Markforged composite printers are able to inlay continuous strands of fiber within the plastic matrix of 3D printed parts using Continuous Filament Fabrication (CFF). Depending on which fiber type is being used, this can greatly alter the mechanical properties of 3D printed parts that are created by Markforged machines. Certain Markforged printers are capable of inlaying Carbon Fiber, Fiberglass, High Strength High Temperature (HSHT) Fiberglass and Kevlar.

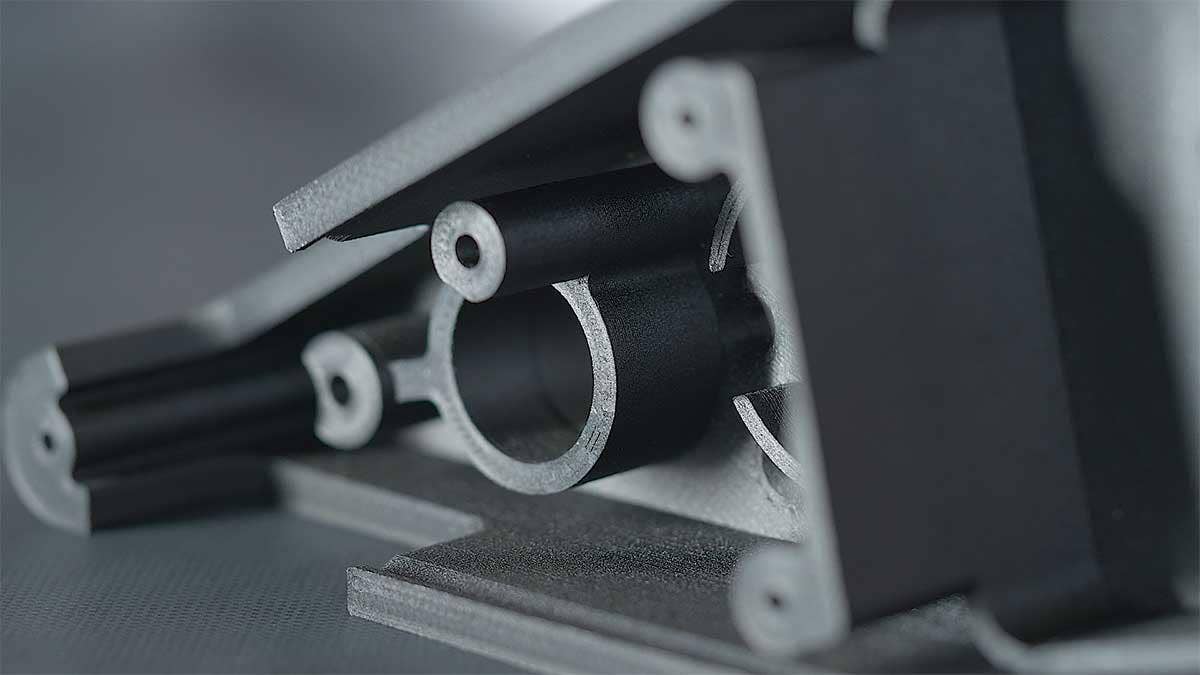

An example of how Markforged printers are able to place continuous strands of fiber into a part.

Even experienced Markforged users can run into challenges when determining which fiber is appropriate for their application. We’ll take a look at the properties of each continuous fiber type, as well as reviewing a few case studies that show the benefits of all fibers.

Fiber Properties

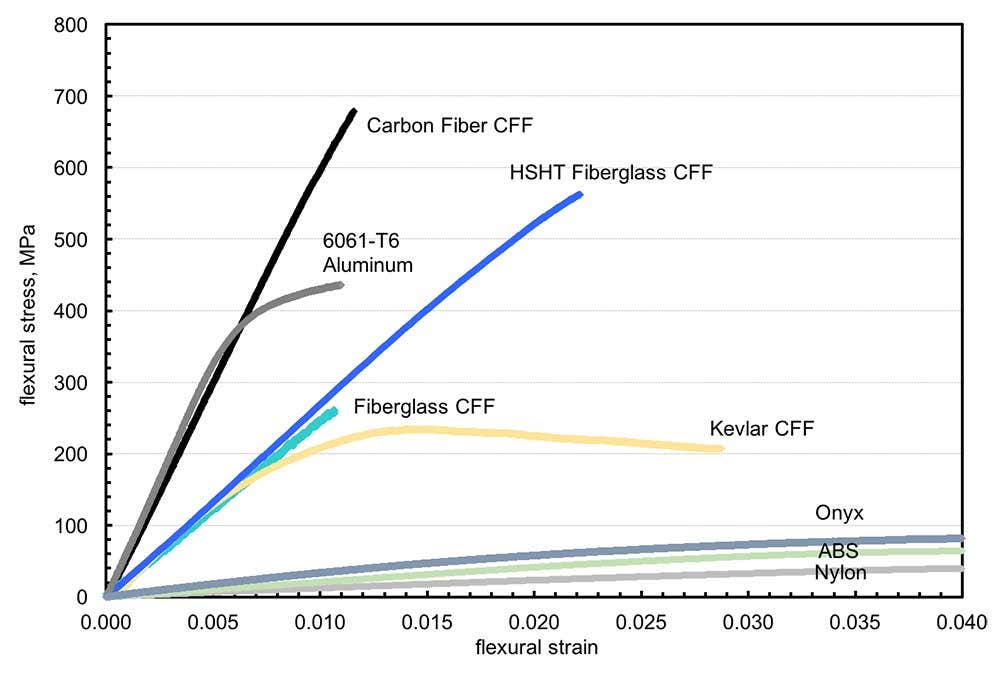

Before inlaying a Markforged part with continuous strands of fiber, it is important to understand the general mechanical properties of the available fibers. To do that, here is a flexural modulus graph that compares Markforged materials to other manufacturing methods.

As shown in the above chart, the Markforged thermoplastic Onyx is already stronger than most commonly used 3D printing materials. However, when continuous strands of fiber are placed in an Onyx part, the strength of said part can increase dramatically. Let’s briefly go over some of the benefits for each fiber type.

- Carbon Fiber: As the stiffest of each fiber type, Carbon Fiber is able to withstand a significant amount of stress. In fact, parts that are inlaid with Carbon Fiber can be stronger than an identical part that was manufactured out of 6061 Aluminum. This is the fiber to use if you need the strongest part possible.

- Fiberglass: Despite being the lightest of the fiber types, Fiberglass is still able to add significant strength to Markforged parts. It also is the cheapest fiber type. In terms of applications, this fiber will be ideal for parts that do not need the stiffness of Carbon Fiber but do need strength in addition to Onyx.

- High Strength High Temperature (HSHT) Fiberglass: HSHT Fiberglass is an ideal fiber for environments that require both high strength and high-temperature resistance. The heat deflection temperature of this fiber is similar to that of Onyx, which sits at 145C. The combination of strength and higher heat deflection make it one of the more unique fiber types.

- Kevlar: Lastly, Kevlar completes our list as a fiber type has great impact and abrasion resistance properties. Among the four fiber types, it is most able to bend back to its original shape after deforming. Kevlar is great to include in parts that will take a lot of abuse, including those that are subject to repeated load-bearing conditions.

To learn more about the properties of Continuous Filament Fabrication and the fibers that can be placed inside Markforged parts, feel free to visit the Markforged Composites Information Page.

Example Use Cases

Now that we have a general idea of what each fiber type can do, let’s delve into some customer case studies. Each case study will highlight a customer’s application that used CFF to enhance their in-house manufacturing capabilities.

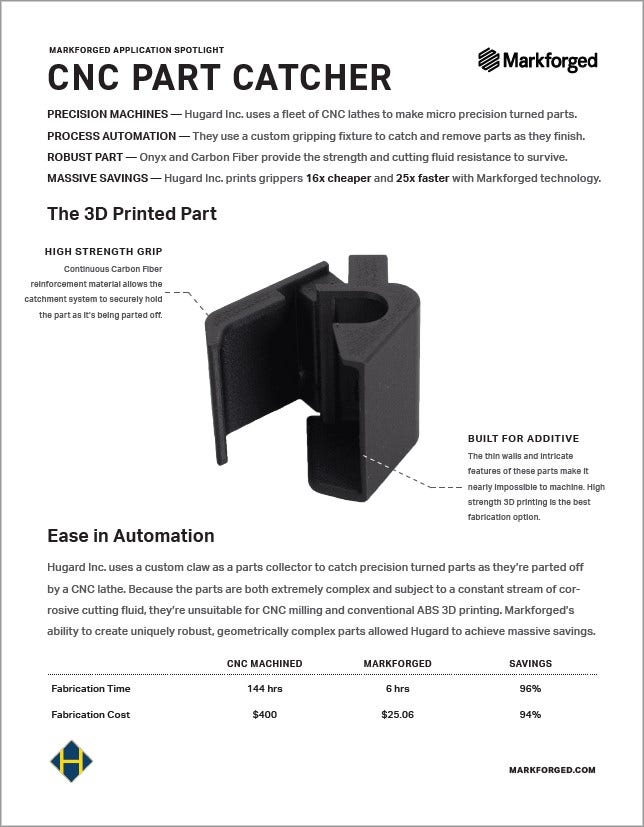

For our first case study, we’ll take a look at Hugard Inc., who used a Markforged printer to 3D print custom grippers that hold CNC parts after they are processed. Hugard Inc. elected to utilize Carbon Fiber for their part, due to the strength needed when handling their components.

Click on this preview to download the Hugard Inc. case study. Content courtesy of Markforged.

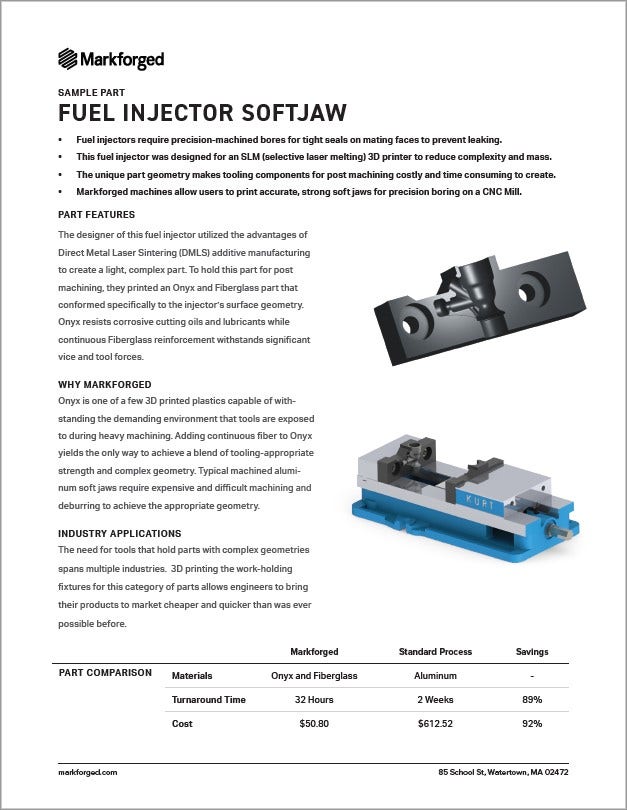

In our second case study, we’ll look at a softjaw that was printed to hold a custom metal component. The geometry of said softjaw made it expensive and time-consuming to produce via CNC. This application uses Fiberglass to give it the strength needed to hold components in place, while also being much cheaper and faster to produce when compared to traditional manufacturing methods.

Click on this preview to download the softjaw case study. Content courtesy of Markforged.

The third case study we’ll look at focuses on Humanetics, who used an Onyx and HSHT Fiberglass mold to replace their traditional silicone process. The HSHT fiberglass gave these molds the temperature resistance and stiffness needed to withstand their target temperature. The Onyx base is also able to be printed with precision tolerances.

Click on this preview to download the Humanetics case study. Content courtesy of Markforged.

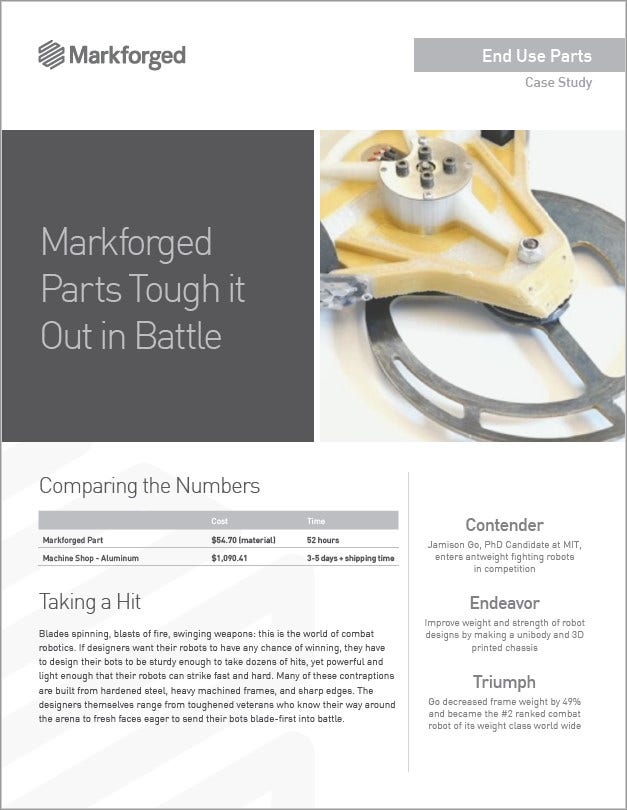

Lastly, our Kevlar centric case study will look at combat robots that were printed by CFF. In the world of battle bots, weight is almost as important as the ability to survive extreme conditions. Markforged was able to print a Kevlar filled robot that was not only light but also able to withstand repeated impacts and loads.

Click on this preview to download the combat robotics case study. Content courtesy of Markforged.

For more information or to get pricing on Markforged printers, be sure to contact us at Hawk Ridge Systems today. Thanks for reading!