AMT Vapor Smoothing Systems

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

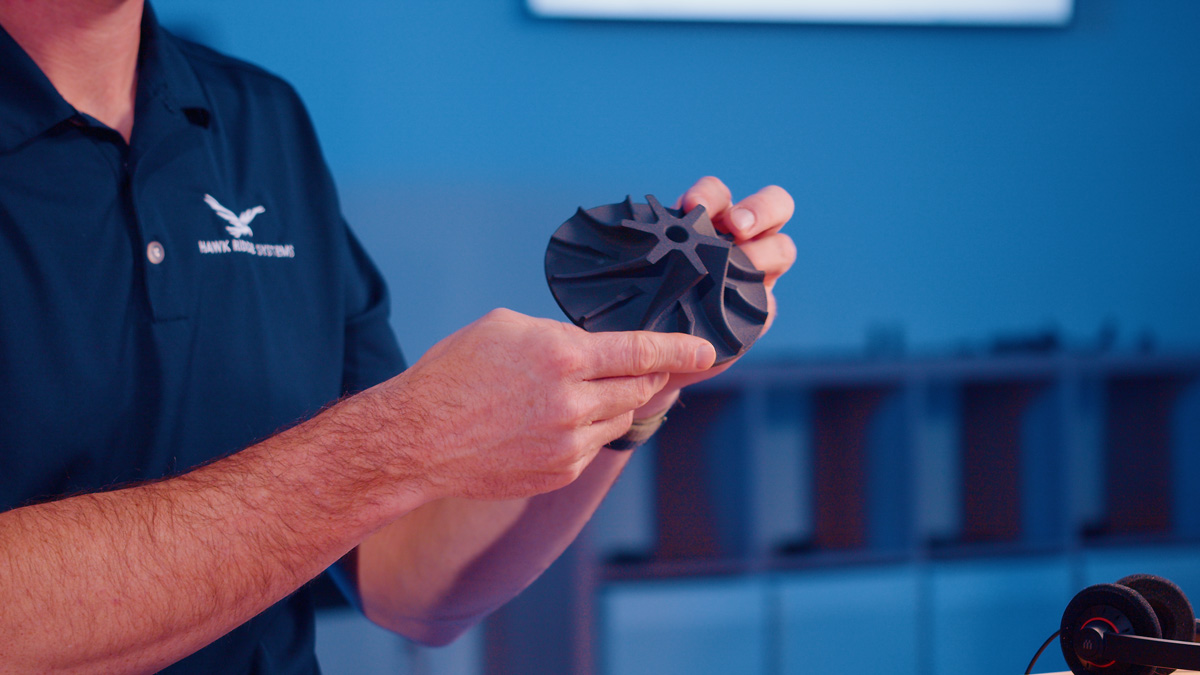

Vapor Smoothing Post-Processing for Beautiful 3D Printing

Smooth your 3D printed parts to injection mold-like finishes using the AMT PostPro SF100 and SF50. These post-processing systems use a chemical polishing process that gives your parts a beautiful look while also improving color uniformity and, in many cases, sealing against water. These vapor smoothing machines can process parts from many different additive technologies, including:

- Selective laser sintering (SLS)

- Fused deposition modeling (FDM)

Technical Specifications

|

Features

|

PostPro SF100

|

PostPro SF50

|

|---|---|---|

|

Chamber Dimensions

|

15.7” x 23.6” x 15.7” (400mm x 600mm x 400mm)

|

15.7” x 11.8” x 15.7” (400mm x 300mm x 400mm)

|

|

Process Chamber Volume

|

96 Liters

|

48 Liters

|

|

Machine Dimensions

|

33” x 55.5” x 72” (830mm x 1400mm x 1830mm)

|

33” x 55.5” x 72” (830mm x 1400mm x 1830mm)

|

|

Power Requirements

|

400V 3-Phase 16A

|

220-240V 1-Phase 16A or 400V 3-Phase 16A

|

|

Machine Weight

|

1,875 lbs.

|

1,765 lbs.

|

|

Recommended Operating Area

|

92.5” x 126” (2350mm x 3200mm)

|

92.5” x 126” (2,350mm x 3200mm)

|

Transform Your 3D Prints with AMT PostPro Vapor Smoothing

Are you looking to elevate the finish of your 3D prints to a professional level? Look no further than AMT’s cutting-edge PostPro vapor smoothing solutions.

Our innovative technology seamlessly smooths layer lines, eliminating the need for extensive post-processing. With AMT PostPro, achieve flawless surfaces, improved mechanical properties, and a premium finish, all in a cost-effective and efficient manner. Say goodbye to rough edges and hello to unparalleled quality.

Post Processing Resources

Give Your Printed Part the Finished Look It Deserves

Watch Webinar

Design, Print, Ride – A Product Journey

Watch Webinar

3D Printer Buyer’s Guide

Download GuideFrequently Asked Questions

Yes, the equipment requires proper ventilation or exhaust systems in your facility.

The used chemical is extracted into canisters that are swapped out for new canisters by AMT. The user is not responsible for disposing of the chemical.

If you are running the PostPro SF100, a chiller unit and extractor are required to operate the system. An optional extraction system is recommended for use in addition to the PostPro SF50.

The PostPro SF100 and PostPro SF50 both use a closed-loop system so the user should never come into contact with the vapor smoothing chemical under normal operation.

Cycle times are 1 – 2 hours depending on the level of smoothness desired.

Yes, parts still need to be bead blasted before post-processing in these machines. Any powder that is not blasted can negatively affect the vapor smoothing process.

Services & Customer Benefits

Technical Support

Our dedicated team is here to provide comprehensive support, including thorough pre-installation planning and expert installation services. By leveraging our expertise, we ensure a seamless process to swiftly set up your AMT system, allowing you to get up and running with ease.