When designing sheet metal parts, it’s very common to have an asymmetric part

that requires an exact opposite hand (mirrored) version. SOLIDWORKS has always

had a great part mirroring function that accomplished this in no time,

eliminating the need to completely create the new part from scratch. However,

if the part was made with Sheet Metal features, the manufacturing information

was not transferred to the mirrored part. This information is critical when

documenting the mirrored part on a production drawing. Introduced in

SOLIDWORKS 2015, when creating mirrored versions of sheet metal parts it is

now possible to transfer the sheet metal and flat pattern information from the

original part to the mirrored part, saving you a huge amount of time during

the drafting phase.

The manufacturing information that can be transferred to mirrored sheet metal

components includes:

- Flat pattern geometry • Bend lines

-

Fixed face •

Bend parameters -

Grain direction • Sketch

transformations -

Faces to exclude • Forming

tool information

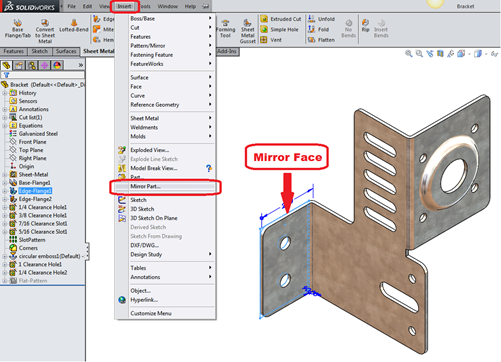

Let’s take a look at the process to see how this is done. To create our

mirrored part,we select the mirror face, then click

Insert > Mirror Part.

So far, so good. Nothing new to the workflow yet, but now here’s where things

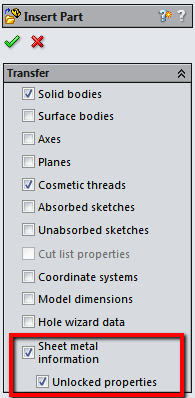

get interesting! In the PropertyManager, under Transfer,

select:

Sheet metal information: Transfers the sheet metal and flat

pattern information from the original part to the mirrored part, such as fixed

face, grain direction, bend lines, and bounding box.

Unlocked properties: This option allows you to edit the sheet

metal definition in the mirrored part, which will update the cut list

properties. This applies only to new feature properties, not the imported

mirrored body.

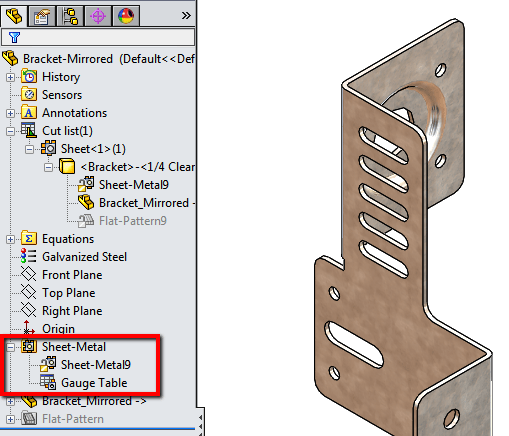

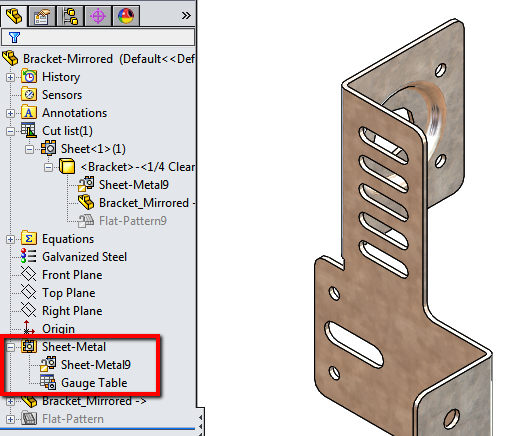

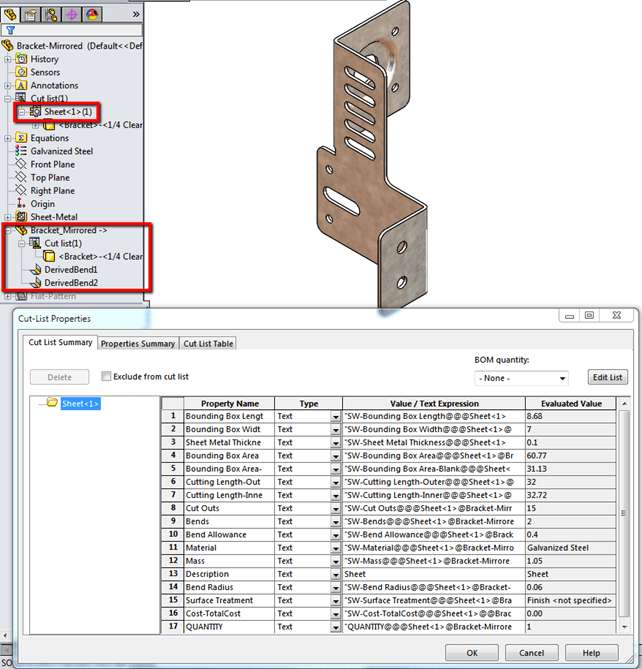

Now complete the operation by clicking the green check and let’s see what kind

of goodies came over into our new, mirrored part. The new part retains the

sheet metal information from the original part. If we expand the

FeatureManager, we can access all of the transferred properties and

information. First, in the “Sheet-Metal” folder, we can see that we have the

Sheet-Metal feature, which is editable (via RMB or Context Toolbar) because we

unlocked the properties when we created the part. If we needed to change out

the Gauge Table, thickness and bend parameters, and Auto-Relief settings,

that’s now possible.

Next, the Mirrored Part feature contains Cut List and bend information. The

Cut List properties are available. Note: if you RMB on the body feature in

this folder and select Edit Definition, you are taken back to the Transfer

property manager in case you need to include or exclude certain things from

your model.

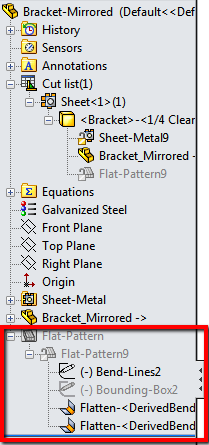

And lastly, the “Flat-Pattern” folder contains the flat pattern information.

You can edit the Flat-Pattern feature to change things like the Fixed Face,

Corner Treatments, Grain Direction, and Faces to Exclude. The Bend Lines and

Bounding Box sketches are also contained here, in addition to the Flattened

Bends. Just like a native sheet metal part!

All of this information in the mirrored part makes the drafting side of this

design much, much easier. The information for Bend tables, Cut Lists, Flat

Patterns, etc. are all contained in the part and can be used on your

production drawings to fully detail the design in a much more automated way

without having to recreate things that were already present in the original

part.