Engineering Spotlight: Andrew Garchik

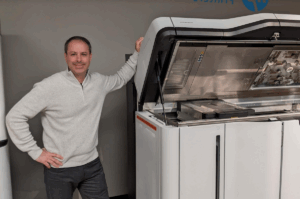

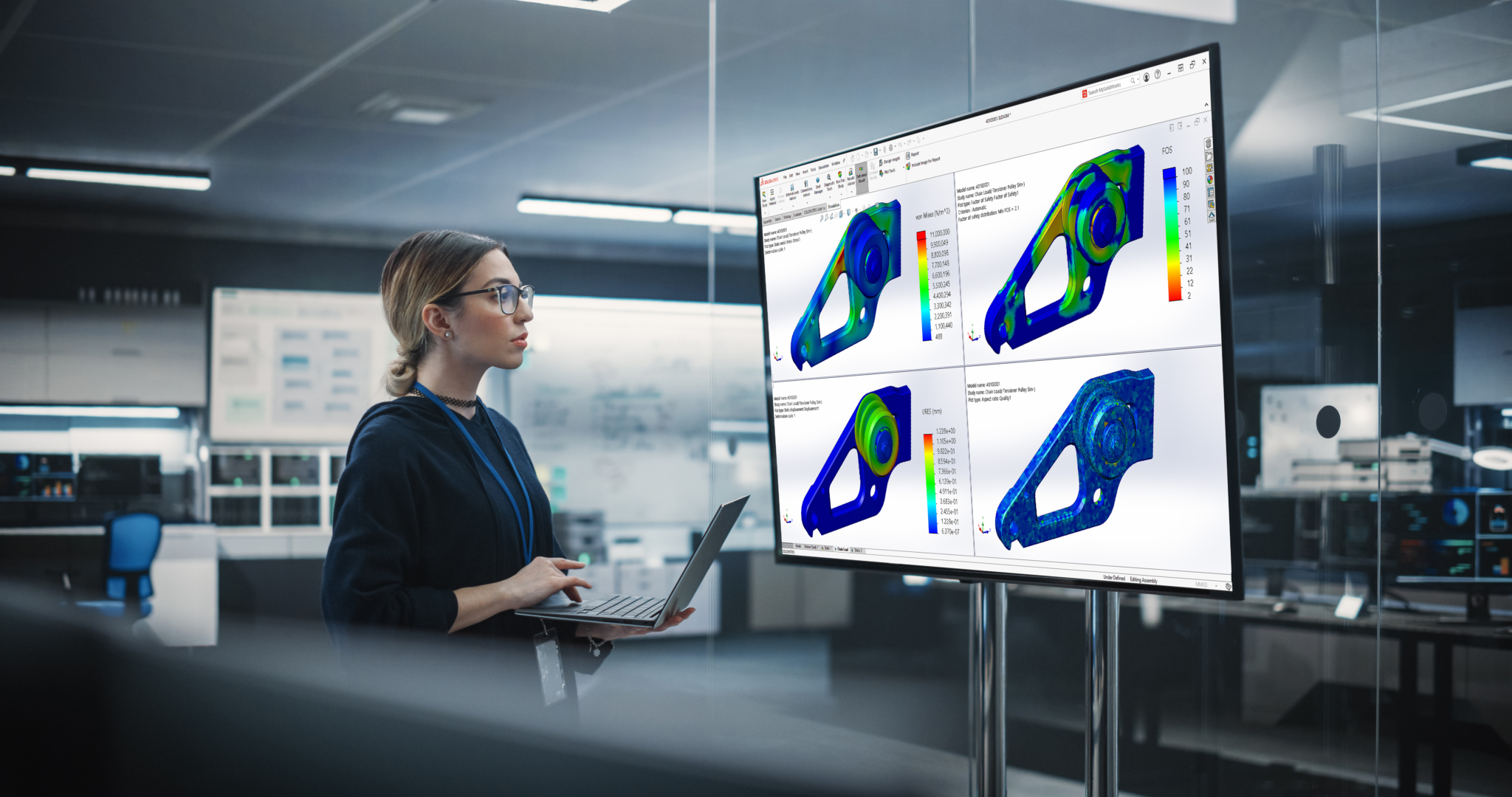

Andrew Garchik works with manufacturers to reduce lead times, cut part costs, and bring outsourced parts in-house using new additive manufacturing technology that 3D prints metals, carbon fiber and other high-strength materials. He helps new customers evaluate the technology, identify applications, train operators and designers, and supports them post-investment.

Why Engineering? When did you know you wanted to pursue engineering and design?

When I first graduated high school, I actually had no idea what I wanted to do. My grades weren’t top–notch, so I wound up going to an agricultural SUNY school called Cobleskill in upstate NY. I studied hotel management and cooking for a year, until fate interceded. One evening I woke up to flames coming through my window as the entire house I was renting burned down. After that, I decided to move to FL the next semester. I studied liberal arts, got on the Dean’s List, which then allowed me to transfer to USF in Tampa, which is where I got my engineering degree. I didn’t know what to major in, but I knew that math and science came naturally to me, so I chose engineering.

Why Hawk Ridge Systems?

Like many, I didn’t choose HRS, HRS chose me. Originally, I worked for Design-Point, which was bought by HRS. It’s a long story, but after college I didn’t go into engineering. In another lifetime I was a realtor selling residential real estate in the Fort Lauderdale area. I started in 2006 and left the field in 2011, so I saw the worst of the 2008 housing crisis. After that was over, I decided to move back to NY and was living in NYC. My idea was to use my engineering degree and real estate sales experience to land a high–paying technical sales job. However, my sales experience wasn’t the right kind for that, so I wound up going into sales to get more experience. I was a gourmet soda salesperson for seven years before finding a job listing at Design-Point for 3D printer sales.

Advice to people considering engineering as a career?

The first two years are easy if you’re good at math, but the second two are very difficult and require a great deal of work. Be ready for that. Also, just because you have a degree doesn’t mean anyone will want to hire you. Make sure you do a co-op or internship and actively build your resume with various skills prior to graduating.

What’s the most fun or quirky project you’ve ever worked on?

The first thing that comes to mind is the cutter body project. I copied a Markforged use case for Guhring UK and printed a cutter body for a mill with conformal coolant channels in metal. I was able to actually test it on a mill, and we hogged out some aluminum one day which was really fun. I also made a mockup of a mill that shows off the application that we use as a centerpiece at tradeshows now.

Favorite side or pet project?

One of my favorite side projects is my family-run business. It’s not exactly a side project, but over covid, I took a second job as an adjunct professor working remotely for a customer Catholic University of America. They needed an elective 3D printing course to fill out their program, so I created one for them on printing in composites and metals. I taught for one semester but two jobs was one too many.

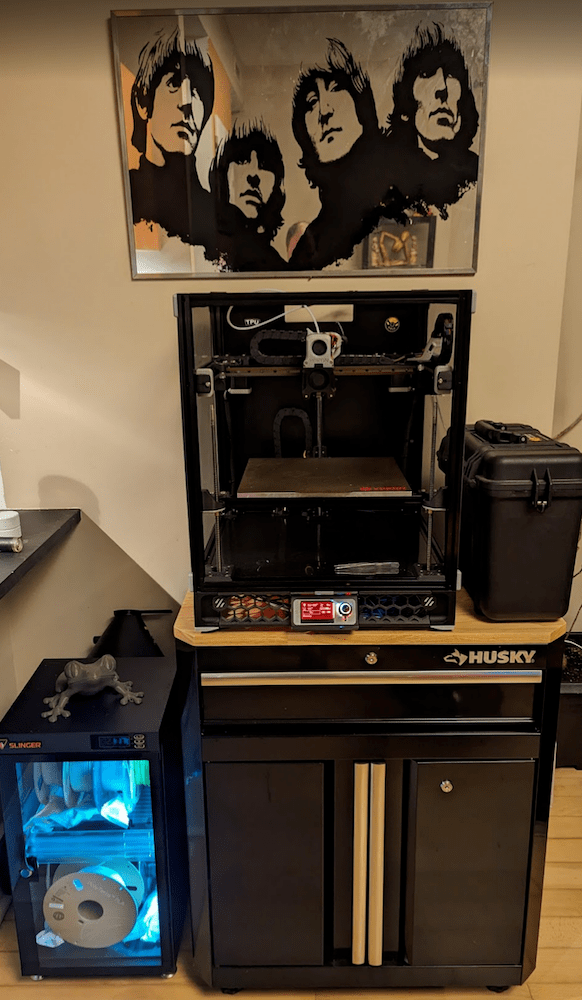

This is my home 3D printer set up and a fun side project I did. It’s a 3D-printed remote control holder.

Favorite client engagement? Why? What problem did you get to help solve?

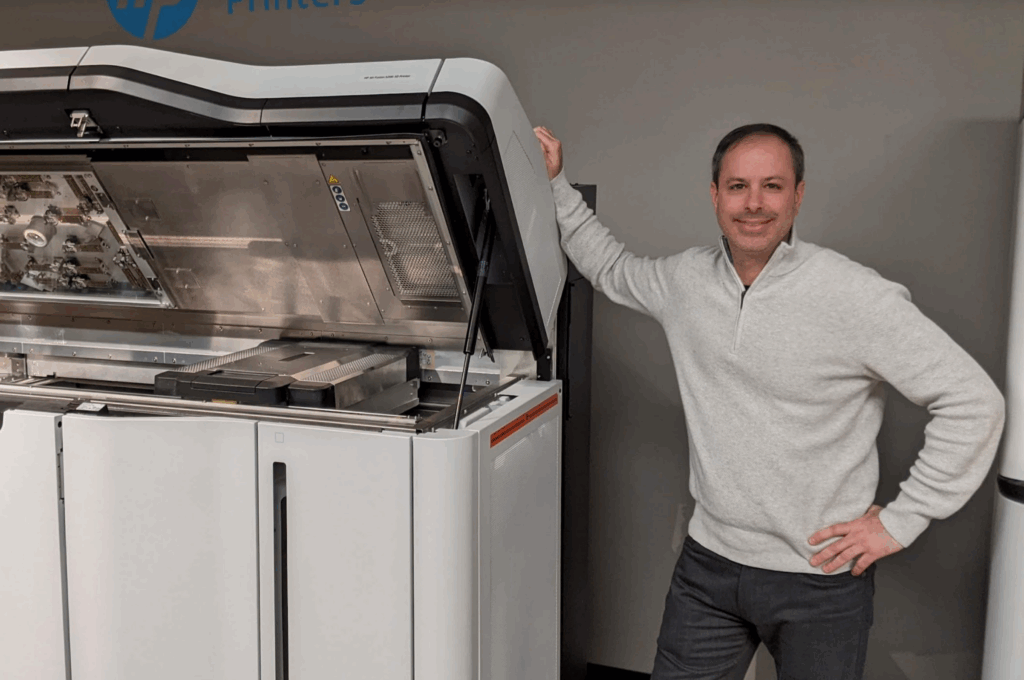

I’ve really enjoyed working with our best customers on their FX20’s installing, training, and repairing. The customers that have these machines are fun facilities to visit that do amazing things for the aerospace, military, healthcare industry, etc. So, visiting these facilities to work on these machines has been very rewarding.

Recent work or side project that shows why you love engineering?

My family has a 20 ft open bow speed boat that’s now 20 years old, so everything is breaking and disintegrating. One day, my mom walked in and said, “This plastic bracket broke and they don’t sell them anymore so I can’t figure out how to replace it.”

My response was “YES!!!” Since then, I’ve printed brackets, a stereo housing, a small storage bin for the glove box, and a cap for the light pole. I also just recarpeted and reupholstered the seats, so my restoration project is coming along.

What are you reading/watching/learning/playing currently?

I don’t read much anymore but my favorite book is the Foundation Trilogy by Isaac Asimov. They recently made a Foundation show on Apple (get to season two, it’s worth it), and I also like HOTD.

What do you want to learn next?

How to winterize my boat without paying someone.

Favorite engineering or dad joke or meme?

One time I went to a party but had no idea that there was a 70’s theme. I shaved a mustache and chops into my beard, and opened my shirt and I fit right in. I made this meme afterwards to crack up my cousins:

What’s a recent engineering trend or innovation you’re excited about?

I think that augmented reality will start to show up in our field so that would be an interesting product to sell. 3D printing in homebuilding is already here but will likely be a big deal in the future.

Where can people follow you online or see more of your work?

I don’t post much online, but you can follow me on LinkedIn!