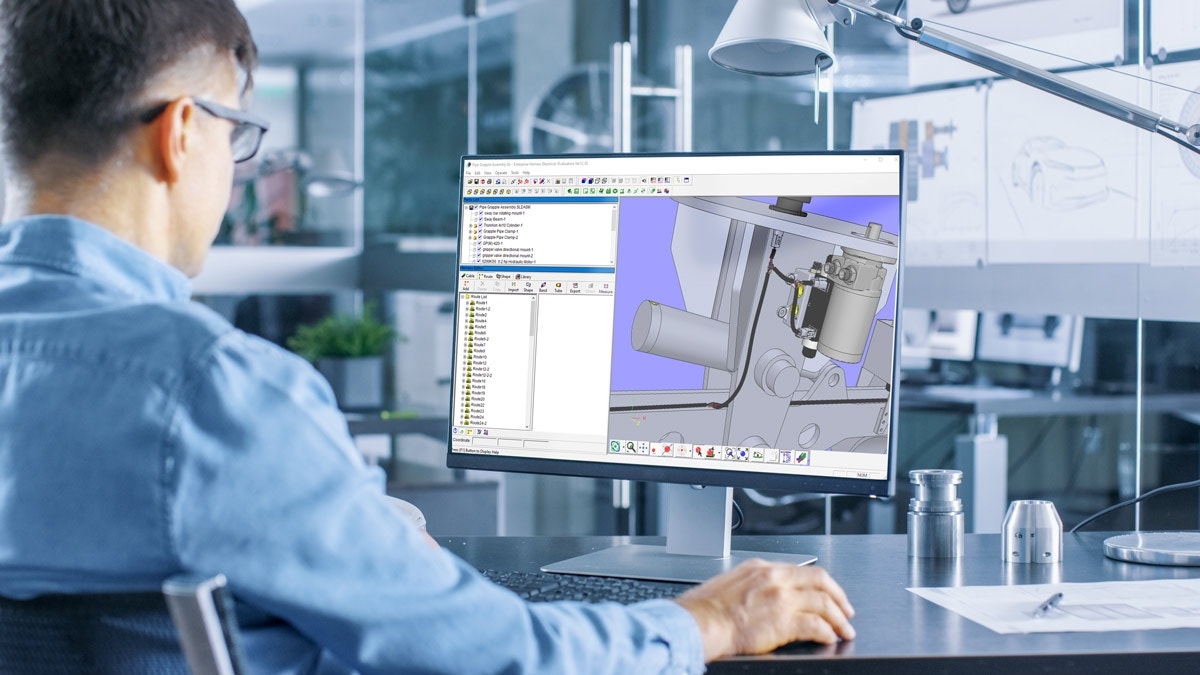

Modern design processes have a lot of complexity, with multiple design disciplines all contributing to the development of products that are routinely more complex than anything that has come before.

One of the most common multidisciplinary intersections is between the electrical and mechanical teams, with electrical teams specifying circuits and connections to make a product work, and a mechanical team bearing responsibility for how those wires are routed throughout the system and captured in the product documentation.

Out of This World Harness Design with Loft Orbital

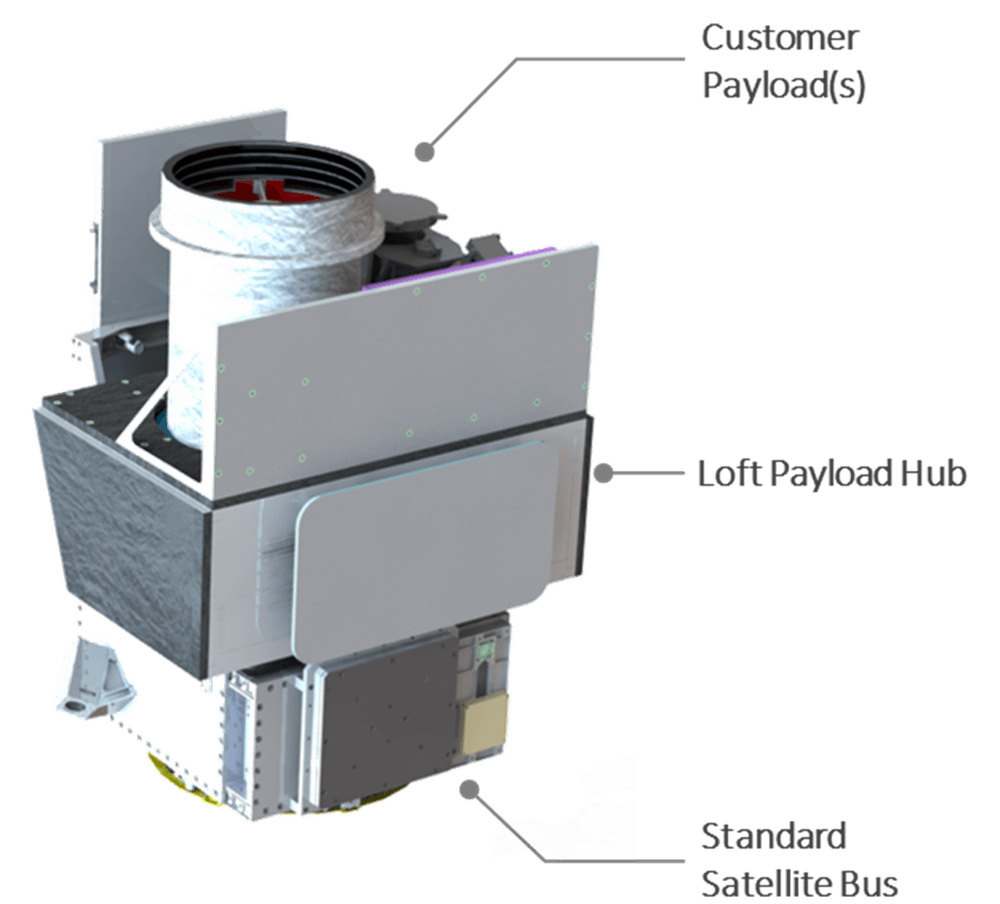

Our customer, Loft Orbital, is no stranger to this challenge. As a leader in providing companies with access to space, they design and develop complex satellites and must incorporate several customer systems, including multiple data types and connectors. With customers ranging from startups to government entities, they are charged with needing to model and produce products quickly for quarterly launches.

Loft Orbital had tried using 3D sketches, but those tended to break with such complex requirements. To facilitate their harness design process, Loft Orbital chose to implement Enterprise Harness to add wiring and harnessing throughout the satellite model.

Introducing Enterprise Harness

Compared to conventional approaches in mechanical CAD, Enterprise Harness provides a simple and clean way to route cables and connectors through the 3D environment. With hundreds of cables in every satellite, being able to do this quickly and easily is critical to enabling rapid project turnaround for Loft Orbital.

Enterprise Harness is unique in that it allows the 3D routing process to take place around and through a light representation of the model – eliminating the performance issues that can burden wire routing through complex models in mechanical CAD. It also doesn’t require any specialist mechanical CAD knowledge, meaning that both electrical and mechanical disciplines can contribute to the work, and make changes.

The Loft Orbital Story

To learn more about Loft Orbital’s use of Enterprise Harness, and to explore how the solution might help your workflows, check out the recorded webinar below.

Want to explore Enterprise Harness or other electrical design solutions in more detail? Contact us at Hawk Ridge Systems today!