Markforged just added a new printing system called the FX20. This system is set to be the biggest, fastest, most sophisticated system to ever be released from Markforged. Now Continuous Fiber Reinforcement (CFR) can be added to high-temperature thermoplastic for incredible end-use performance in the most demanding applications.

With this machine, Markforged has entered into a new realm of industrial printing systems bringing with it the quality, consistency, performance, and amazing user experience we have all come to know and rely on, day in and day out. Now more than ever, Markforged can serve industries such as automotive, aerospace, defense, oil, and gas in harsh, high-temperature environments with the FX20. Let’s dive in and review what this machine has to offer.

3D Printing with High-Temperature Thermoplastics

The first major benefit of the FX20 is the ability to run higher temperature materials up to 200C, like Ultem (PEI). This is accomplished through higher temp nozzles and a heated build chamber to handle these performance grade thermoplastics. Parts from the FX20 can withstand high heat, flame, and harsh chemicals much better than before. The print process for thermoplastics will be fused filament fabrication (FFF), which is consistent with previous Markforged printing systems.

- New Material: ULTEM 9085 (FFF)

- Operating Temperature Capability: 200C

- Other Supported Materials:

– Onyx (FFF)

– Onyx ESD (FFF)

– Onyx FR & FR-A (FFF)

– Nylon (FFF)

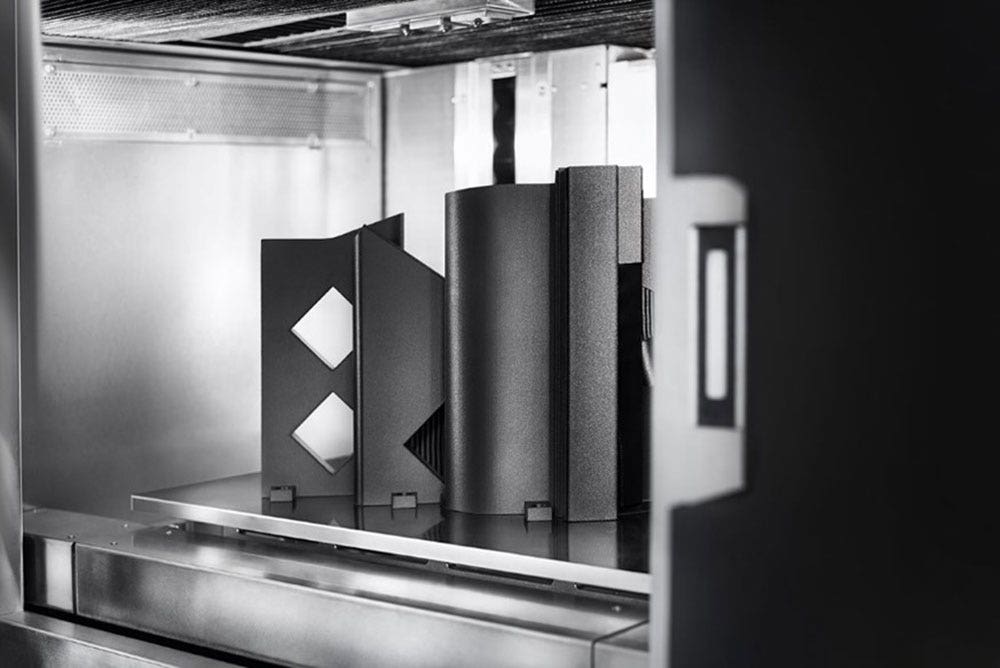

Large Build Volume

The FX20 features the largest build volume of any Markforged machine with an 80-liter build volume – approximately 4 ½ times larger than the X7 system. A larger print area not only allows for bigger parts but also allows for more parts to be printed at the same time, which is a major production advantage.

- FX20 Build Volume (Multi-Nozzle Builds): 500mm x 400mm x 400mm (80L)

- FX20 Build Volume (Single-Nozzle Builds): 525mm x 400mm x 400mm (84L)

Fast 3D Print Speeds

Faster print speeds are always nice and the FX20 does not disappoint. The average print speeds are approximately twice as fast as the X7 printing with turbo print (fastest X7 print mode) without sacrificing part quality. Layer heights on the system range from 50-250μm, meaning that this machine will be capable of providing that excellent surface finish that we know so well from Markforged printing systems. In addition to fine layer heights, this machine also boasts the tightest accuracy rating in the Markforged fleet at: +/- 125 μm or +/- 0.0015 mm per mm (whichever is greater).

Three Materials Simultaneously

One additional upgrade is that the FX20 has three nozzles rather than the two found on other Markforged machines. Now, three materials can be printed simultaneously. The first nozzle is dedicated to plastic while the second nozzle is dedicated to fiber reinforcement. The third nozzle will be dedicated to a break-away support material used for high temp plastics. The system also has an updated material cabinet that can store and monitor multiple spools of material. The FX20 also supports large 3200CC spools, which is a big upgrade from the 800CC spools on other Markforged machines.

- 3200CC spools

- First Nozzle Plastic Material

- Second Nozzle Fiber Reinforcement Material

- Third Nozzle Support Material (ULTEM Support)

Continuous Fiber Reinforcement

Markforged is well known for continuous fiber reinforcement (CFR) technology that adds metal-like part strength to thermoplastics. With the FX20, CFR can be introduced into high temp thermoplastics to bring much higher strength and rigidity to this new class of materials. Since the FX20 has a larger build volume, now CFR can be added to much larger parts than before.

- Carbon Fiber & FR-A (CFR)

- Kevlar (CFR)

- HSHT (CFR)

- Fiberglass (CFR)

Smartest Platform from Markforged

The FX20 will feature the smartest platform from the Markforged fleet with more data monitoring, analytics, and in-depth system instrumentation than ever before. Over-the-air updates will be available to improve system performance and reliability. Cloud-based analytics will be available on the system with insights that can only be captured through machine learning. And finally, Blacksmith will also be available on the FX20.

There we have it, the FX20 is set to make a major splash in the 3D printing world and I for one can’t wait to start printing with this system. Keep an eye out for future content related to the FX20 in the coming months. For any additional questions regarding the FX20, feel free to contact us at Hawk Ridge Systems today!