Like many manufacturing methods, 3D printing is a great tool for improving the product development cycle. Even if the final method of producing a product is already set in stone, bringing 3D printing in-house as a supplemental solution can allow an organization to improve the efficiency of their existing processes and hardware. In this article, we’ll cover three additive manufacturing solutions that can help enhance the utilization of existing industrial equipment and improve the product development process.

1. The FX10 – Carbon Fiber-Reinforced Parts by Markforged

The FX10 is the newest Industrial printer from Markforged, and it features significant improvements over their extremely capable X7 system. This includes a larger build volume for higher throughput, a heated build chamber for faster print speeds, and automatic material changeover to enable lights-out production. You can read our FX10 Announcement Blog if you would like to learn more about what this excellent machine is capable of!

On the materials side, carbon fiber-reinforced parts printed by the FX10 are extremely versatile in an industrial setting. These composite parts can have a higher strength-to-weight ratio than aluminum, making them ideal for metal replacement applications such as jigs, fixtures, and other tooling that would normally occupy an internal queue or be otherwise outsourced. The exterior Onyx matrix is highly resistant to many different chemicals, meaning that FX10 parts can maintain their strength while being exposed to industrial chemicals such as oils or machining coolant.

The parts printed by an FX10 are also partially hollow by default, which creates much lighter geometry that might otherwise be impossible to produce via other manufacturing methods. For applications where weight is a critical factor to operation speed – such as part pictures or end-of-arm effectors – replacing traditional components with strong and lightweight Markforged equivalents can be a game changer.

Lastly, the FX10 requires no additional post-processing equipment or power supply beyond a wall outlet. This results in a machine that can be placed almost anywhere on the factory floor without any considerations for additional equipment.

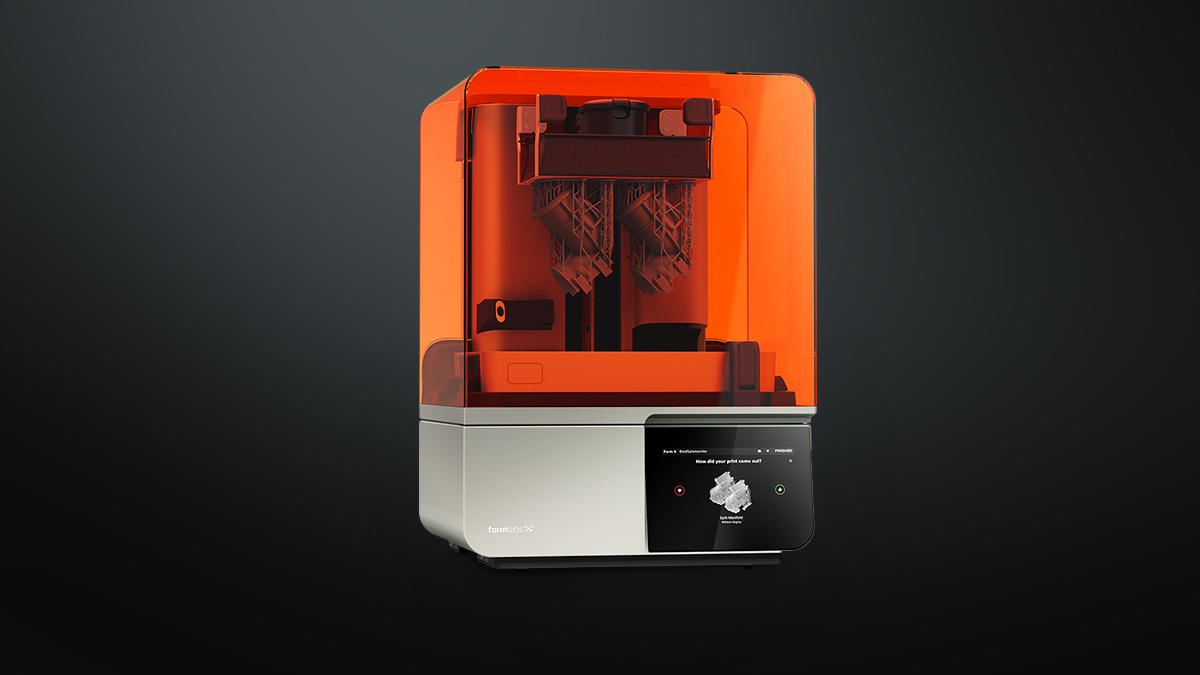

2. The Form 4 – Versatile SLA Printing by Formlabs

Continuing the theme of new machines that improve on the strengths of their predecessors, our next 3D printer that can supplement an industrial setting is the Form 4 from Formlabs. While the latter part of that sentence is certainly a tongue twister, the benefits of the Form 4 are not – the system is faster, more accurate, and cheaper to operate than any prior SLA system built by Formlabs.

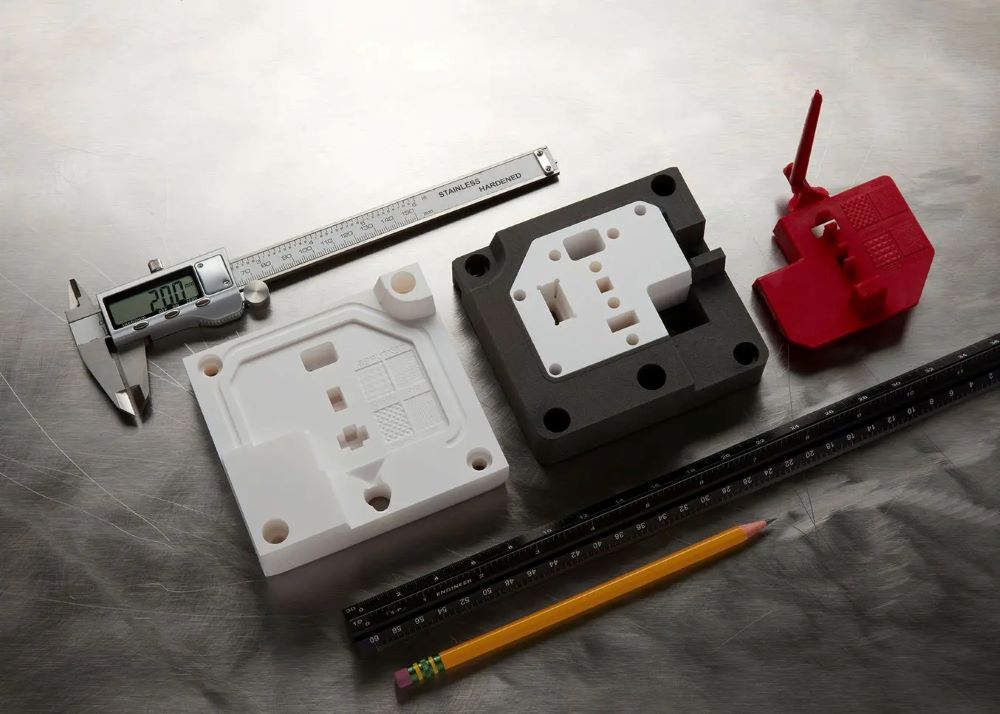

One of the biggest strengths that Formlabs brings to the table with their SLA systems is their material library, and the Form 4 is no different in that regard. Form 4 operators will enhance their in-house industrial capabilities by using different specialized resins. One such example is the printing of mold cores, insert molds, or thermoform molds using stiff resins such as Rigid 10K. The tooling of molds is a common manufacturing pain point due to turnaround time and cost, so being able to 3D print functional molds that are accurate and have a smooth surface finish can be a great benefit to organizations that have localized injection molding capabilities. With its speed improvements, the Form 4 can cut these turnaround times even further.

Of course, the Form 4 is also able to print with several specialized engineering resins to meet the requirements of more unique or targeted applications. The ESD resin is a great solution for work holdings that need to be ESD-safe, making the Form 4 a great supplement for electronic assembly or manufacturing lines. Elastic 50A is a perfect solution for creating parts that interact with fragile or easily scratched components. The self-extinguishing Flame Retardant resin is perfect for any part that must have low Flame Smoke Toxicity (FST) ratings, such as ducting or casings that interact with ignition sources.

Like their prior SLA printers, the Form 4 can also be a perfect functional prototyping tool due to the strength and surface finish of its printed parts. Printing prototypes allows other industrial equipment to be used for critical tasks while keeping product development on track.

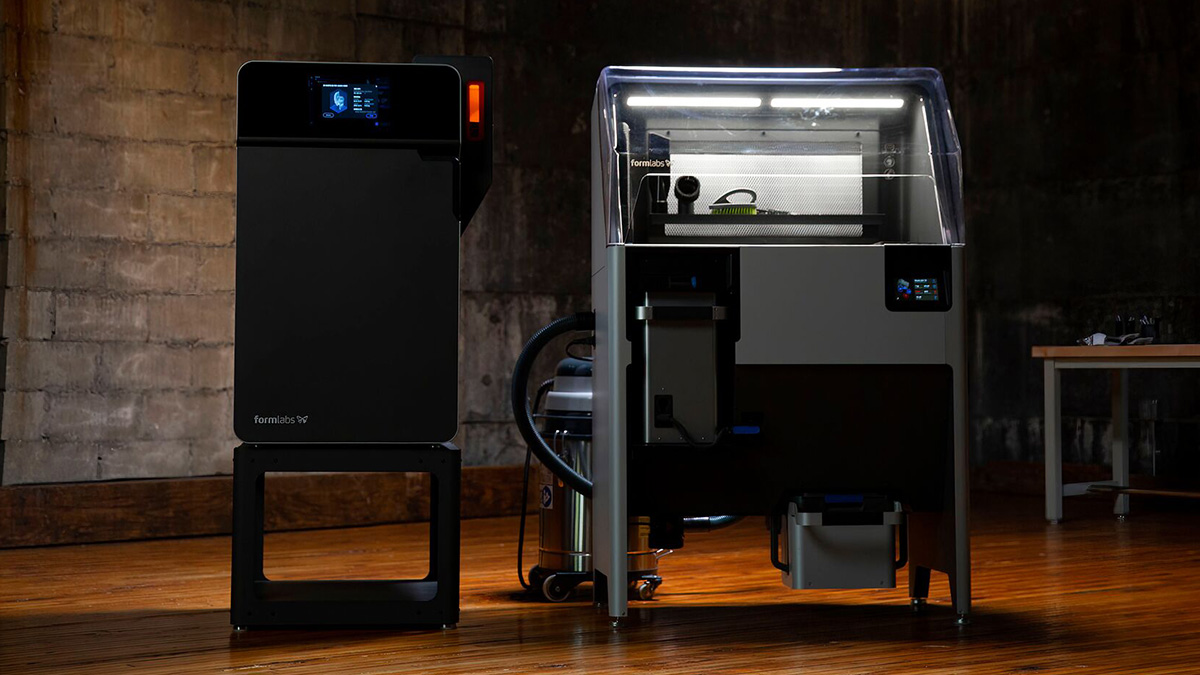

3. The Fuse 1+ – Accessible and Versatile Powder 3D Printing

Last on our list of 3D printers to consider is the Formlabs Fuse 1+. It’s a powder-based Selective Laser Sintering (SLS) printing solution. In Additive Manufacturing, powder–based 3D printers offer a unique advantage – unused powder will support printed part geometry throughout a build. Since the entire build volume of a Fuse 1+ job is self-supporting, users can take full advantage of each print by placing parts anywhere that they can fit. This also means designers can take a creative approach to part design via complex lattice structures or topology optimization, which may result in geometry that cannot be produced any other way.

Like the Form 4 in our previous section, the Fuse 1+ also has a wide range of materials that users can select from. These include Nylon 12 (PA12), Nylon 11 (PA11), Polypropylene, and TPU. Many parts printed on the Fuse 1+ are near-isotropic and are also watertight, making them excellent candidates for geometry that needs to contain or resist fluids such as tooling with internal cooling channels. The Fuse 1+ is also a great assembly reduction tool, allowing designers to reduce the total number of components needed in any given project. Of course, SLS parts are also great candidates for a wide range of manufacturing aids, both simple and complex.

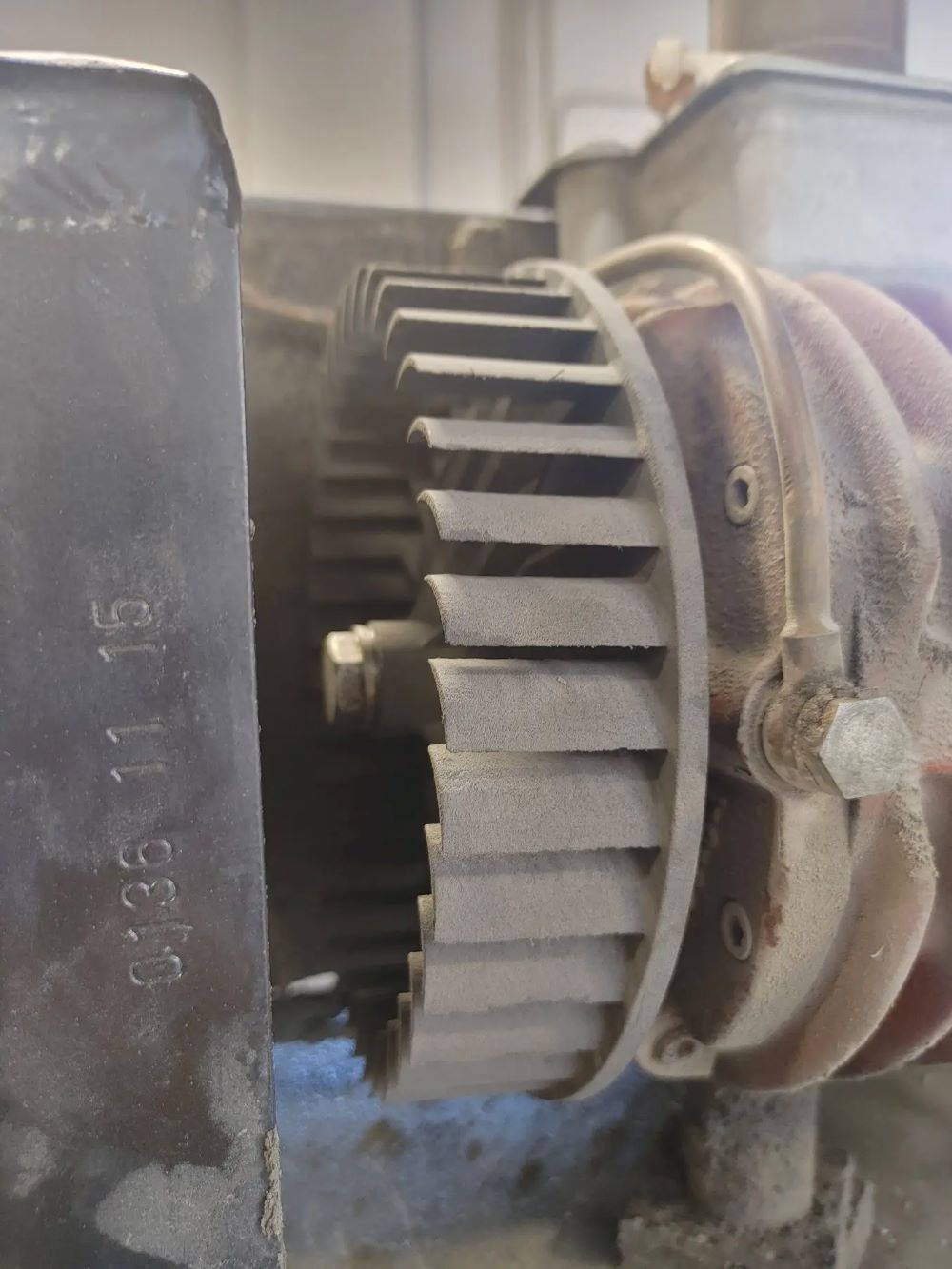

The Fuse 1+ is also a great tool for ensuring that internal equipment remains operational using printed replacement or spare parts. In the case of Productive Plastics, a single impeller failure meant that one of their internal thermoformer machines would be down for 6 to 8 weeks while a replacement was manufactured. The Fuse 1+ was able to print the entire replacement impeller overnight and saved the organization $30,000 in machine downtime. In this and many other instances, SLS printing plays a huge role in creating complex geometries without design changes.

Of course, the Fuse 1+ can also act as a bridge to production solution or supplement current production methods. Like the other machines we have discussed in this blog, this can reduce the queue of existing equipment and help reduce project risk by keeping timelines intact.

Thank you for taking the time to read. Keep an eye on the Additive Manufacturing section of our blog to stay up to date with the latest in 3D printing, and feel free to contact us today if you have any questions!