Many design engineers in the industrial equipment industry face challenges with customized products that fit the customer’s requirements and comply with safety regulations. They also experience a slow and sequential machine design process. Typically, designs start with a concept, then designing, testing, and refining. But this type of linear process can lead to delays and inefficiencies, especially if you have a high demand for your product.

Let’s talk about why that is and two ways you can speed up your design process.

3 Reasons Why Your Design Process Is Slow

Most industrial equipment design processes are highly serial — meaning designers create machine designs in a linear, step-by-step operation. A serial design process is not necessarily bad, but it’s inefficient and may be unsustainable in the long term.

At some point, you may want to reassess areas where you experience slowdowns. Here are three common reasons why your process may need updating.

1. You Have Dependencies

With each step dependent on the previous steps, you can encounter significant delays, which can become time-consuming for everyone involved.

Consider the traditional process starting with conception. You would first come up with an idea and perhaps even the logistics of how the product would come to life. You get the green light to go ahead and get to designing. Once you get it to a good place, you begin the testing and refining phases. And finally, you move it along to quality checks and manufacturing.

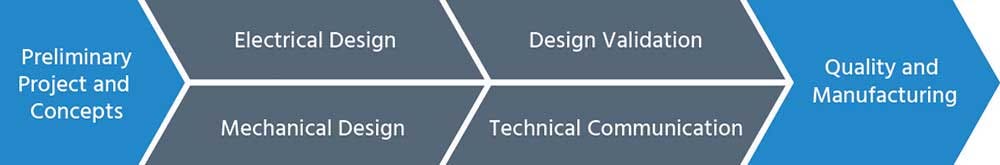

A Typical Serial Design Process

It’s very simplified, but the idea is serial processes often can create dependencies, bottlenecks, and downtime. In other words, if one stage is blocked, another stage will experience a waiting period.

2. You Experience Multiple Rounds of Revisions, Prototyping, and Testing

Serial processes often don’t leave room for multiple rounds of revisions, prototyping, and testing, which can be tough to gauge how many rounds you’ll have and how long they will be. In most cases, you have to go with your best estimate for each stage and the overall project completion date.

If your process doesn’t account for revisions, prototyping, and testing, you can see delays and bottlenecks drawing out your project. You may also experience your team having to deprioritize tasks to work on unexpected refining and testing needs.

3. Your Customers Require Custom, Built-to-Order Equipment

In industrial equipment designs, it’s common to get orders for custom-built machines. Custom products often come with higher profit margins, so it is generally worth the extra time and effort.

Because these custom orders often take a base model design and apply a variety of small changes to the machine, it can significantly impact your time-to-market when you receive several orders.

Your design team will need to work closely with the client to ensure the machine meets their expectations, and design changes are often done manually and go through several iterations. With one custom product, it may be easy to implement into your process, but if you have more, it can be challenging to manage, and you may need to delay other projects.

If your designers can create these similar-yet-different designs more efficiently, you can reduce the time and money it takes to produce multiple built-to-order products.

2 Approaches You Can Take to Streamline Your Process

The slow serial design process can frustrate designers and customers. Designers want to produce a high-quality product and get it to the release date with as few issues as possible. Customers seek faster lead times, reduced costs, and increased customization.

You can create a more efficient design-to-manufacturing process using integrated tools. Integrated software can help you improve accuracy, increase efficiency, and speed up the time it takes to design and manufacture a machine.

Here are two approaches using integrated technology to help streamline your process.

1. Redefine Your Design-to-Manufacturing Workflow

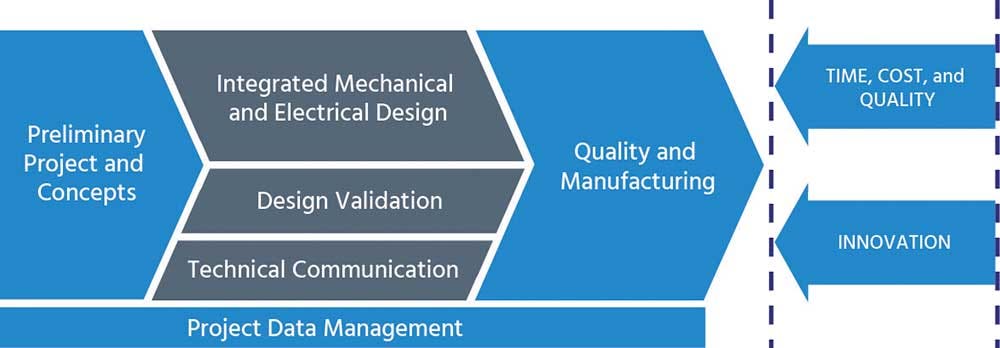

Your design-to-manufacturing workflow can be less serial and more parallel — meaning your team can do multiple tasks simultaneously. When your process is more parallel, several stages are in motion at once, reducing the number of dependencies, delays, and bottlenecks.

To move toward a parallel process:

- Examine how your team communicates and collaborates. By talking to your team, you may find more slowdowns.

- Identify which stages can move forward without fully completing one task before moving to the next.

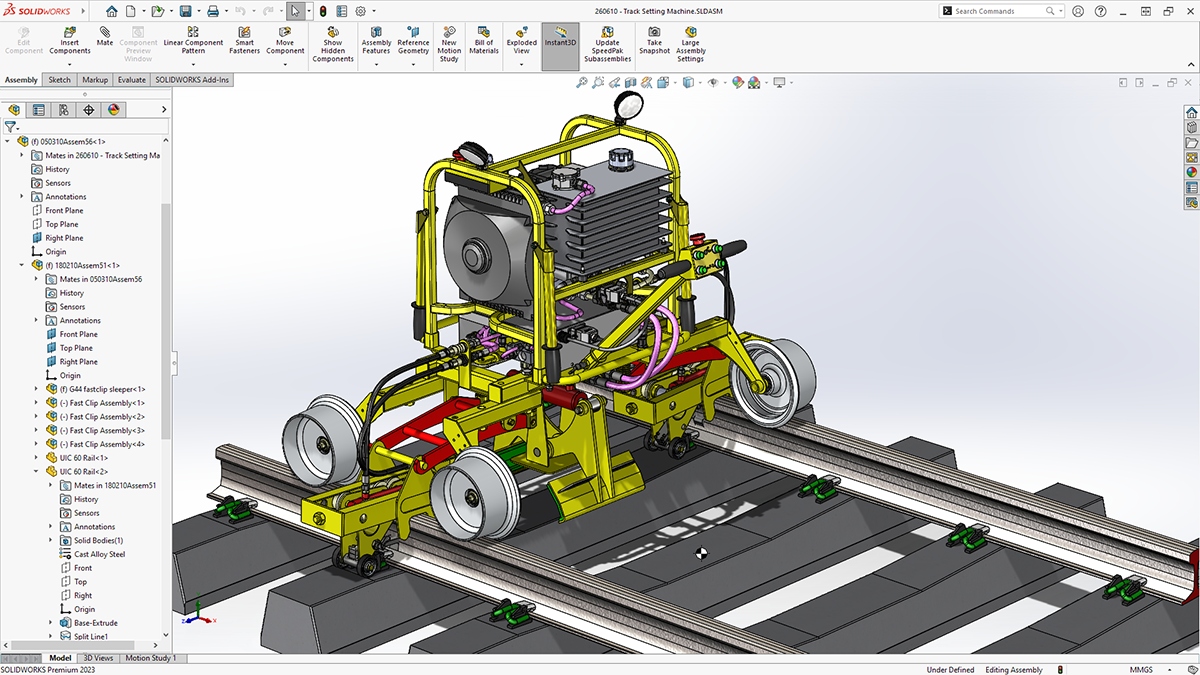

In most cases, machine design processes have several opportunities to become parallel. For example, if you look at SOLIDWORKS products, they have incorporated multiple design aspects in a more concurrent process. You can manage your product lifecycle, create technical and visual documentation, integrate electrical and mechanical designs, and validate designs using simulation before manufacturing.

An Integrated Design Process Using SOLIDWORKS

SOLIDWORKS offers engineers an entirely integrated design ecosystem, linking design files across multiple tools to keep the designs up to date in real time. For instance, designers can create models in 3D CAD and run simulations simultaneously to predict the machine’s performance. You can reduce the rounds of physical prototypes, which are often expensive and time-consuming to produce.

The same can be done with the teams creating electrical schematics or technical documentation. The electrical designs or documentation are automatically updated when design revisions are made in the original 3D CAD file. This reduces the time spent on error-prone manual updates.

In a typical serial process, steps depend on other steps before the product is manufactured, resulting in a longer time-to-market than using an integrated workflow.

2. Automate Custom, Built-to-Order Equipment Needs

Many serial processes don’t incorporate custom equipment needs that machine designers often are tasked with handling. If your customers require customized products that require you to create many similar-yet-slightly-varied designs, you might find yourself in a time-consuming iterative loop.

Design automation software, such as DriveWorks, can help cut down on the tedious and repetitive design tasks associated with custom-built machines. Automation also helps to reduce errors since most design modifications are manually done.

Using DriveWorks, you can automate:

- Creating new design files based on rules you previously set up, so there’s no risk of accidentally overwriting your master design file.

- Creating drawings for manufacturing, including all necessary views and annotations.

- Creating custom-branded documents, including quotations and bills of materials.

![]()

When you automate these design tasks, your process for custom-built orders will naturally speed up while maintaining design accuracy and quality — thus improving your overall profitability.

Integrated Processes That Work for You

As product designs become more robust and intelligent, your design process will need to transform, too. Serial processes are often slow and may become unsustainable in the long run. With a more integrated design workflow, you can keep up with the growing industry and customer needs. You can find several tools and software solutions to bridge the design to manufacturing stages better and faster. Ultimately, you and your team can streamline your design process by bringing key players, like your customers, into the design conversation early on and reducing production delays.

If you have questions about maximizing efficiency with a fully integrated design-to-manufacturing workflow, contact us at Hawk Ridge Systems.