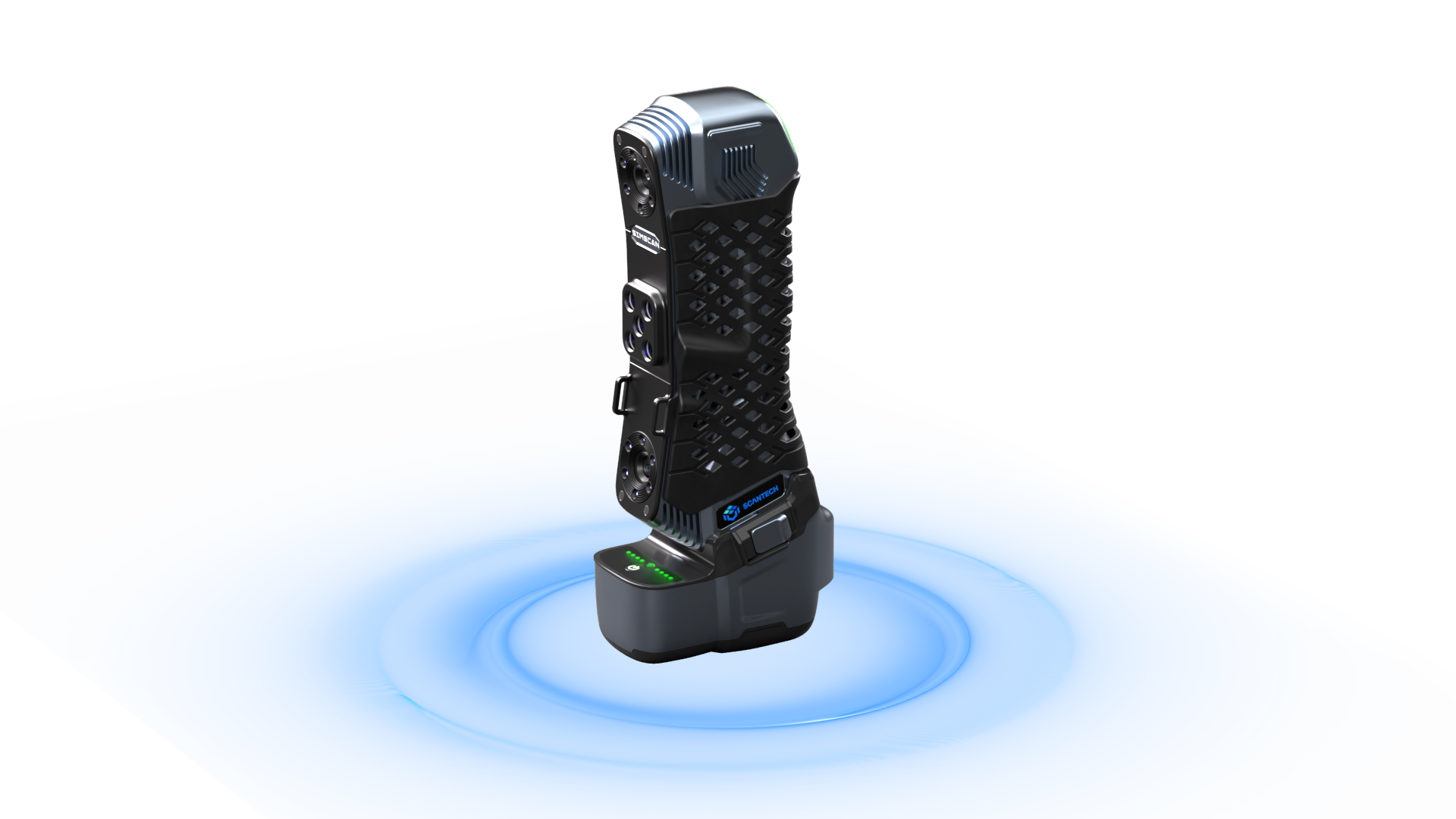

SCANTECH KSCAN-X

Take On the Biggest Jobs with Confidence

Portable laser scanning redefined with wide-view precision and seamless mobility.

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Large-View Laser Scanning Made Simple

Why Choose KSCAN-X?

Real-time phone screen viewing and operation

High-precision results for both large-scale and detailed measurements

Dual power cycle for uninterrupted operation

Short-distance camera design + Deep hole scanning

Stable and high-speed data transfer

Carry Power, Not Weight.

Portable & Powerful

Designed to fit in your hand, you can scan for long periods of time without fatigue and the compact form makes it ideal for travel – the entire case can fit into a carry-on bag with room to spare.

No Surface Left Behind

Scan difficult surfaces, deep holes, and fine details using bespoke scanning modes. Grid pattern is ideal for larger areas, while hyperfine mode coaxes out maximum detail, and single line mode helps scan into deep holes & recessed areas.

Built to Last

The robust metal case construction place it among the most durable scanners ever made and a wide operating temperature range broadens potential environments & applications.

See the Invisible

The KSCAN-X is perfect for large and challenging applications requiring high detail. With .075mm scanning accuracy, the KSCAN-X can scan large parts quickly.

KSCAN-X In Action

Precision Engineering Meets Portability

Watch the KSCAN-X capture large and challenging surfaces effortlessly—all while streaming data wirelessly in real-time for unrestricted movement around objects.

Key Features & Benefits

Scan complex and difficult surfaces using blue-laser technology and adjustable exposure that normally

would require preparation to capture.

0.1mm Feature Resolution

Create dense point-clouds and produce high-resolution mesh files for your large assemblies. With a resolution up to 0.1mm, small features like markings, text, and edges can be displayed clearly on the output file.

ISO and VDI/VDE-Certified

Certified for advanced metrology, create inspection reports reliably and repeatability, using the data

gathered. ISO17025 accreditation based on JJF1951 specification, VDI/VDE 2634 Part 3 Standard.

Blue-Laser Scanning with Multiple Capture Modes

Scan complex and difficult surfaces using blue-laser technology and adjustable exposure that normally would require preparation to capture. With two scanning modes, you can capture large areas of data with Grid pattern and then switch to Single Line for deep hole measurements.

Consistent Tracking and Accuracy

Using a target-based tracking system and up to 180 FPS capture speed, the KSCAN-X can maintain tracking with reduced amounts of targets needed for standard field-of-view scanners — allowing an operator of any skill to confidently use the scanner and capture all details of the object.

Ergonomic Design and On-Screen Information Display

Lightweight and comfortable grips allow you to hold the scanner and different angles without adding strain to users. And an onscreen display providing information on total data captured, scanning speed,

and resolution makes it easy to adjust settings without needing to be near a computer for feedback.

Larger Field of View

A standoff distance of 2.5 meters and field of view up to 1.8×2.6 meters allows the KSCAN-X to scan larger-sized objects quickly and see several targets at once to maintain tracking during the scanning

process.

Wireless Setup Capabilities

Able to utilize wireless USB’s to connect to computers remotely and send the scanner data to it for processing. Reducing the pain managing cords and limiting your ability to move around large parts quickly.

Technical Specifications

|

Specification

|

Value

|

|---|---|

|

Laser Source

|

Blue Laser – Class II Eye Safe

|

|

3D Point Accuracy

|

Up to 0.1mm

|

|

Scanning Accuracy

|

0.03mm with medium distance scanning. 0.075mm with large distance scanning.

|

|

Volumetric Accuracy

|

0.075mm + 0.01mm/m

|

|

Object Size

|

Medium-Large

|

|

Field of View

|

2600 x 1800 mm

|

|

Depth of Field

|

2500 mm

|

|

Scanning Speed

|

180 FPS

|

|

Tracking Method

|

Target-Based

|

|

Operating Environment

|

-10 degree C to 40 degree C. Fanless Device suitable for workshops

|

|

Certifications

|

ISO 17025 – based on VDI/VDE 2634, JJF 1951 specification

|

Frequently Asked Questions

While the scanner does require targets to maintain tracking – it doesn’t always have to be on the part.

As long as enough targets are within view on or around the part the scanner will continue to track its

position and capture data. With the KSCAN-X you can utilize 12mm targets and farther distances

between them compared to other hand-held laser devices.

It is possible, the resolution of the data can be captured up to 0.1mm which is suitable for smaller features on small parts. The different scanning methods and distances allow you to find a suitable setup

to capture smaller parts.

With customizable command buttons, the device will switch the laser grid between the two scanning modes with the scanners main buttons. The Grid Line Mode captures large amounts of data fast and a Single Line mode to capture deeper into pockets or thin-edges.

Due to the device using a Blue-Laser the KSCAN-X can scan shiny, dark, or pocketed surfaces easier.

These normally would require applying a dulling or opaque spray to properly capture. It also doesn’t require any re-calibration to switch between the different surfaces.

Yes, target-based laser scanning is excellent at capturing simple sheet metal surfaces with a high level of accuracy. With the multiple scanning modes thin edges can be captured and then aligned with other

scans using targets on the part or matching geometry.

Excellence Beyond Hardware

Technology is powerful. Partnership makes it transformative. With Hawk Ridge Systems, you get both—cutting-edge scanning capability backed by North America’s premier engineering solutions team, dedicated to turning your investment into remarkable results.

Expert Support

Access our dedicated team of 3D scanning specialists

Try Before You Buy

Test SIMSCAN-E on your actual parts with customized demonstrations

Comprehensive Training

Get your team operational quickly with personalized onboarding

Seamless Integration

Connect SIMSCAN-E to your existing CAD, CAM, and inspection workflows

SCANTECH

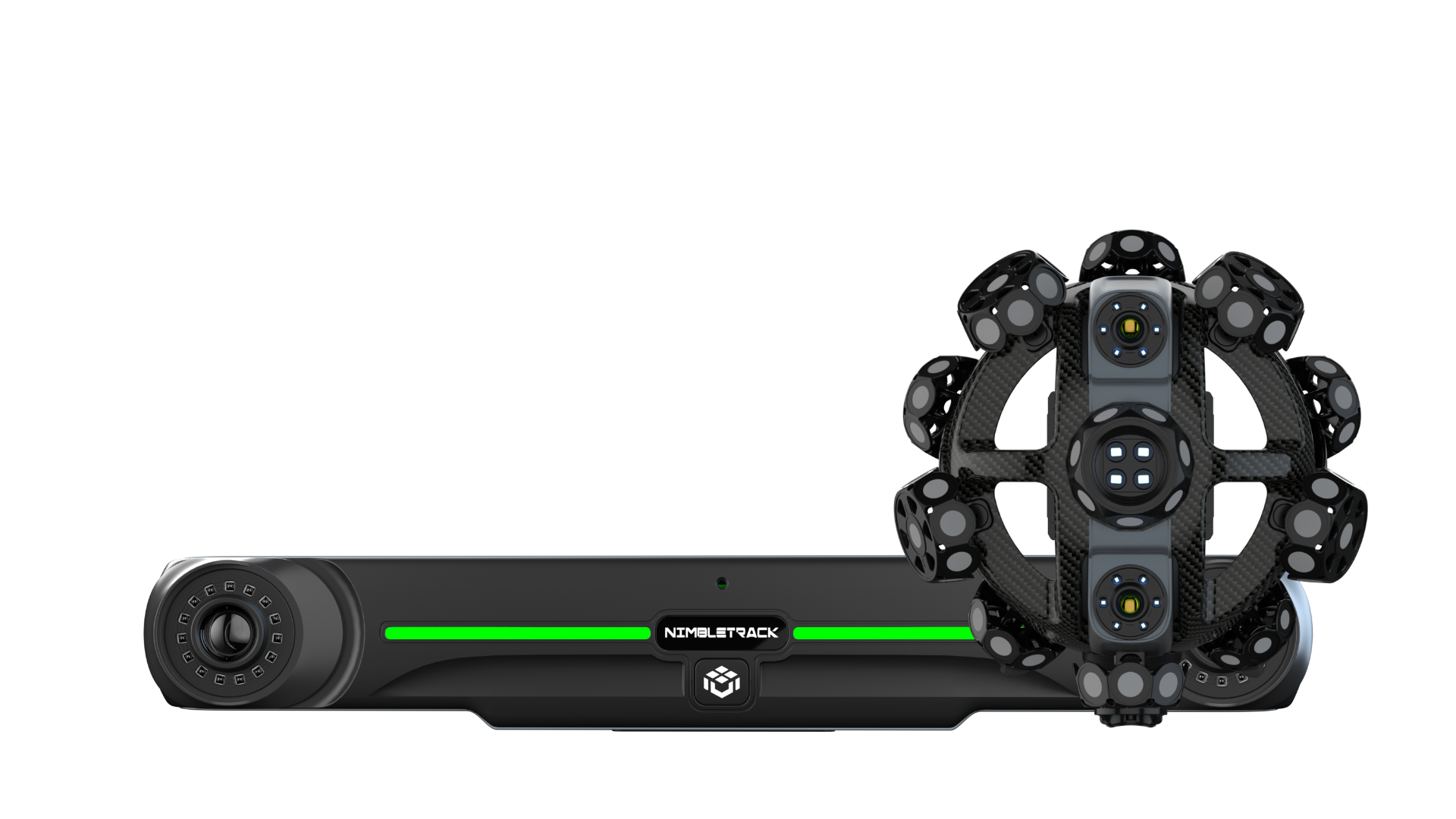

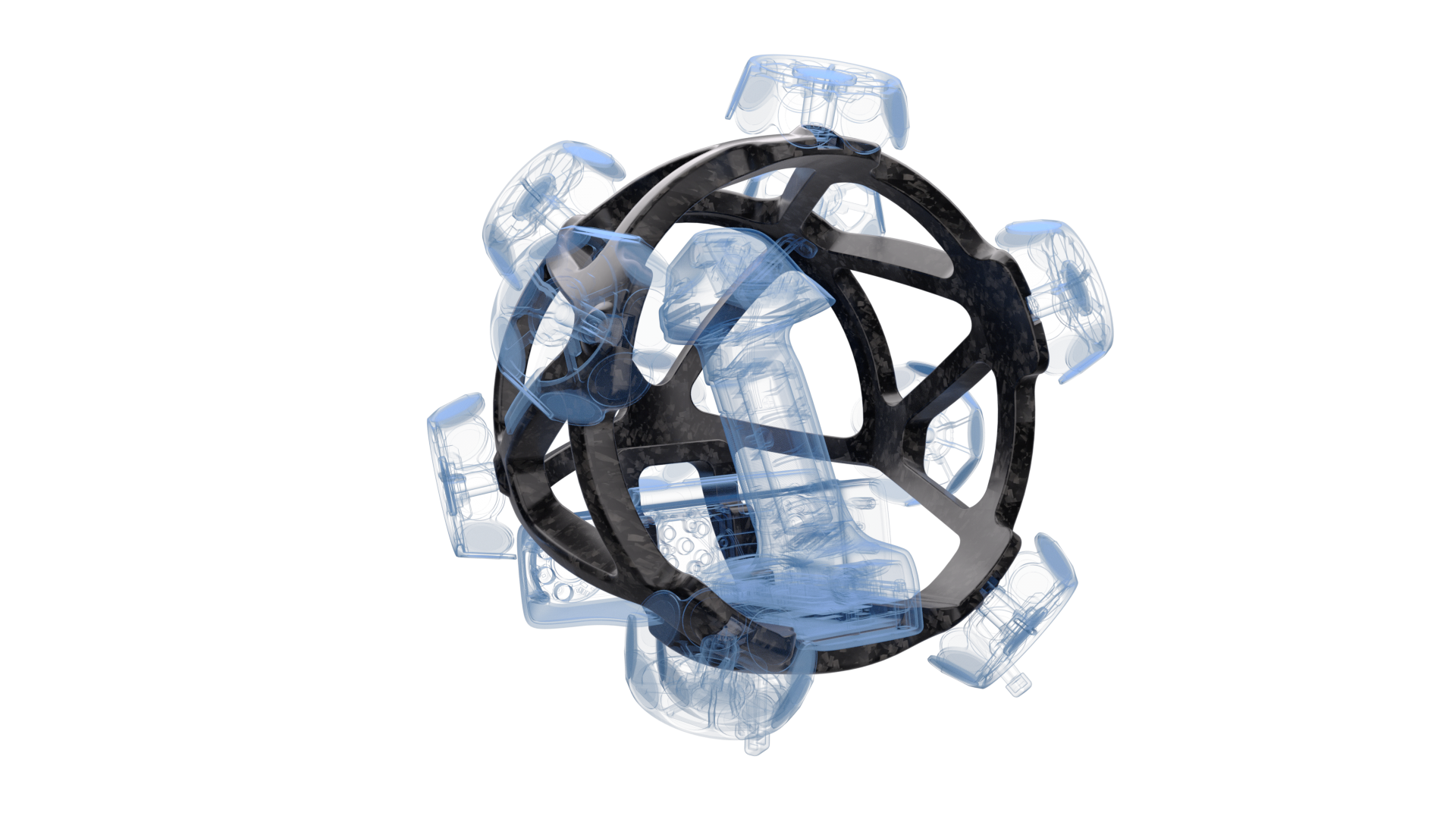

ScanTech: NimbleTrack

Learn More

ScanTech: TrackScan Sharp S

Learn More