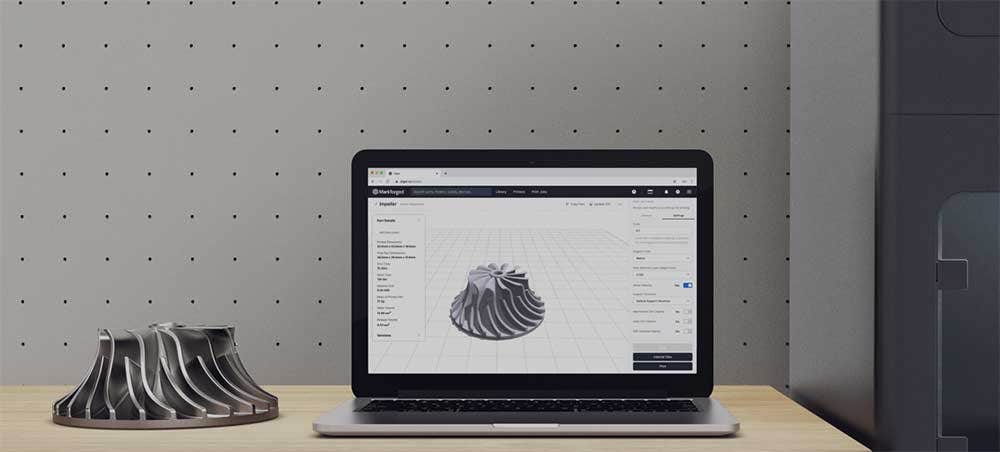

Markforged has just released a robust software called Eiger Fleet, which is a cloud-based software designed to help customers seamlessly scale their printing operations. This software is aimed at organizations that have multiple printers across many users who need to add high throughput workflows, business integration and custom analytics to their workflow. In this post, we’ll provide the scoop on Eiger Fleet.

Eiger Fleet Features

In addition to the great features already found in Eiger Core that the majority of Markforged users are working with, Eiger Fleet has the following add-ons:

• User and Device Management

• Business Process Integration

• High Throughput Workflows

• Custom Analytics

User and Device Management

Eiger Fleet allows for centralized creation, control, and oversight of user teams, device groups, folders, and analytics related to part cost, and lead time tracking. One way this is accomplished is through Role-Based Access Control (RBAC). This functionality allows organizations to control which parts, builds, devices, and print operations are accessible to users based on job responsibilities and titles. This capability can also prevent users from making unauthorized changes to print settings or user permissions.

Business Process Integration

Through Eiger API, businesses can integrate additive management into existing enterprise systems such as CRM, ERP, PLM, MES, AMS, and many more. Single corporate sign-on (SSO) is also now available which will enable users to have consistent sign-on details across many integrated systems. SSO is a great tool for IT administrators to add and remove users from multiple accounts at the same time. Eiger fleet also allows non-technical individuals to select and send a pre-defined part to the nearest printer with a click of a button. A great example of this feature would be when a technician needs to produce a spare part from the company’s digital inventory. With business integration, they could make the part that is needed without needing in-depth knowledge of additive manufacturing. This ability can then be utilized on a global scale across many facilities and hundreds of users, allowing organizations to truly control their supply chain.

High Throughput Workflows

The ability to manage large amounts of digital inventory is now much easier by the use of features like batch operations, organization-wide part setting presets, and automated QA reporting through Blacksmith.

Custom Analytics

Tracking and analyzing your print data across a large pool of printers and users can be effectively viewed and shared. Through custom fields, key performance indicators can be identified and tracked to improve processes, reduce print time and part costs. This data can then be used to understand and monitor ROI or savings gained over time.

Is Eiger Fleet Right for Me?

In summary, here are key indicators if Eiger Fleet may be right for your organization:

- You have multiple printers/users/facilities

- Your organization has already adopted additive manufacturing and want to scale

- You need additive manufacturing to be integrated with existing business practices

- You have IT professionals in your organization that can link your AM process with existing business enterprise solutions through Eiger API

- You need to streamline your additive analytics to help you make business decisions

- You are looking to increase efficiency in your additive workflow as you scale

Eiger Fleet is available on all Markforged printing systems and will be offered as a subscription service.

There you have it, be sure to keep an eye out for future blog posts regarding Eiger Fleet as updates become available. If you would like to explore Markforged Eiger Fleet for your organization, feel free to contact us at Hawk Ridge Systems today!