If you own any version of SOLIDWORKS, you already own SimulationXpress, but will it be enough for your next simulation project? In this article, we’ll have a look at the key capabilities of the SimulationXpress tool, allowing you to decide if you’ll need the SOLIDWORKS Simulation Add-In or not.

SimulationXpress – What is it? Essentially, SimulationXpress is intended to be a first-pass stress analysis program that’s available in any version of SOLIDWORKS – Standard, Professional, or Premium. You’ll find it in the Evaluate tab of your CommandManager, and the tool itself runs directly out of the Task Pane. When using SimulationXpress for the first time, you’ll be prompted to activate it – this is a free and straightforward process, and the dialog will guide you through it.

Once activated, you’re ready to start simulating. As a free tool, there are naturally some limitations to SimulationXpress. Primarily, it should be noted that SimulationXpress is designed solely for static stress studies, so if your needs include fatigue, buckling, dynamic, or any other type of study, you’ll need to consider the Simulation Add-In (if you’re looking for flow simulation, however, you may have some luck with the available FloXpress tool found in the same area). The second major limitation is with respect to assemblies and multibody parts. SimulationXpress is only capable of simulating single parts, so if interactions and stresses between components are important to you, considering having a look at the Add-In.

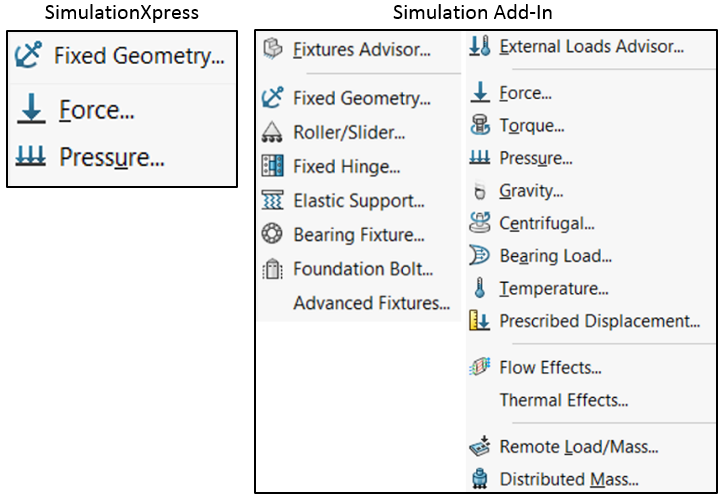

The SimulationXpress interface is a simple step-by-step wizard that allows you to apply fixtures, loads, and materials, and immediately begin simulating your part. You’ll find, however, that fixtures are limited to fixed faces, and loads can only be represented by forces and/or pressures. While this may be appropriate in many cases, if you require any advanced fixtures (elastic joints, rollers/sliders, etc.) or load conditions (torque, bearing loads, etc.), you’ll only find them in the Add-In. The graphic shown below lists the available fixture and load types available in each tool.

Before running your study, SimulationXpress also gives you the opportunity to modify the mesh that is used in the finite element analysis, but again, your control is limited. A simple slider is available to adjust the mesh element size, but the effects propagate globally and cannot be changed specifically in areas of interest. With the Add-In, mesh control can be used for precise results in critical areas, and cutting-edge algorithms are provided to generate curvature-based meshes, among others.

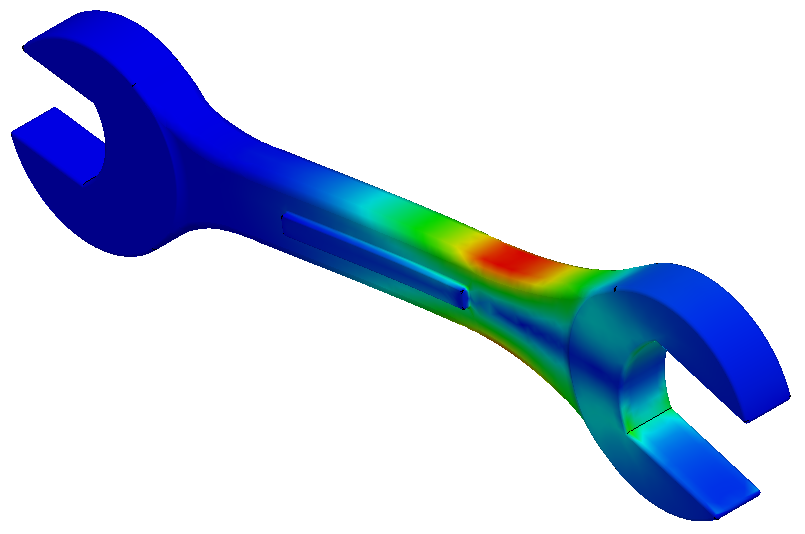

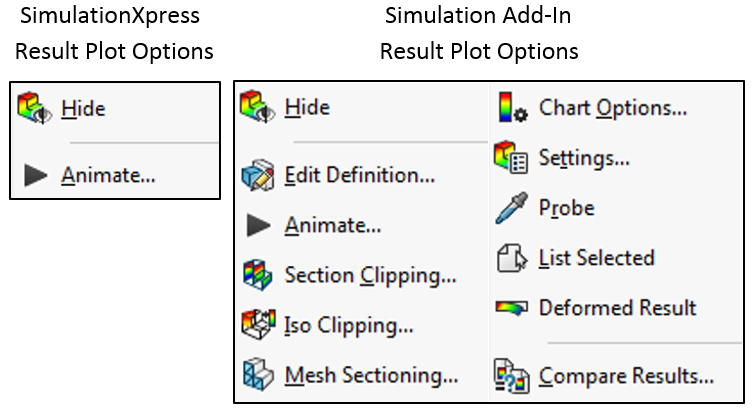

Finally, once the simulation is complete, you’re given the opportunity to view your results and export them as a report, either in Word document format or as an eDrawings file. Fully-colored plots for stress, displacement, deformation, and even factor of safety are available, but you won’t find many tools to help you interpret the data. For a quick comparison of the tools available for working with resulting simulation data, see the graphic below. Additionally, you can optimize your model from within SimulationXpress to improve your design, but you’ll face limitations once again in that only a single variable can be optimized at one time, and limited constraints and goals are available for optimization.

If you’ve made it this far and haven’t rolled your eyes yet, congratulations! You’re on your way to cost-free FEA with SimulationXpress. If you think you might need some additional simulation capabilities, or you’re interested in a wealth of extra tools and options for interpreting and manipulating simulation results, please consider having a look at the Simulation Add-In. Additionally, be on the lookout for a new article coming soon, where we break down the capabilities of each level of the Simulation Add-In and show you how you might even be able to run static studies on assemblies without spending a dime!

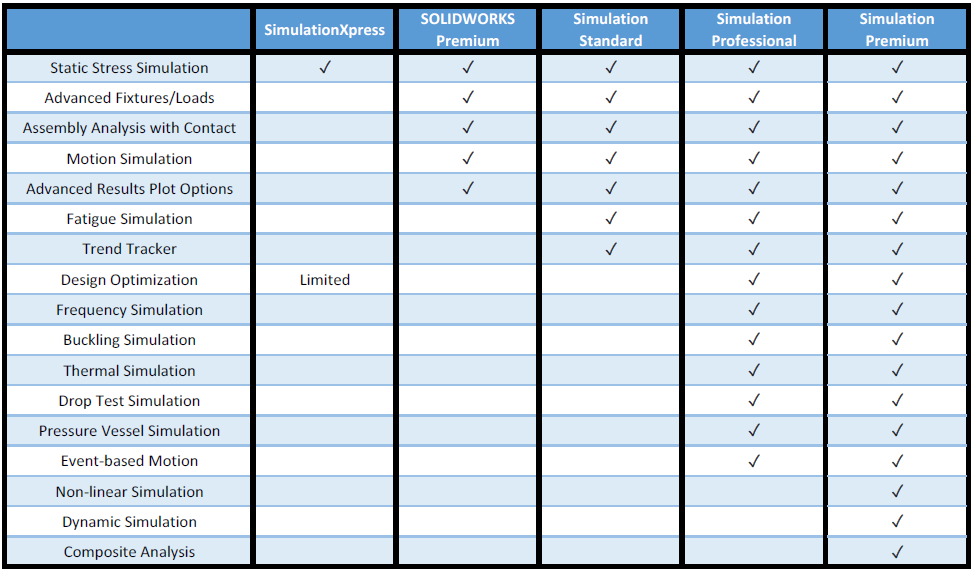

Below, you’ll find a matrix summarizing the different capabilities of SimulationXpress and the various levels of the Simulation Add-In. For more information, check out our YouTube channel, get a SimulationXpress quote or contact us at Hawk Ridge Systems today. Thanks for reading!