Curious about how companies are putting 3D printing technology to the test? Carolina Rubio, 3D Printing Customer Program Manager at HP, has shared a few compelling applications for HP Jet Fusion 3D printers that take additive manufacturing to the next level. Here’s a look at some of the extreme applications that customers are designing and making with HP 3D printing technology.

Kupol Football Helmet – Extreme Sport

Kupol has been innovative in the field of 3D printed energy absorption structures to enhance the safety of sportsmen. They accomplish this through the creation of custom lattice structures to customize shock absorption capabilities inside athletic gear, like this football helmet.

In this example, they are using BASF TPU material, which is an elastomer from the HP Jet Fusion material portfolio. This material is flexible and when printed in a lattice shape, it can absorb a large amount of impact force. By using a clever lattice design, different areas of the helmet can exhibit different levels of cushion and performance. Now, not only can a helmet can truly be tuned exactly for the demands of the application, but the printed lattice structure is much more breathable than traditional padding materials.

Cobra Moto – Extreme Motorsports

Cobra Moto produces premium, race-ready mini motocross bikes for youth to be used competitively. To stay ahead of the curve, they rely on HP Jet Fusion technology to rapid prototype before moving into production.

Parts such as bike fairings, vents, electrical housings, and brackets all can be produced effectively with HP Jet Fusion technology. Polypropylene from HP is proving to be an attractive option for applications such as this for its durability and low part cost. HP 3D printed parts exhibit near identical performance to injection molded components, making it the perfect test or complete replacement for these types of parts.

Super Feet Midsole – Extreme Rebound Resilience

Super Feet midsoles utilize HP TPU material and lattice structures to create optimum rebound and support while reducing the overall weight of the shoe. Similar to the Kupol Football Helmet, lattice structures can be tuned and customized for the proper amount of rebound and shock absorption throughout the midsole. Different mechanical responses can be designed into the part for optimum comfort. Keep an eye out for even further customization in the future as this concept gains more traction in the market. We are already seeing HP Jet Fusion technology heavily used in other footwear applications such as custom insoles.

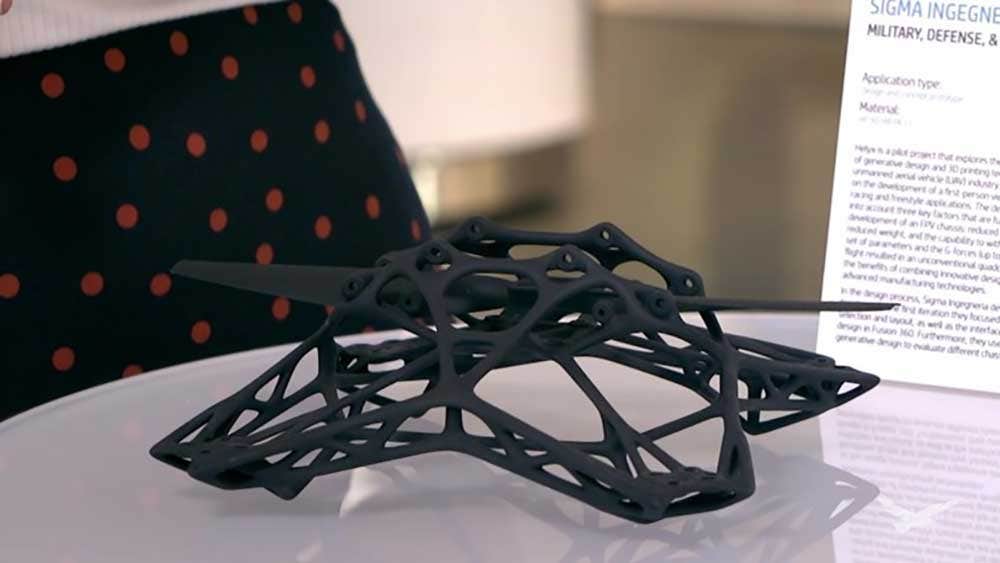

Sigma Drone – Extreme Light Weighting

When designing parts for in-flight applications, reducing weight and air resistance are primary considerations in aircraft design. Sigma Drone developed a first-person view drone using HP PA11 material tuned for racing and freestyle applications.

HP PA11 was a perfect material for providing both structure and impact resistance for the Sigma Drone chassis. Through generative design strategies, external loads and forces can be applied to the drone frame to optimize the shape for a given set of parameters. This drone effectively combines innovative design strategies with advanced manufacturing techniques.

Nivellipso Dental Molds– Extreme Personalization

Orthodontic dental molds are one of the major applications to heavily use HP Jet Fusion technology. When there is a need to produce thousands of unique parts, high volume additive manufacturing with HP Jet Fusion technology is a perfect fit. To produce these molds, a dentist will 3D scan the patient’s teeth, and the scan is then converted into a printable 3D model. That model is then printed as a mold for a thermoforming process.

For one patient, approximately 30 aligners and 10 molds are required. Compared to traditional manufacturing, the total cost savings is ~$600-$1000 per treatment. HP Jet Fusion machines are tuned for high volume production and can produce hundreds of molds in a single build (approximately 420 in the example above).

Nasal Swabs – Extreme Flexibility and Reliability

In the early stages of the COVID-19 pandemic, 3D printed nasal swabs were one of many items that experienced severe supply chain disruption. HP Jet Fusion with PA11 became an excellent solution to solve this problem.

The 3D printed nasal swab was designed and approved for use as a medical device in a matter of weeks highlighting the flexibility of additive manufacturing to fill the gap during supply chain shortages. The nasal swab design benefits from the increased flexibility found in PA11, while its compact shape allows for high quantities to be produced at a very low cost. The thin bristles on the end of the swab can be challenging to print for many technologies, however, HP Jet Fusion technology can achieve highly detailed prints while retaining the strength and durability required for this application.

Extol Fluid Container – Extreme Pressure

Using HP Polypropylene, Extol uses HP Jet Fusion technology to accelerate the design and testing process, which can be very lengthy with traditional methods like injection molding. For this example, Extol brought the overall time to market down from weeks to only a few days by using additive manufacturing.

The fluid reservoir shown in this example was produced as two pieces which were welded together. HP Polypropylene can be welded with traditional plastic weld methods such as hotplate welding. The burst strength of the unit is around 106psi.

Vestas Wind Turbine Blade Holder – Extreme Protection

Vestas is a wind turbine company that designs, manufactures, and installs turbines globally. This part example made from TPU is a bracket used to protect a small portion of a wind turbine blade during handling and rotation specifically from a horizontal orientation to a vertical orientation. Wind turbine blades can be over 60 meters long and brackets made from TPU can protect the blades from scratches and damage.

HP Fusing Lamp Cooling System Ducting – Extreme Temperature

HP also uses Jet Fusion components on the 3D printers that they produce. This example is a series of 3D printed cooling ducts that are mounted on top of the fusing lamps for the HP Jet Fusion 5200. These air ducts are utilized to cool the two fusing lamps located in the printhead carriage of the machine. These ducts have variable sizes internally which helps to balance pressure and provide uniform cooling for the lamps. The ducts are produced out of PA12 material and the internal temperature in the machine reaches approximately 188C, highlighting the ability of printed parts to withstand elevated temperature environments.

Triple Eight Race Car Components – Extreme Aerodynamics

Triple Eight Race Engineering uses HP PA12 to improve aerodynamics on racecars. With the aim of simplifying the manufacturing process as well as enabling customization, Triple Eight utilizes HP Jet Fusion technology to improve aerodynamics and ergonomics for race components. Using 3D printing, they can reduce the weight and improve the performance and usability of components. The design cycles and time to part in hand saving weeks at a time by using Jet Fusion. Cost savings are a major plus, with around 80 percent savings compared to traditional manufacturing.

Well, this caps off our look into extreme applications for HP 3D printed parts. Hopefully, these application examples will help you in your design journey to open up new doors and possibilities for future products.

If you would like to see how HP Jet Fusion technology can improve your manufacturing process, feel free to contact us at Hawk Ridge Systems today!