Validate your design results with SOLIDWORKS Simulation

In part two of this three-part Simulation series, Product Manager Silvio Perez shows how the results obtained from SOLIDWORKS Flow Simulation can accurately predict stress and fatigue, optimizing the equipment for factors of safety and product life. From the first concept to the final prototype, SOLIDWORKS Simulation enables engineers to predict the impact of stress, heat, vibration, and much more to analyze and correctly predict a real-world failure.

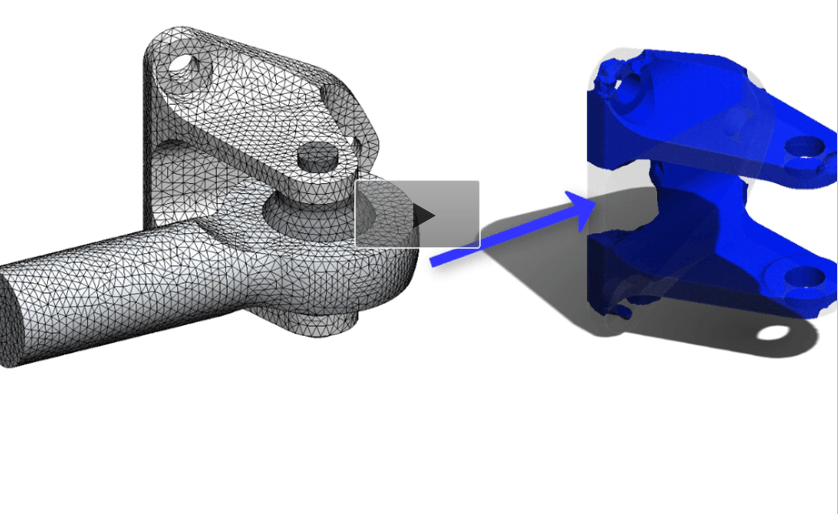

SOLIDWORKS Simulation helps users validate their product performance and safety factors with Finite Element Analysis (FEA) to perform a structural simulation to optimize your components, parts, and assemblies. Hawk Ridge Systems simulation experts can help you bring your designs to reality so you can bring your products to market faster. Get Started Today!