The idea of a single software ecosystem makes a lot of sense. Everything is designed to work together – a familiar, consistent UI across all applications, compatibility, simplified system administration and maintenance and so on. The applications are developed by the same people, using a common design philosophy and product knowledge. A common platform allows an organization and its users to get trained faster, work more efficiently, enhance organizational visibility, reduce or eliminate manual data entry, mitigate errors and deliver a better overall result.

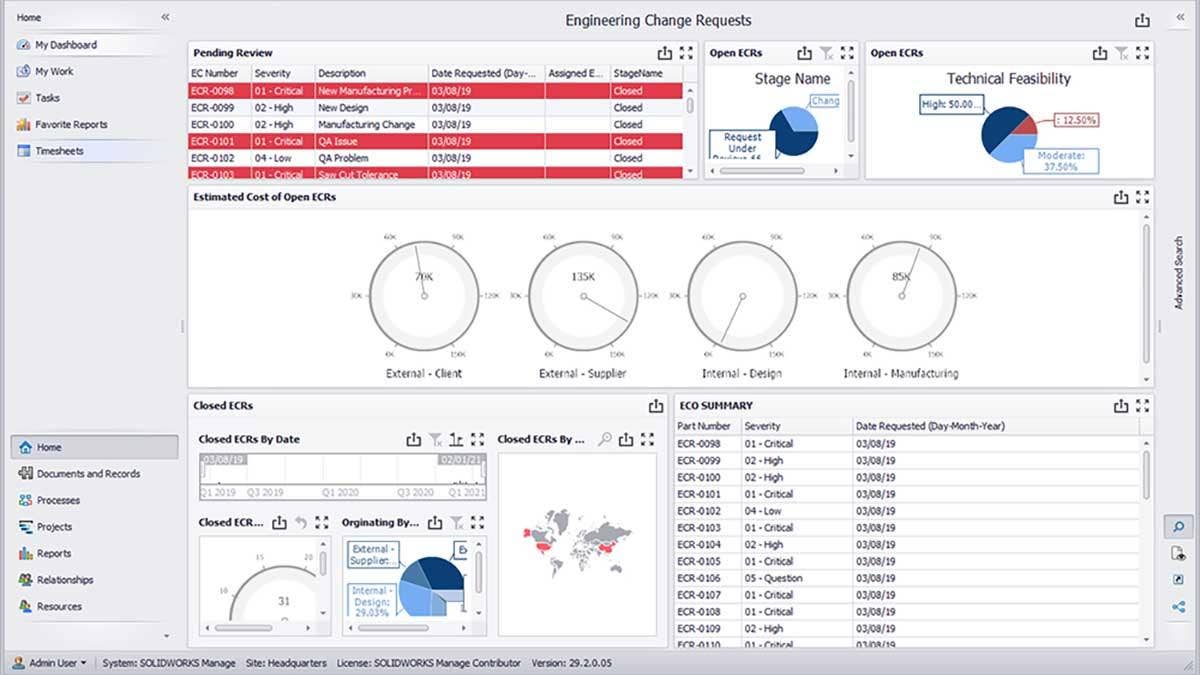

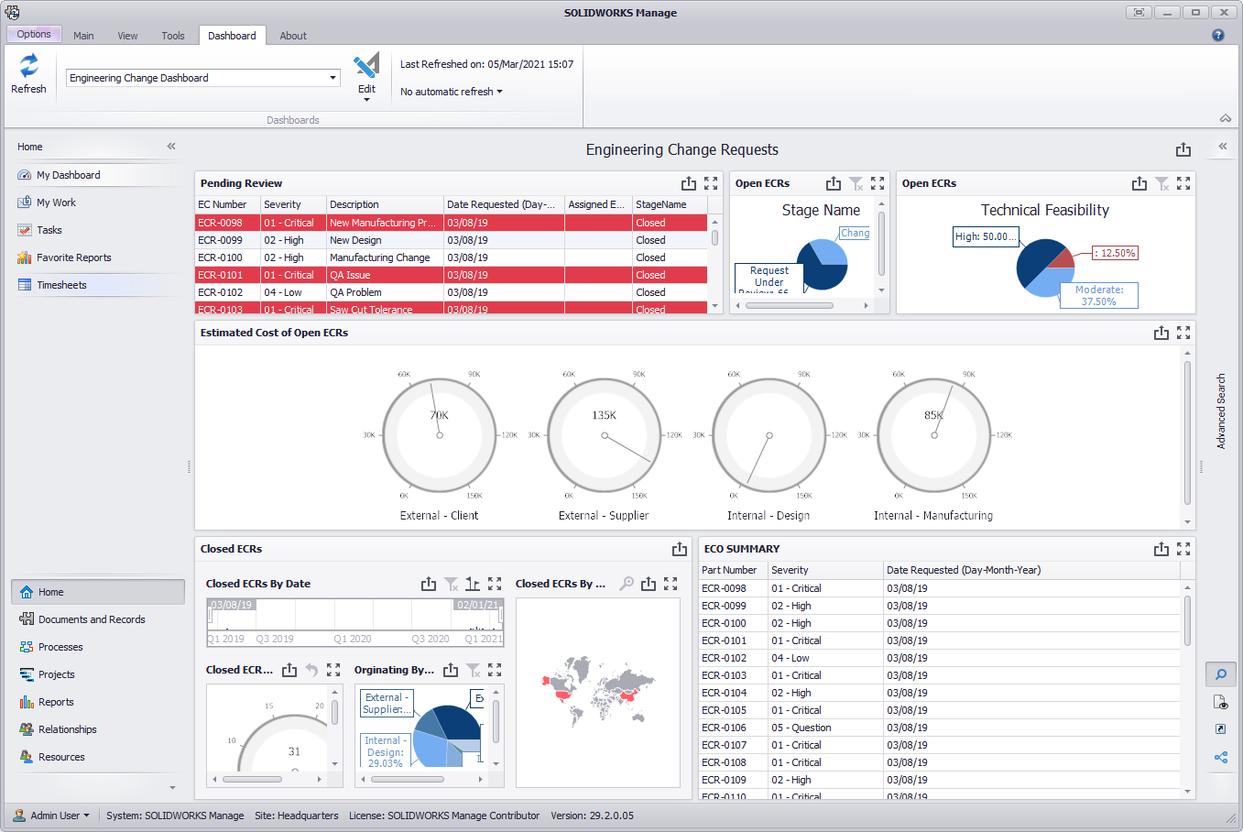

Business analytics across multiple disciplines and departments – a benefit of consolidated systems.

All too often, we find ourselves not well positioned to take advantage of this. Whether it’s adopting different systems over time without the benefit of foresight, inheriting applications through acquisitions, or simply being unable or unwilling to disrupt the status quo, there are many reasons we find ourselves working in many disparate applications, struggling to keep each one up to date with the others.

The Problems With Manual Data Entry

I’ve helped a lot of customers with their data management challenges over the years, and a consistent theme is that they have several applications or processes in place to do various things, and usually there’s a bunch of manual data entry along the way. Is anyone still building BOMs in an Excel document? You bet.

There are many problems with this, as you can imagine. Mismatched and outdated information between systems and departments, inefficient use of engineering time, a lack of visibility and metrics for project activity, siloed application or process knowledge, and so forth. Band-aid solutions to deal with non-integrated systems are not a good long-term strategy, and often there is specialized knowledge only a few people in the organization have to maintain such a system of connected information.

The extra time and risk associated with manual data entry gets repeated every time something changes in an upstream process.

As manual data entry is a common problem across most industries, there’s a huge amount of content already out there to read, and myriad examples that show just how much damage manual data entry can cause in terms of time and cost. So, we don’t need to dive deeper into it here.

A System Consolidation Scenario

Let’s get back to the broader benefits of system consolidation. Here is a typical scenario that captures a lot of the challenges of running disparate applications to manage your data:

ACME Corp has been in business for many years, and over that period many software applications were implemented. Often the applications chosen were the right (best) fit at that time, or available at the right price. Over time, ACME invested a lot of time and money into these applications, and they have a tremendous amount of data in them. Companies and technology advance at a fast pace, however, and ACME was prudent to start planning for inevitable change.

A group of ACME department heads meet to discuss their requirements for a new PDM/PLM system. During the meeting, it becomes apparent that some departments know little about how other departments operate, and some individuals have a completely different understanding of how things work. This meeting also highlights that there are processes in place throughout departments that are still entirely manual (hello, Excel!). These processes are disconnected from any source data and rely on significant manual effort to create and maintain important things like design documentation, BOMs, project reports and other outputs from project and design data.

There are many reasons why ACME finds itself here. Some of their applications were implemented years ago, and over time more software was added to meet new requirements. In some cases, a more modern application became a better fit, and it was implemented for some, but not all departments. The cost of updating or eliminating legacy systems often seems too high, but it’s also important to look at the cost of not making a change, right?

ACME had come to a point where there were too many applications to maintain (from a pure cost AND administration standpoint) and train users on, and they were held together by manual processes that were prone to costly mistakes.

The solution for ACME was to consolidate many of these systems into a modern PDM/PLM application that provided the same capabilities, but in a single platform – SOLIDWORKS Manage.

SOLIDWORKS Manage Benefits

Let’s take a look at some of the benefits of system consolidation. SOLIDWORKS Manage is a great solution for this, as it offers many advanced PLM features with tight integration to your SOLIDWORKS PDM Pro vault.

SOLIDWORKS Manage brings together some key capabilities that you may find beneficial:

- BOM and item management

- Process management

- Project and task management

- And, to ensure everyone has visibility to the above items, dashboards and reporting tools

All four of these feature sets offer value in terms of consolidating your applications but I’d like to focus on three of them.

Process Management

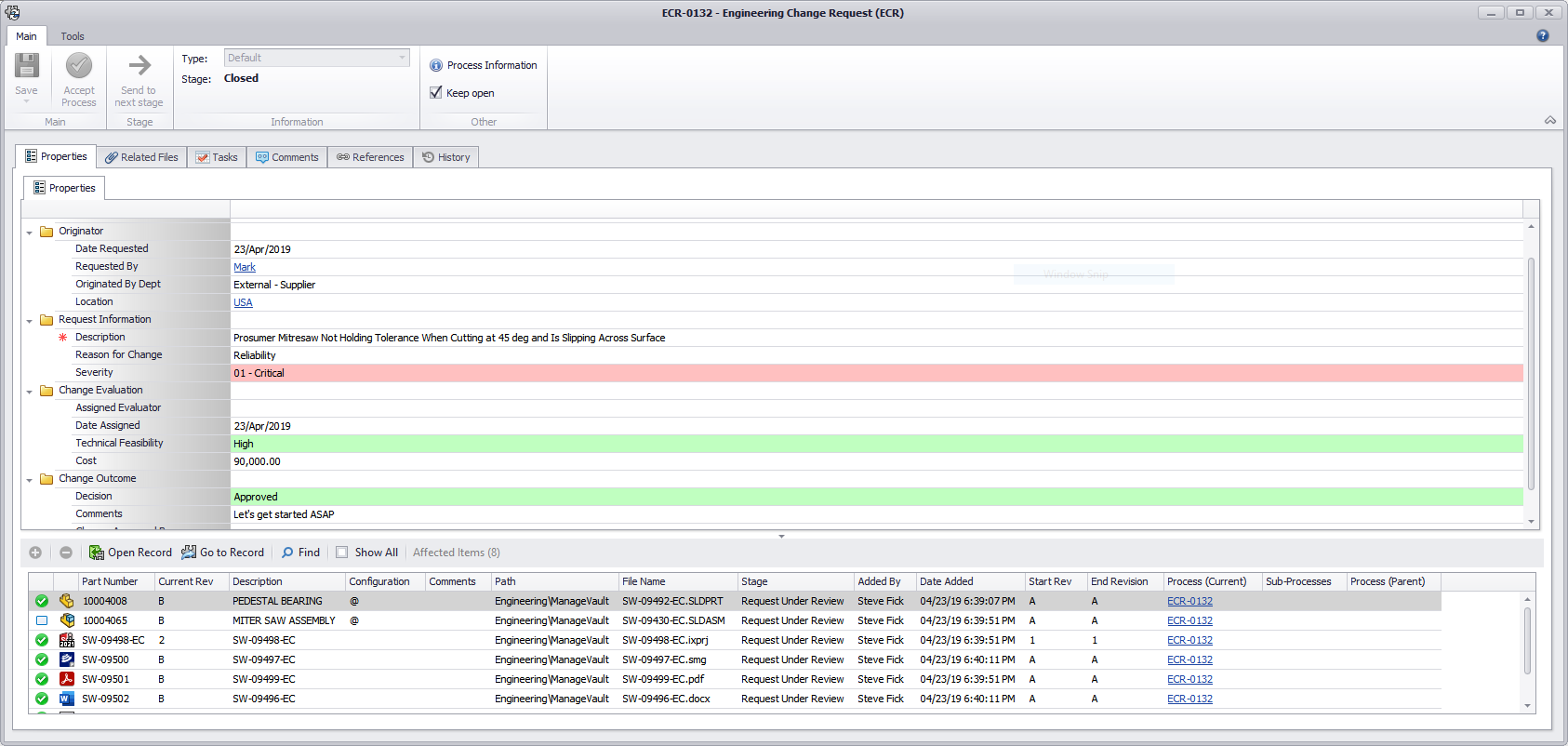

SOLIDWORKS Manage processes, such as an Engineering Change Request (ECR), offer advanced features to meet the challenges of your organization. Integration with various systems is possible, such as requesting an ECR directly from Microsoft Outlook, which will trigger the creation of the ECR within Manage and attach the email plus any reference files that were part of that email request. This is a very cool feature that helps retain all the information from the original request.

In the example above, I’m able to attach all related documents and records tied to this ECR, ensuring everyone involved has access to the right information. You’ll notice this also gives me the ability to assign tasks to my change management team, something that ties in nicely with the next capability.

Integrated Project and Task Management

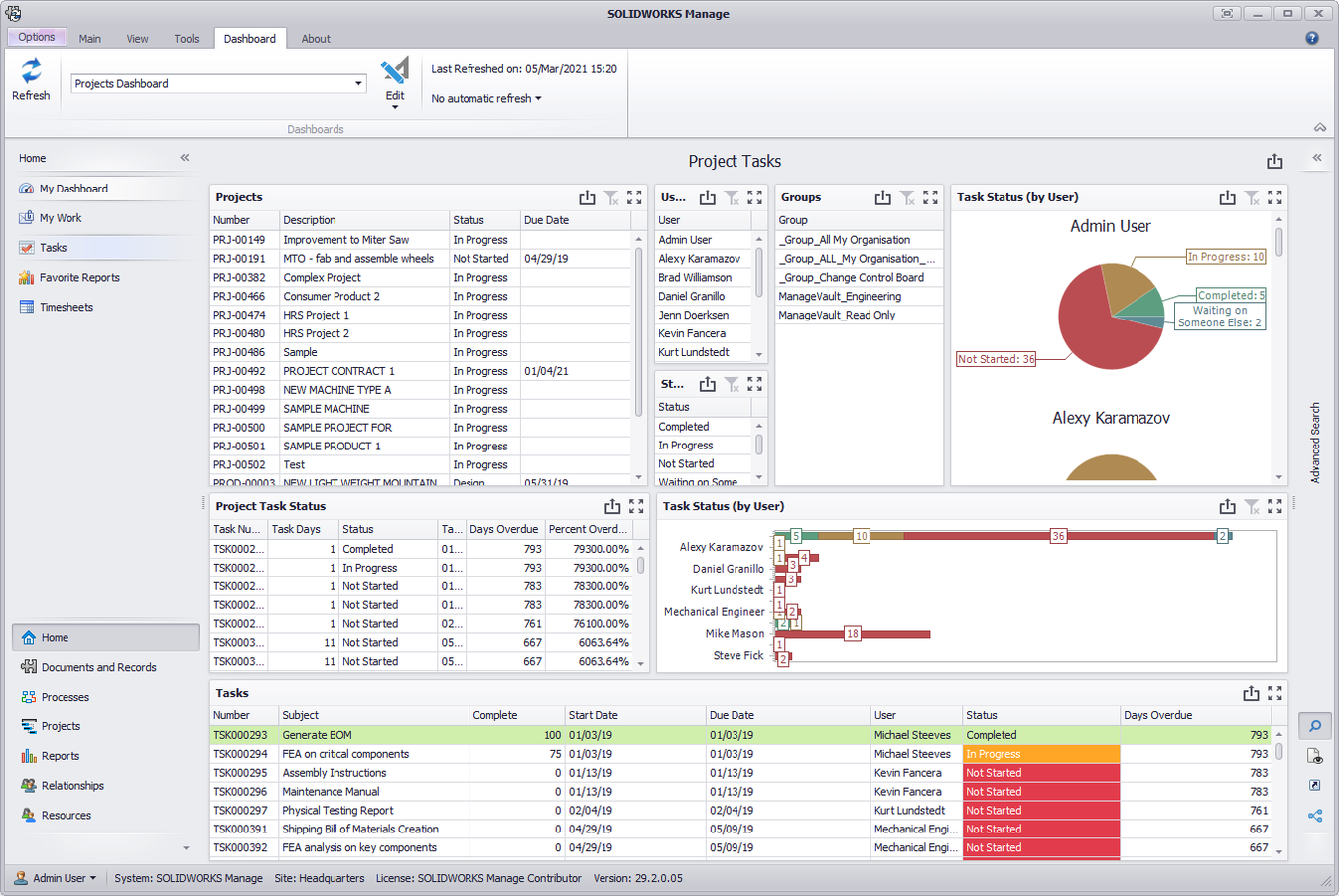

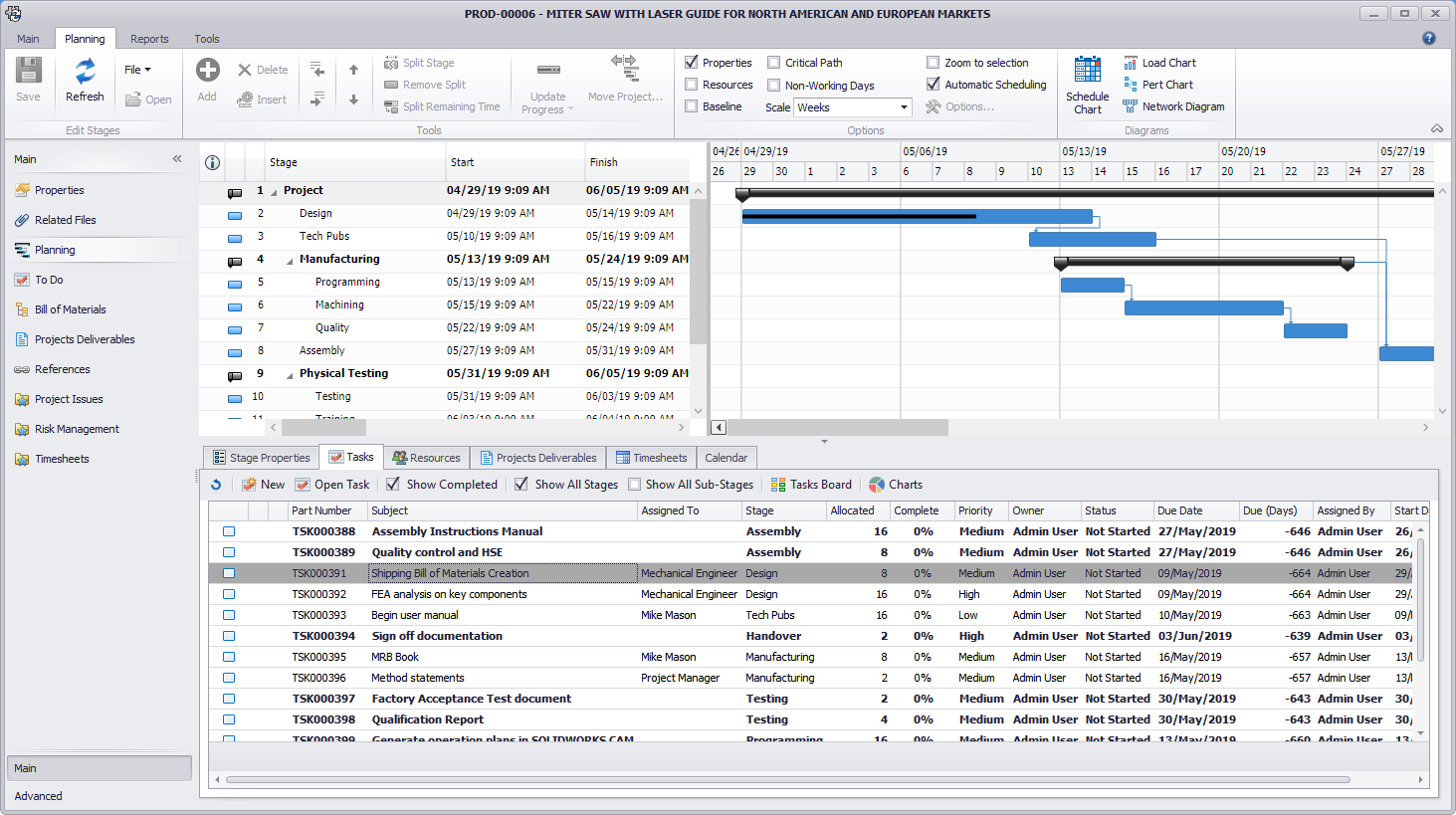

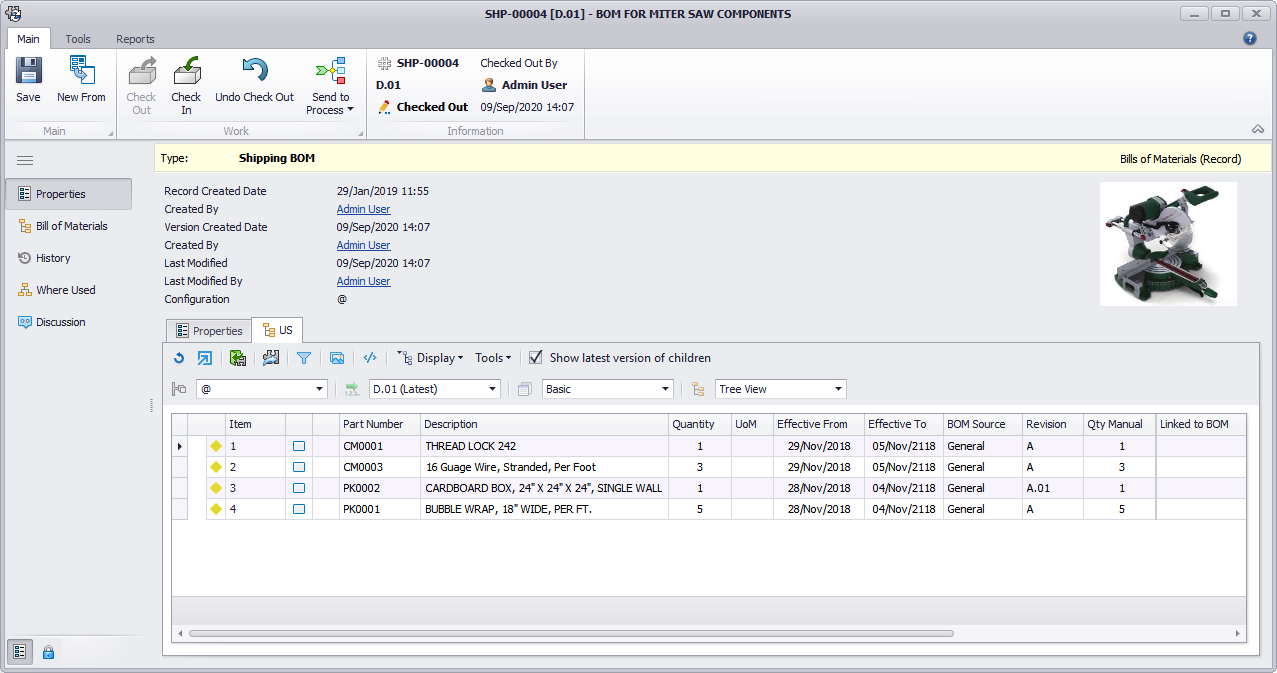

SOLIDWORKS Manage gives you the ability to directly link critical data, such as CAD models, BOMs and reference documents to your project stages and their associated tasks. Given that all this critical data can reside in the same system, the links are to live documents, so any changes upstream will be reflected within the project. For example, if there is a task to generate a BOM, the BOM record can be created, populated, and approved from within SOLIDWORKS Manage. The project record is kept up to date with all task progress so the project manager can remain informed and see the latest changes to that BOM.

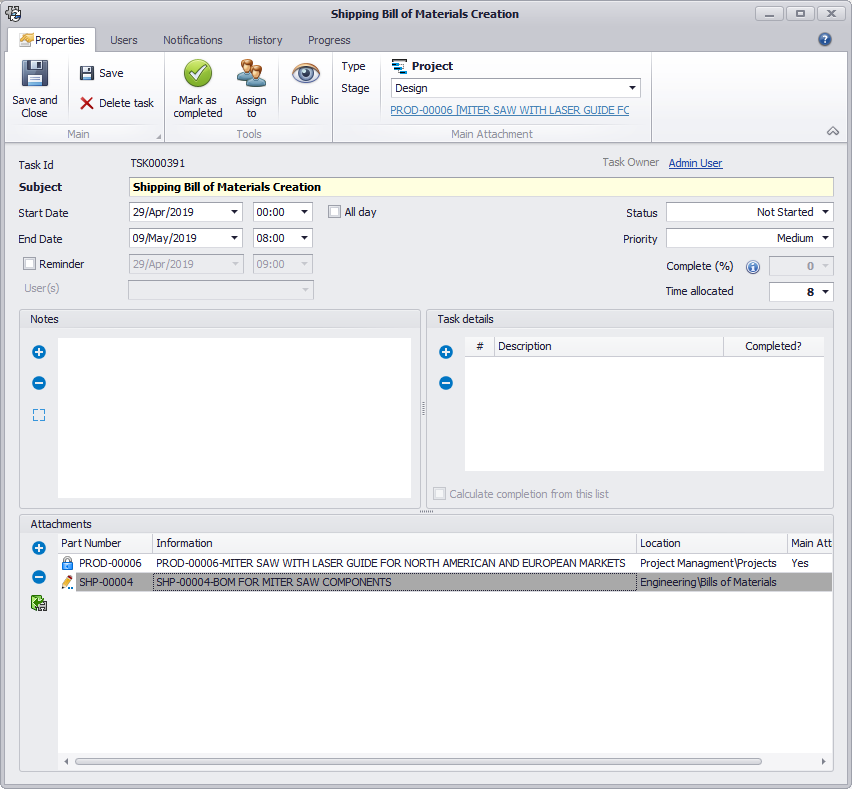

In the example below, I can see that I’ve been assigned a task to create a BOM within my project.

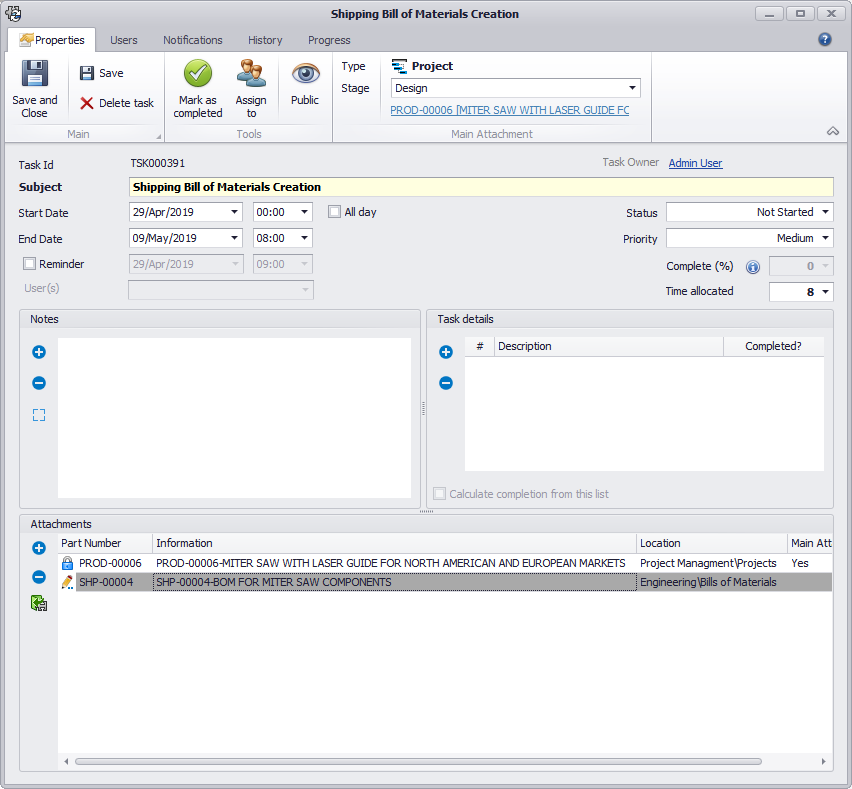

From the task list, I’m able to directly navigate to the task details, as well as the related documents for the task. In my case, this includes the parent project details and the BOM that I’ve been working on.

A simple double-click on the BOM record opens it up for me to begin necessary edits and update my progress as needed.

All of these activities are performed without having to leave the SOLIDWORKS Manage environment, making my job a lot easier. But how did I know about that BOM creation task in the first place? Well, here’s another area where Manage shines – dashboards and reports.

Dashboards and Reports

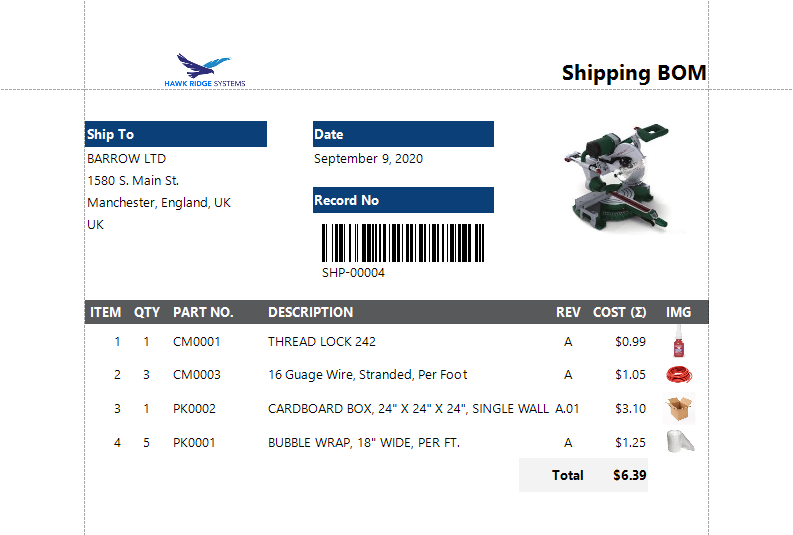

Improving organizational visibility is a key benefit of system consolidation. With SOLIDWORKS Manage, this comes in the form of customizable dashboards and reports that can present live project data for engineering teams, visibility of what’s coming down the pipe for the shop floor, and automatic PDF or Excel outputs for things like project metrics, shipping BOMs, timesheets and more.

That shipping BOM I worked on earlier? SOLIDWORKS Manage can automatically build me a tailored report for distribution once I’ve completed the task:

Once again, the benefits of having your data managed within a single system is clear. For example, management can break down the costs associated with ECNs, and what department or region they originate from. The ability to analyze accurate, live data, as seen below, and make needed adjustments quickly can result in significant time and cost savings.

In summary, there can be tremendous value to an organization looking at consolidating applications and processes, and we’ve taken a look at just a few examples. While shifting from the status quo can be a difficult undertaking, the payback is worth it. For more information on SOLIDWORKS Manage or any of the data management tools available, contact us at Hawk Ridge Systems. Thanks for reading!