Artec3D has become an industry name for people looking to do targetless 3D scans of objects for reverse engineering, quality control, and archiving.

One of their most popular scanner, the Space Spider, changed the game for targetless 3D scanning.

The Artec Spider II aims to take what made the predecessor known and improve upon it by providing higher levels of mesh resolution, a faster scanning experience, and improved lighting and cameras for tracking.

Double the Resolution and Scanning Speed

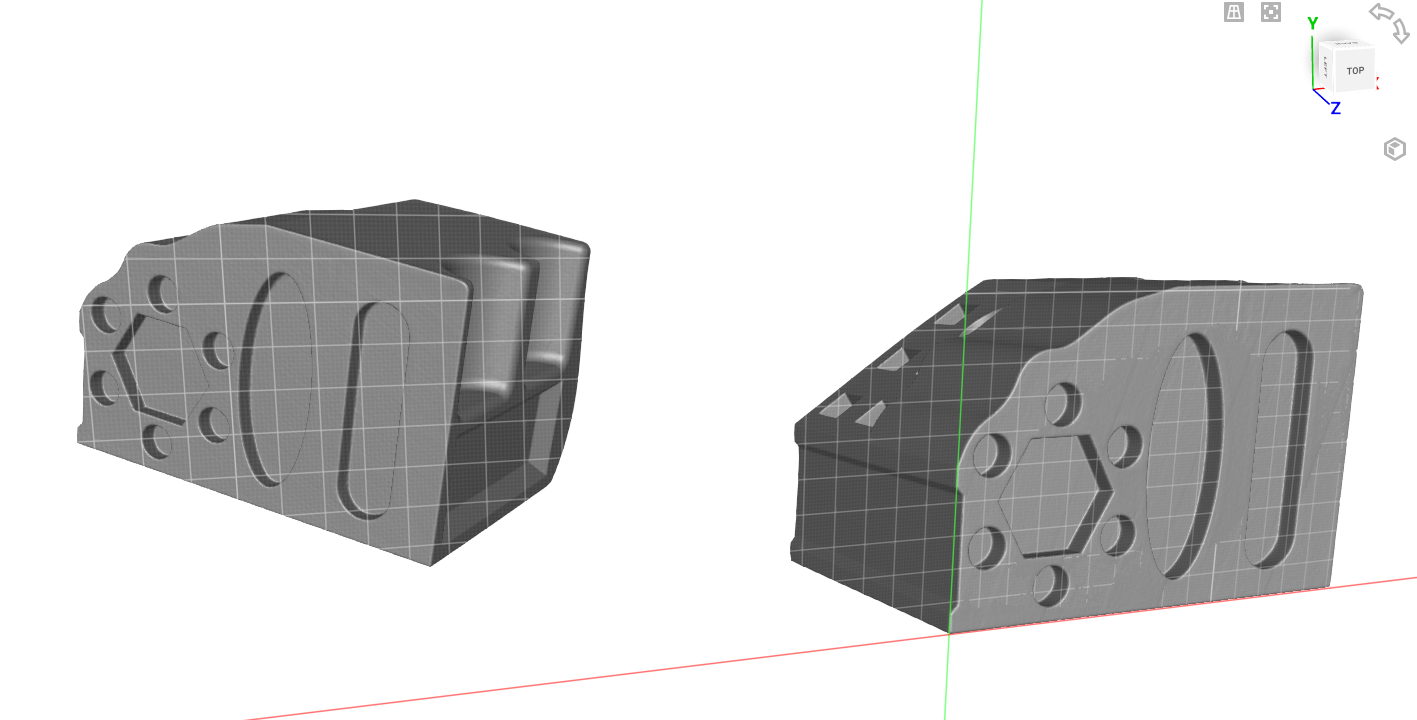

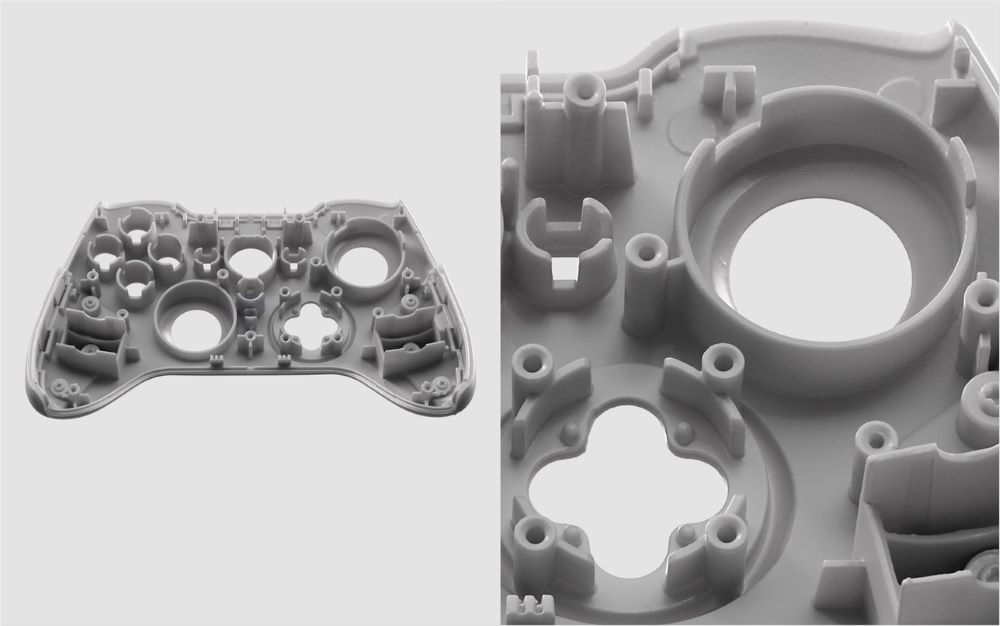

With a whole new hardware system, the Spider II has the ability to scan details of up to 0.05mm resolution. Crisp details of your parts come through in a wide range of applications, like showing the details of a coin to intricate parts of an engine.

Targetless and contactless scanning allow for no loss in capturable surface, keeping the object true to shape for inspection and reverse engineering.

The Spider II also boasts a scanning speed of 15 fps – resulting in faster scanning times as the user can move quicker around the object to scan it. Additional data acquisition from the faster FPS allows operators to have an easier time scanning complex components and maintain tracking through the scanning process.

Blue-Light Technology and Wider Field of View

The Spider II uses blue-light technology to help capture normally difficult surfaces for light-based scanners. Darker and glossy surfaces may require additional preparation or be captured at several angles to produce good results using traditional white-light technology.

Blue light, however, reduces the noise generated from these difficult surfaces and allows for an easier time to capture it – opening up new applications for users with preparation requirements for their parts.

The scanner’s field of view has also been increased – it is now 128 x 104mm at close range and 171 x 152mm at further distances. Not only does this further help the scanner’s ability to track since it allows for more geometry to be captured at once, but also allow for larger object scanning.

The Spider II is suited for scanning of medium-sized objects easily, such as a car engine, whereas the Space Spider would require several scans in multiple positions for a similar object.

Improved Color Quality of Scans

The new hardware of the Spider II also increases the scanner’s color capturing capabilities. A set of 5 MP cameras allows for richer colors to be captured, giving more realism to the scans made.

Or, use Artec Studios photo coloring capabilities to use DSLR photos to further improve the texture of your 3D scans.

Top 3D Scanning Applications

Now that we’ve talked about the incredible features, let’s explore the top applications for using the Artec Spider II.

Reverse Engineering

Scan smaller to medium-sized parts in high-resolution at with sharp edge detail. Perfect for replicating legacy parts and making changes to them or designing around critical components.

Quality Control

With increased details and accuracy, use scan data to create 3D inspection reports and first article inspection. Providing information like color maps for surface quality or hole locations positions.

Digital Archiving

Digitize objects like legacy components, artifacts, consumer products, and accessories to create digital twins for archiving. Making collaboration and documentation easier for different departments.

Prototyping

Quickly scan critical locations of objects to identify design constraints and design around them. Removing the guesswork that comes with designing around components and streamlining design choices.

Education and Science

Show minute details of historical, preserved, or organic shapes that would be difficult to replicate or express without photos for research and education.

Final Thoughts

The Artec Space Spider has been an industrial powerhouse for those looking to create detailed 3D scans of smaller parts. With the Artec Spider II, users can expect improvements in all aspects, from scanning speed to details and quality.

And for those who require contactless and targetless scanning the blue light technology with larger field-of-view increases the range of materials capturable and ease of scanning larger objects.

Opening the scanner to new applications and industries the previous Space Spider could not meet.

Along with using Artec Studio’s new enhanced processing, CAD, and Inspection tools the Spider II fits in perfectly for those looking to extract key information and create heatmaps from their 3D scans all within a single software.

Ready to experience the next generation of 3D scanning? Contact us today to learn more about the Artec Spider II and book a free demo!