The mission statement of Hawk Ridge Systems has always been to discover and deliver world-class solutions for our customers. From digital design and simulation to full-scale manufacturing via 3D printing, each of our partners provides a comprehensive suite of tools that can help with many of the pain points involved in a product development cycle. Today, Hawk Ridge Systems is excited to announce a new partnership with Formlabs, an industry leader in both SLA (Stereolithography) and SLS (Selective Laser Sintering) Additive Manufacturing hardware.

In this blog post, we will delve into the Formlabs printers, materials, and software that are currently available.

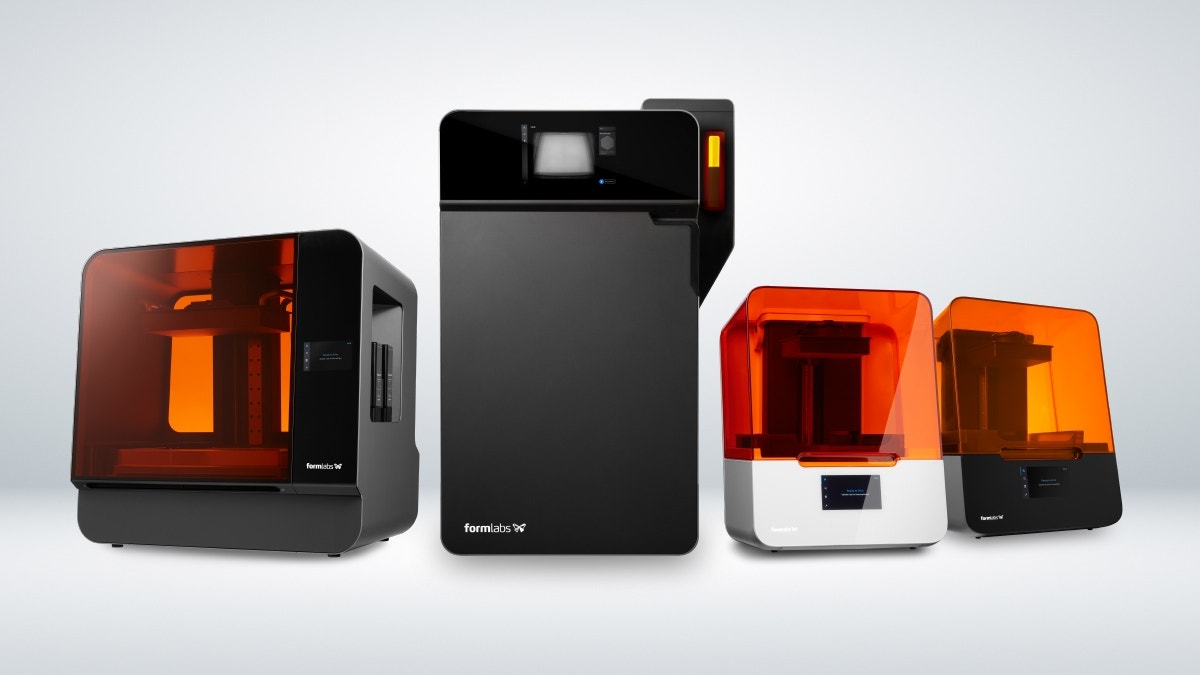

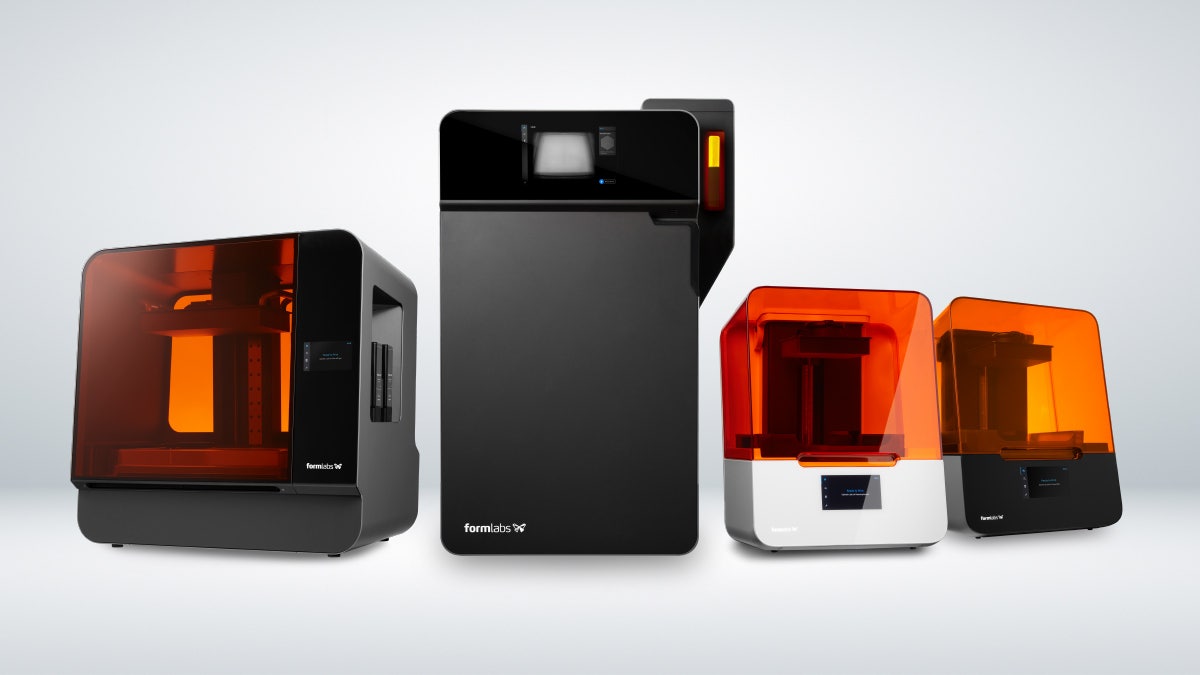

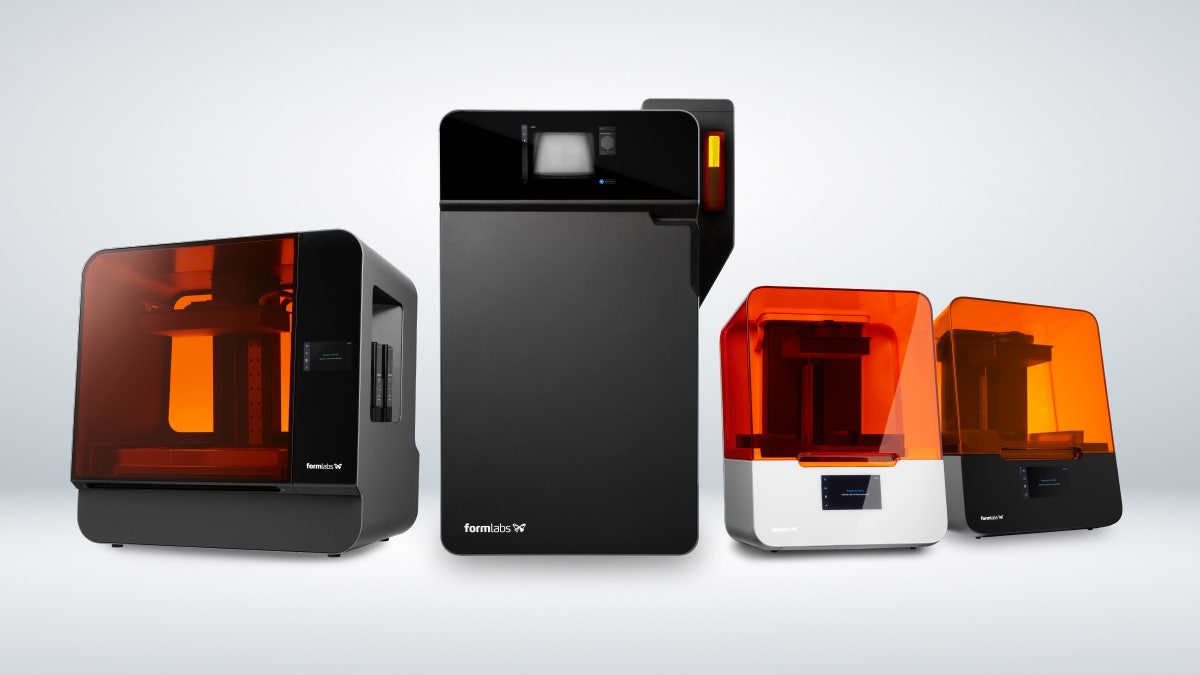

The Printers

Formlabs was founded in 2011 through a crowdfunding campaign for their first hardware, the Form 1. The goal for Form 1 was simple: to make high-precision SLA 3D printing more accessible and efficient. Crowdfunding for Form 1 was extremely successful and Formlabs has continued to enhance its platform by filling gaps and improving on its successes following the launch of Form 1.

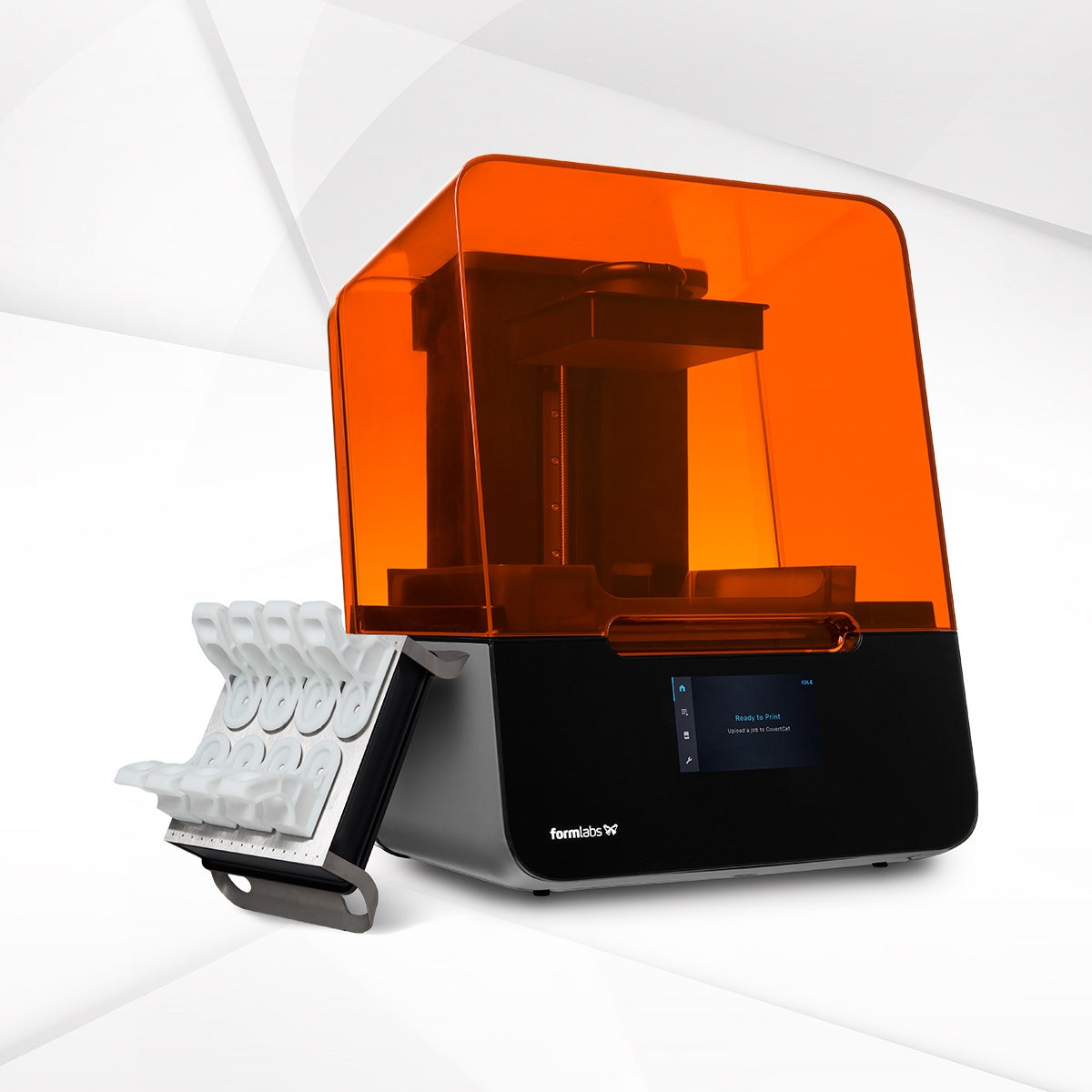

Today, Formlabs offers several different printers suitable for various stages of product development. The Form 3+ is the most popular SLA printer offered by Formlabs. Like its namesake, Form 3+ is an extremely affordable and cost-effective entry point into the world of SLA 3D printing. Ease of use also continues to be one of the primary drivers behind each printer created by Formlabs, meaning that even the initial setup of the machine is quick and efficient. Form 3+ is versatile and can be used to print parts for applications such as quick prototyping, tooling, and even molds or other manufacturing solutions. Formlabs SLA printers are known for the high level of detail they can achieve so functional models are a very common application for Form 3+ as well.

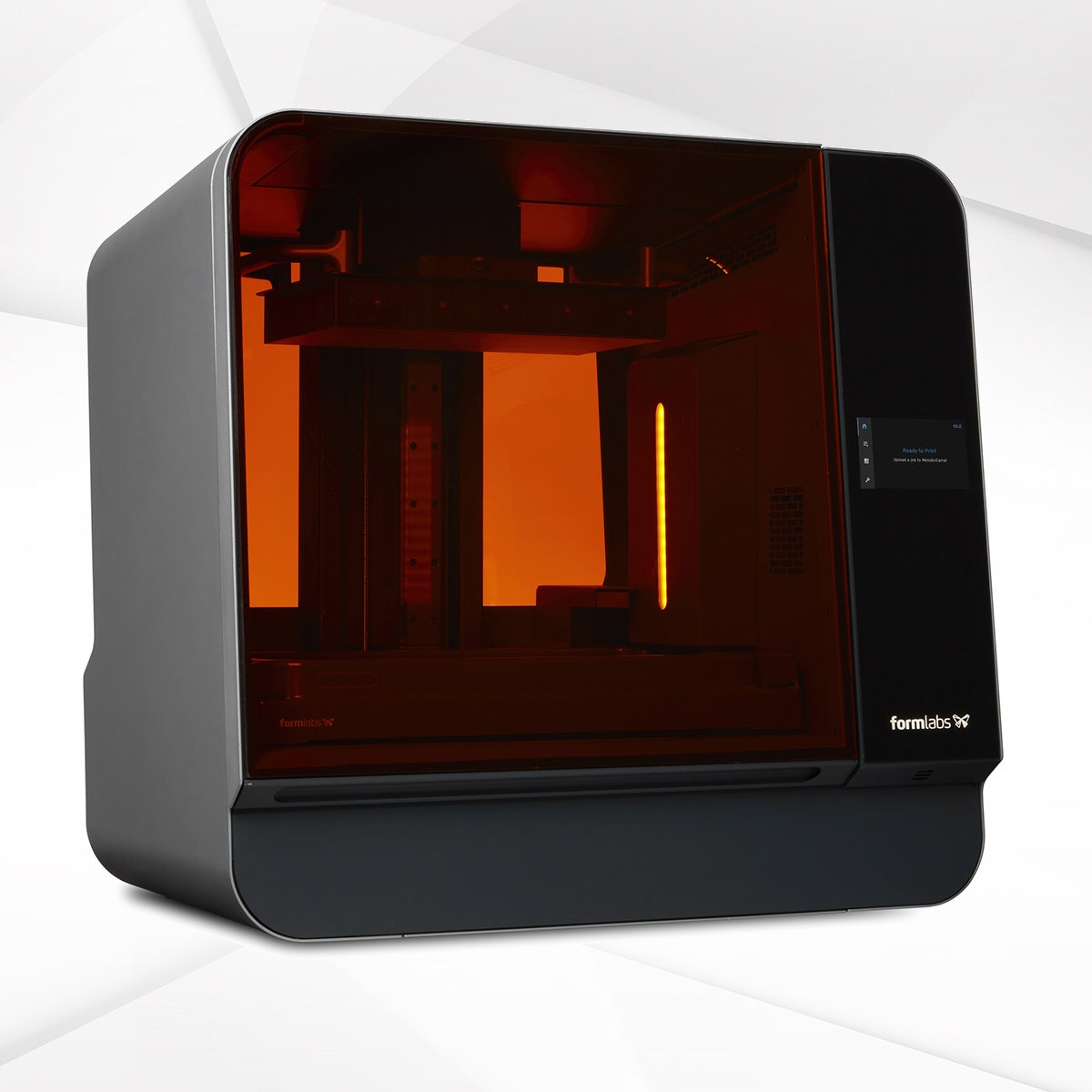

The Form 3L is a large format SLA printer that shares many capabilities with the Form 3+, but with an available print volume that is five times larger. Larger build volumes are often associated with the ability to print larger parts, however, the Form 3L also opens the door to printing more parts in a single run to assist with low-volume manufacturing. This machine also boasts dual 250mW laser assemblies, enabling users to print faster and cover the larger print volume more efficiently. Since the printers from Formlabs do not need to be monitored, users can more easily use the Form 3L to print larger parts or more parts during hours when they will not be in the office or on the shop floor.

Formlabs offers dedicated medical platforms with Form 3B+ and Form 3BL, which have the same print volumes as their non-medical versions discussed above. These two machines can use all SLA materials offered by Formlabs, including several biocompatible and sterilizable resins that are made in a Formlabs ISO 13485-certified facility. These printers are ideal for a variety of dental or skin contact applications where a custom fit or design is critical for patient success. Surgical or other implant planning models are also extremely common applications on the Form 3B models, which can help medical professionals be more prepared for complicated procedures.

Formlabs has taken extreme care to obtain additional healthcare certifications for their materials, ensuring that medical professionals can have the same level of confidence in their printed parts as other users have with the commercial line of systems.

As previously mentioned in this blog’s introduction, Formlabs has expanded its product line to include anSLS-based printing solution called the Fuse 1+. This machine is a powder-based 3D printer that was designed with the objectives of being affordable, reliable, and scalable. Since parts created by the Fuse 1+ are nested in a bed of powder, large numbers of parts can be nested into a single build without the need to consider supports. Any unused powder can be indefinitely recycled into future jobs until it is used to print actual parts, making it an ideal solution for reducing waste and individual part costs.

Paired with the Fuse 1+ is the Fuse Sift, which is a station used for cleaning print jobs and loading powder for follow-up prints. The Sift utilizes negative pressure to contain loose powder while parts are being cleaned, allowing the entire Formlabs SLS solution to operate in a wider range of environments with less strenuous facility requirements.

The Materials

Since their initial release of Form 1, Formlabs has continuously expanded its library of available materialsto provide consumers with the means to create parts that best suite their applications. At the time of writing this post, Formlabs offers over 30 different types of materials available across their SLA and SLS printer lines. While we love speaking about Additive Manufacturing materials, a list of more than 30 materials could be time-consuming to read through! So for this particular section, we will go over the categories that these available materials are generally grouped into and provide examples of materials ineach category.

The first and most common material category on the SLA line of Formlabs printers is General Purpose resins. These include materials such as Black, White, Grey, and Colored resins that are designed to create high-accuracy concepts or end-use parts. Draft resin is a specialized material dedicated to quick turnaround times for prototypes and can result in parts that are printed up to four times faster than other resins.

The next category of resins offered by Formlabs is Professional Grade resins. These are often specialty resins that can be selected based on the specific functional requirements of a part. As an example, Flexible 80A and Elastic 50A resins can be used if elastomeric parts are required. High Temperature, Electrostatic Discharge, and Ceramic resins are also an option for parts that have unique functionality. And if parts need strength, stiffness, or impact resistance to be successful, resins such as Tough 2000 andRigid 10k can be used.

With the capability of printing high-accuracy parts with very small features, SLA machines are commonly used in the jewelry industry. Formlabs have dedicated resins for jewelry via Castable Wax and High Temp resins, the latter of which can be used with vulcanized rubber molding.

Dedicated Medical and Dental resins such as BioMed Clear and Permanent Crown are also available on the Form 3B+ and Form 3BL which were discussed in our prior section. These are manufactured in an FDA-certified facility and can be sterilized or disinfected. Again, these are commonly used in short or long-term skin contact applications or for end-use medical equipment such as swabs. Additionally, dentalapplications are a great fit for resins that fall into this category as the quick turnaround time of Formlabs to produce custom fit molds that are unique to each individual.

Finally, in terms of materials, SLS Plastics can be used to print parts with varying properties on the Fuse 1+. The most common material used on this system is Nylon 12, which is a very popular thermoplastic amongst Formlabs customers as it can print complex parts with high detail while delivering good mechanical properties. If more strength is required, Nylon 11 Carbon Fiber can increase the performance of parts printed on the Fuse 1+ and is even used as an alternative for metal parts in some applications. Formlabs also recently announced TPU 90A, which will be the first elastomer available for printing on their SLS system. You can read more about the latest material in their announcement post!

The Software

In this final section, we’ll briefly cover the software offerings that are available from Formlabs. Unsurprisingly, we will start with the PreForm print preparation software, which covers all the printers and materials we have previously discussed. PreForm accepts files in both STL and OBJ format so this is aCAD agnostic tool as designs can typically be exported in one format or the other. Once your part is imported into PreForm, the software will automatically configure the orientation and required supports for your geometry. Print times, material usage, and other important stats are easily accessed via the PreForm UI, and any printing concerns are also automatically flagged. This tool also gives users the ability to manually configure supports and other print properties if they would like more control over how their part will print.

Formlabs also has other software tools available such as Dashboard and Fleet Control. These solutions can allow more precise management of multiple printers and open the door to increasing the productivity and active print time of their hardware.

Closing Thoughts

Thank you for joining us today in this partner announcement and technical overview of Formlabs! We are extremely happy to be joining Formlabs in their mission of reducing pain points in the product development cycle via the use of Additive Manufacturing. If you have any questions on the capabilities ofsolutions offered by Formlabs or would like to talk to one of our experts about a potential application, please feel free to contact us today.