Trim Surface, Split, and Split Line – these three powerful SOLIDWORKS commands belong in every surfacing user’s utility belt, but learning when to use each and the (often subtle) differences between them can be a challenge. In this article, we’ll identify the unique functions of these commands and take a look at some proper use cases for each. While Split and Split Line are also applicable to solid bodies, this article examines them in the context of surface modeling. Each command can use a mix of plane, surface, face, sketch, and curve selections, and all three were used in the design of this glass bottle, shown below:

Figure 1 – Finished Bottle Design

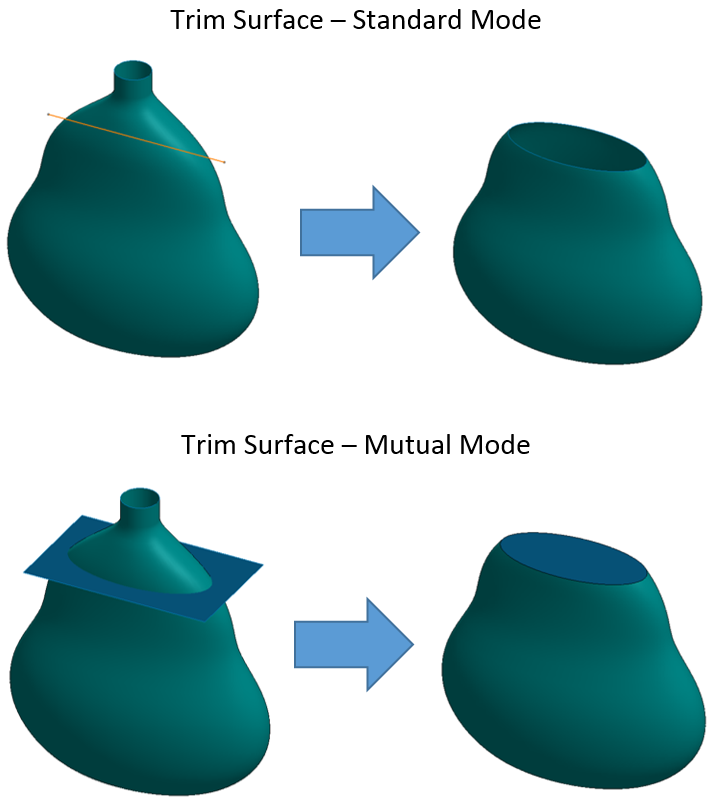

TRIM SURFACE: Primarily used to cut away material from a surface, and provides two modes: Standard and Mutual. In Standard mode, a single selection is defined as a Trim Tool, and target surfaces are trimmed accordingly. In Mutual mode, multiple surfaces are trimmed with respect to each other. Examples of each mode are shown below.

TRIM SURFACE USE CASE: Trim Surface is the go-to tool for trimming surfaces and removing information, and is exceptionally easy to use. Additionally, the unique capabilities of Mutual mode make Trim Surface the most efficient (and sometimes only) tool to use when modifying multiple surfaces with respect to one another.

Figure 2 – Before and After Trim Surface in Standard and Mutual Modes

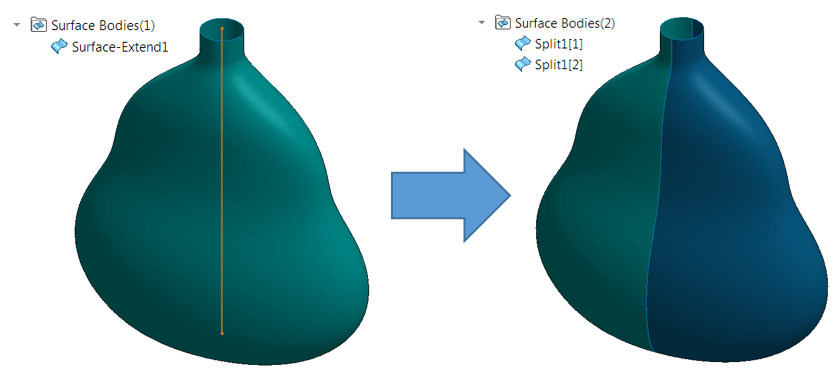

SPLIT: Similar in many ways to Trim Surface, but removal of surface material is optional. Split simply breaks the target surface into multiple bodies (unless options are specified). This preserves the original shape, while splitting the body and enabling the use of any commands that require body selections such as Thicken or Move/Copy Bodies. An example is shown below.

SPLIT USE CASE: Split should be used when the goal is to break a surface into multiple bodies without otherwise changing geometry. While Split can accomplish nearly everything that Trim Surface can, it lacks the flexibility of Mutual mode.

Figure 3 – Before and After Split Command (Sketch Highlighted in Orange)

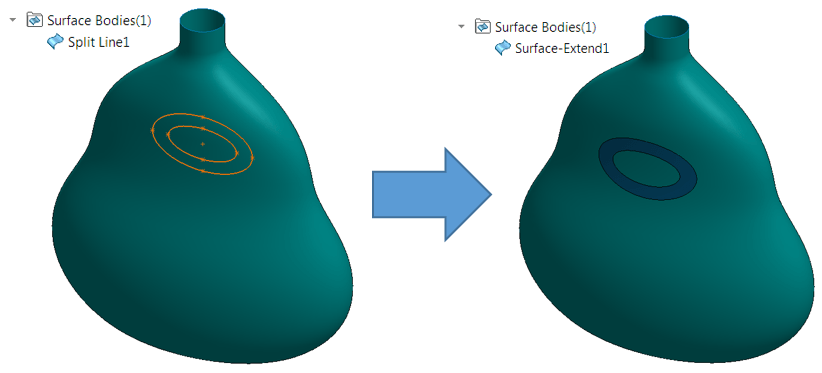

SPLIT LINE: Split Line is exceptionally useful for splitting faces without creating new surface bodies or trimming. In many cases, surface bodies must retain their original identity in order to preserve design intent and avoid feature errors, while the faces of the surface may need to be broken up. An example of Split Line is shown below.

SPLIT LINE USE CASE: To split faces of a surface body in order to apply appearances/decals, create new model edges, or leverage any other commands requiring face selections. While Split Line doesn’t trim or split surfaces, it’s an exceptionally valuable tool in both surface and solid modeling.

Figure 4 – Before and After Split Line Command (Sketch Highlighted in Orange)

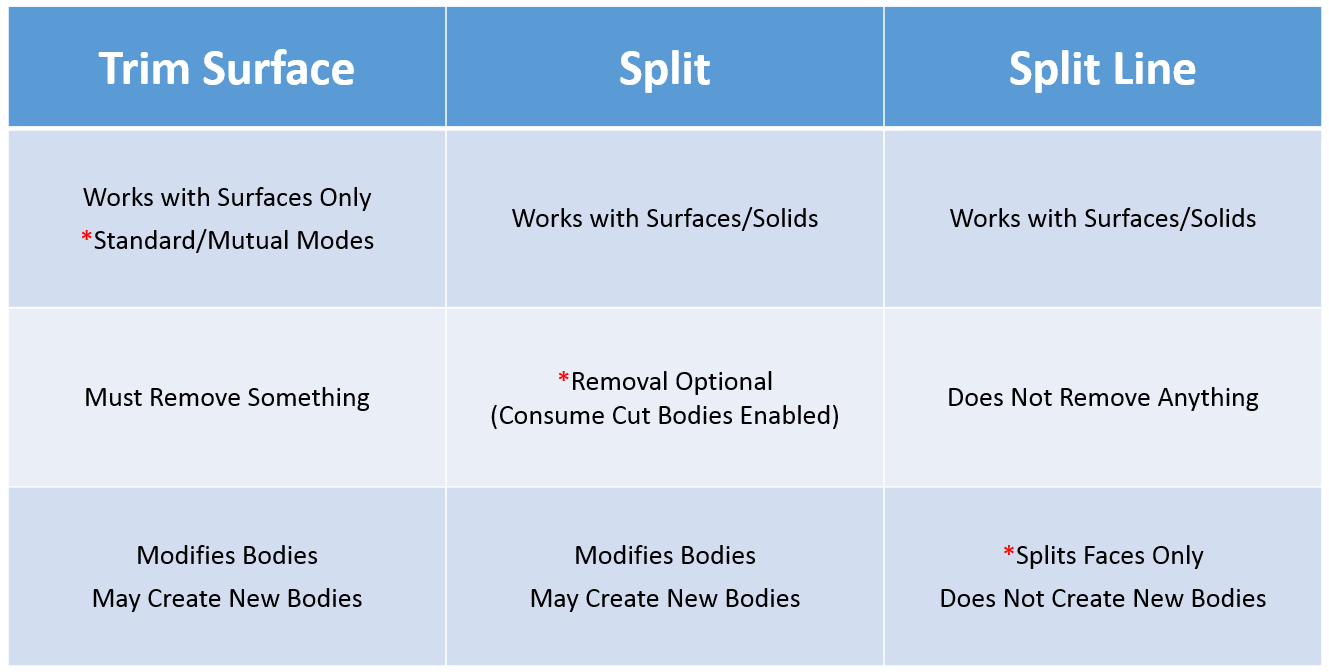

The following table summarizes all three tools discussed. The red asterisks represent the unique/defining feature or capability of each tool.

Figure 5 – Summary of Trim Surface, Split, and Split Line Tools

Do you have some other interesting use cases for these commands? Let us know in the comments!

For more information, request a SOLIDWORKS 3D CAD quote or contact us at Hawk Ridge Systems today. Thanks for reading!