W will have a slightly cheaper part cost since the powder is still cheaper despite the fusing agent being more expensive. The 5420W produces parts about 15 percent cheaper than a 5200, from our calculations.

5420W parts can be billed at more of a premium since they can often be used with no additional post-processing or special finishing techniques. This will ultimately save time and money on the back end making it a desirable option for many use cases.

Can an Existing 5200 be Upgraded to 5420W?

If you already have a 5200 printer in your fleet and would like to upgrade, you are in luck! HP plans on releasing upgrade kits for both 5200s and 5210s around May of 2023. The upgrade kit is not available for 5210PROs at this stage. Existing 5200 printers must first be upgraded to 5210 before making the upgrade to 5420W.

How do Parts of the 5420W Compare to Parts from the Previous 500 Series of Printers?

Parts from the 5420W have a completely white core as opposed to the 500 series of printers that printed only a thin white outer shell. Also, the color consistency part to part has been evaluated to be much higher with the 5420W making it ideal for production volumes of components. The 5420W is built upon the production 5200 platform which has greatly increased reliability and accuracy compared to the 500 series of machines.

There you have it; we have reviewed the exciting new 5420W printing system from HP. Printing production quantities of white end-use parts is now easier than ever. For pricing and more info feel free to contact us at Hawk Ridge Systems today!