CAMWorks is an easy-to use tool to check your toolpath for several problems such as

collisions, gouging, or under-machining. Proper use of the Toolpath

Simulation tool should be incorporated into every CAMWorks workflow. One

thing you may not know is that in CAMWorks 2014 and later you can start the

simulation from a work-in-process rather than from the raw stock. This is

extremely useful for simulating operations that depend on previous

operations to avoid a crash.

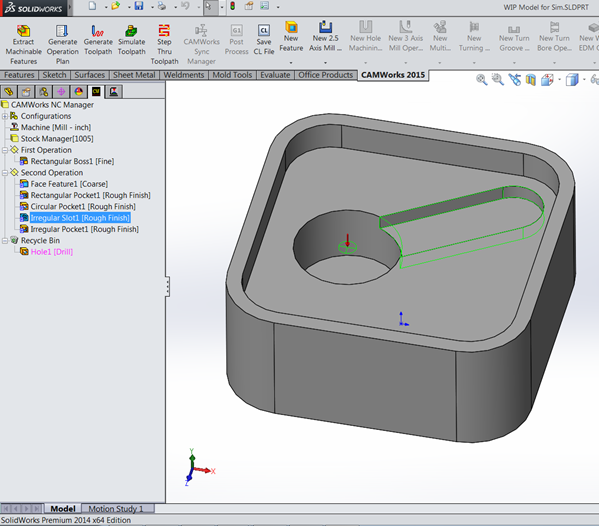

Let’s use a simple part with a few nested pockets as an example:

The highlighted slot feature is going to be machined after the rectangular and

circular pockets have already been cut. That allows the end mills for the slot

to safely rapid to depth in the existing pockets and enter the slot from the

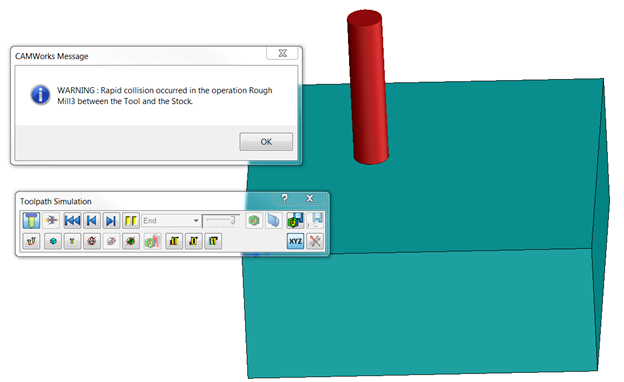

side rather than having to ramp or spiral to depth. When I run the

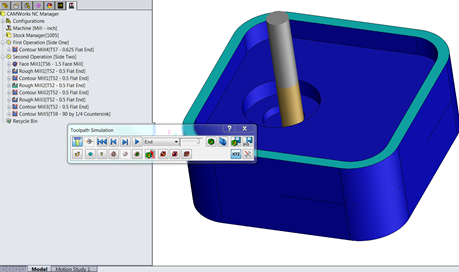

Toolpath Simulation the default behavior is to start the

simulation from the raw stock. This means that I have to simulate all of the

previous operations first just so I can see what the part will look like when

we start to machine the slot. If I don’t, then CAMWorks will think that my

rapid entry move will cause a crash:

So here is the trick: Just hold down [shift]on your keyboard when you invoke

the Simulate Toolpath command (version 2014 or newer). Now,

CAMWorks presents you with a dialogue asking what operations you want to be

simulated in the background for the Work-in-Process model. This command works

no matter where you invoke the simulation from, and it allows you to run

operations from previous setups as well.

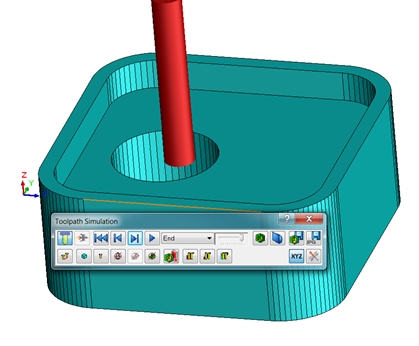

Once you select the operations for the “WIP” model and hit

OK, CAMWorks will simulate those selected operations in the

background much quicker than you having to sit through the simulation (note:

this can still take a few minutes for 3+ axis toolpaths, but it’s still

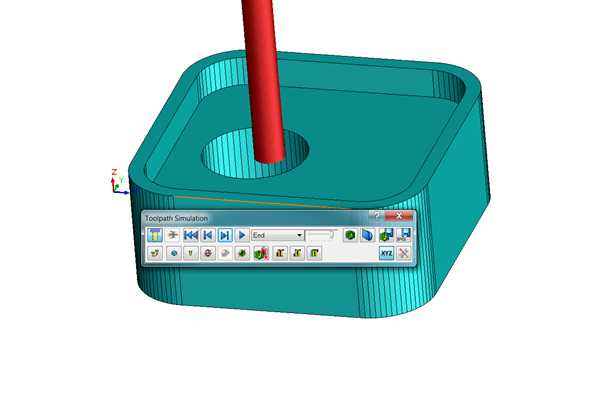

faster). Now, the “stock” that I am presented with for the simulation has

several cuts already taken out of it and just as predicted, my rapid entry

comes down safely in the space created by the previous operations:

This trick is particularly useful if there is an operation or two that you

need to simulate several times while making minor adjustments to the operation

parameters. In fact, once you get a hang of it you might find yourself

instinctively holding down [shift] every time you simulate a toolpath.

I hope you found this helpful. For more content like this please subscribe to

our blog and

YouTube channel. Happy machining!