SolidWorks Simulation training classes, which hopefully most readers out there using Simulation have had a chance to

attend. Not only do students learn valuable information from the “where’s that

button” category, it’s a chance to have a discussion about some mechanical and

FEA theory, and what Simulation settings will give you the best results (the

latter probably being a lot more interesting). An option that anybody who has

taken this class should be familiar with is the Draft Quality Mesh option

underneath the Create Mesh property manager. Enabling this checkbox switches the

mesh element type from the default high-quality tetrahedron to a simpler

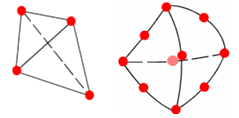

draft-quality version. The main difference between these two element types is

the number of nodes that are present; high quality tetrahedrons each have 10

nodes (one per corner and one in the middle of each side), whereas draft quality

has 4 nodes (at the corners only). This also means that a high-quality element

has more total degrees of freedom (DOF) than a draft version.

As expected, this means that high quality elements are more accurate, while

draft quality elements solve more quickly. However, a common misconception is

that high-quality elements are only more accurate because of these

extra nodes. In reality, the high-quality element is inherently more accurate

because the equations run inside the element are different; these equations are

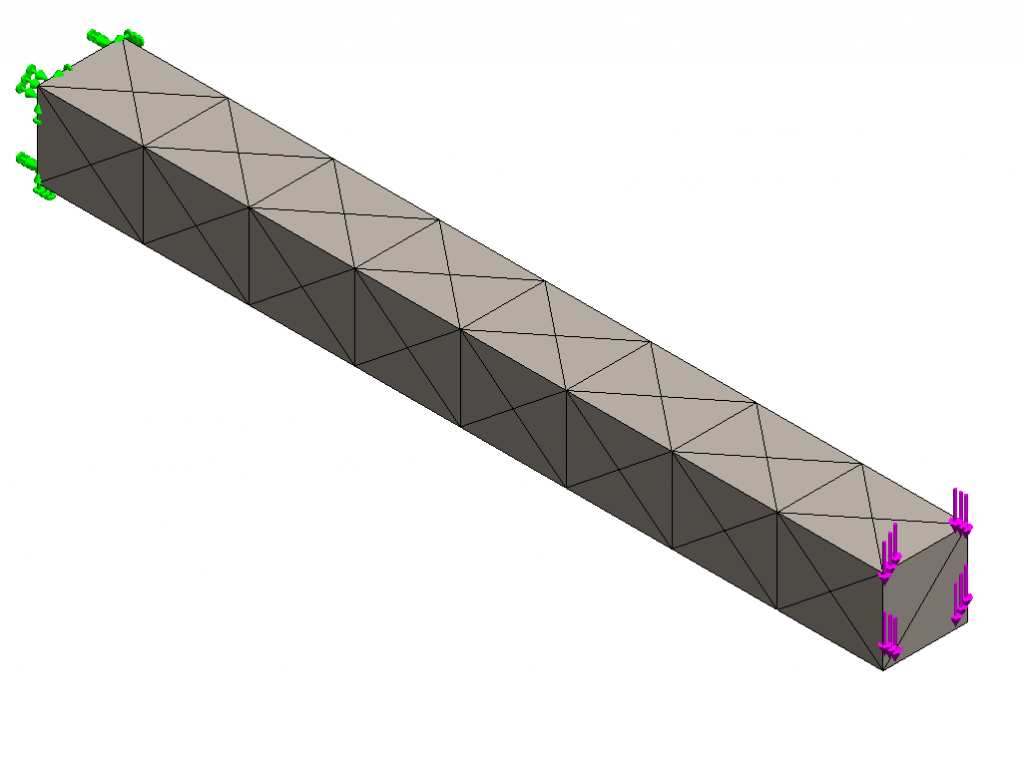

known as the shape functions. As an example, let’s look at a simple 10cmx10cm

square beam of AISI 304 steel, which is 1m in length, loaded with 10,000 N at

the end.

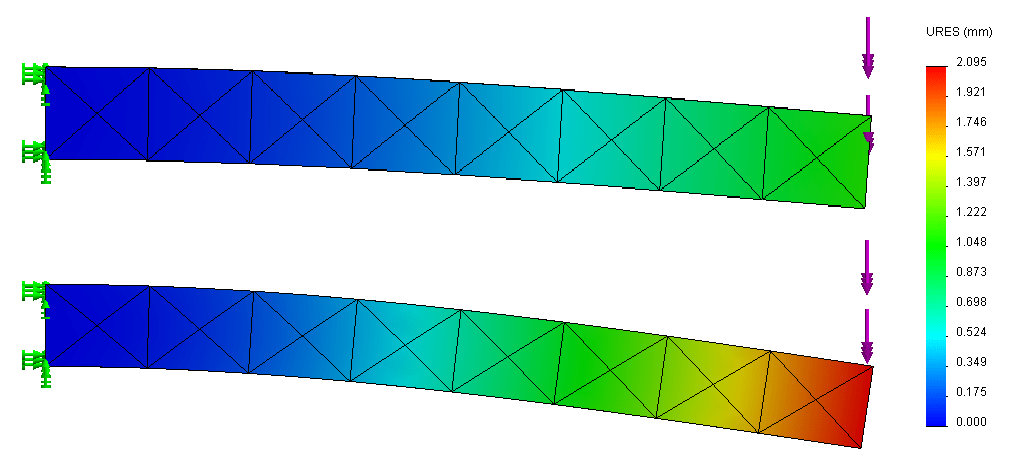

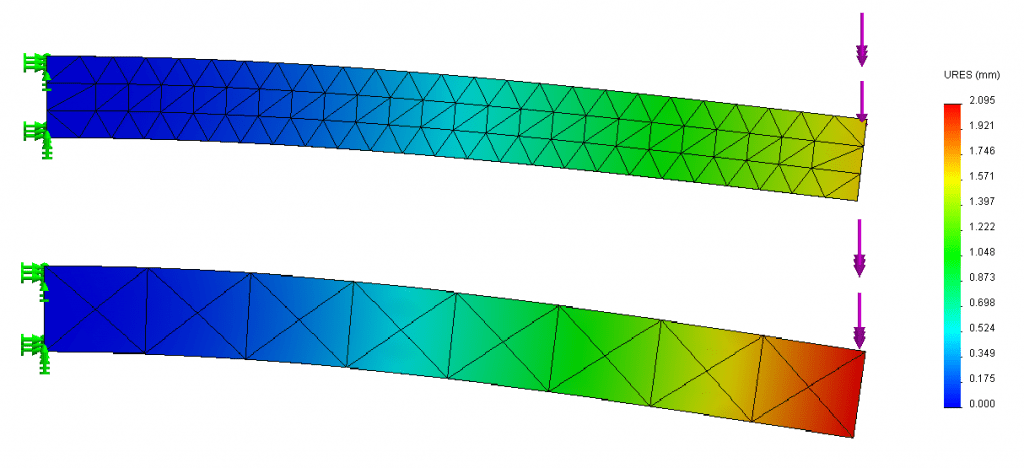

We’ll use a very coarse mesh for this model (0.1m) to highlight the differences

between running the study with the Draft Quality Mesh checkbox enabled (top) and

the default high-quality mesh (bottom).

a difference in accuracy as expected. The high quality elements show a maximum

displacement of about 2.1mm, whereas the draft quality is off by 50%, (showing

a maximum of 1mm). Now, we’re all well aware that using a finer mesh will

generally yield more accurate results in simulation due to the extra nodes,

and as we’ve discussed, the high quality mesh has more nodes than draft

quality. But, is this the whole story?

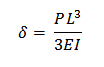

To get a better idea, we can refine the mesh in the draft quality version so

that the two meshes have a similar number of nodes (and also a similar number of

DOF). If the accuracy is related to the nodes only, we should see similar

results. This time, we’ll use an element size of 0.04m for the draft quality

mesh, which results in 404 nodes and 1170 DOF (compared to 401 and 1176 for the

high quality mesh).

Contrary to what you might expect, even after refining the draft quality mesh so

that it has the same number of DOF as the high-quality mesh, the results still

don’t match. The high quality element is still more accurate because it uses a

more advanced shape function than its poor simple cousin. We can confirm that

the high quality mesh is more accurate by doing a hand calculation for the

displacement using the beam equation derived from

Castigliano’s method:

… where P is the load, L is the beam’s length, E is the young’s modulus, and I

is the 2nd moment of area.

This pattern of consistently under-estimating displacements, and thus

over-estimating the stiffness of a structure, is a known drawback of a basic,

first-order tetrahedral mesh in the FEA world, and is particularly noticeable in

bending problems like this. Luckily, using the default high-quality version in

SolidWorks (also known elsewhere as a quadratic tetrahedron) does not exhibit

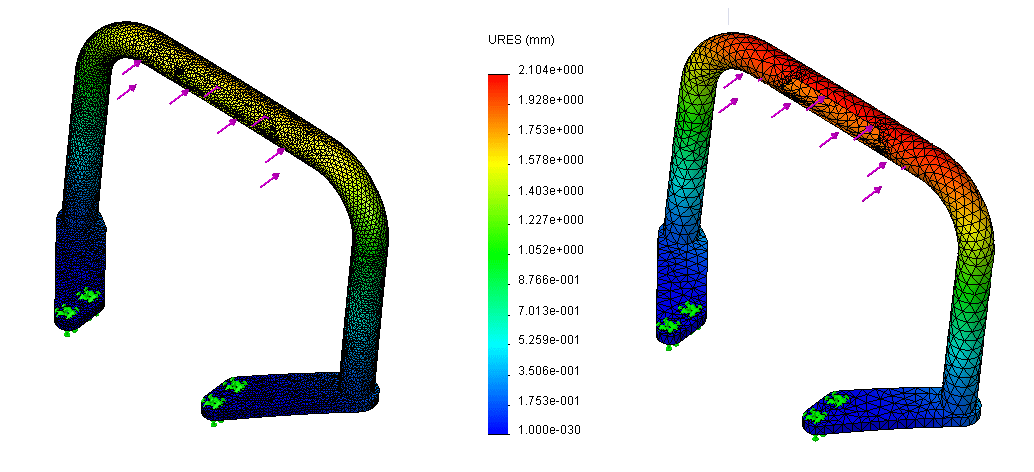

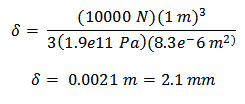

this issue. The effect can even be seen in real-world models, such as the handle

assembly below from a Holmatro Spreader rescue device. The draft quality mesh,

despite being more refined, still under-reports the displacement from this 100

lb load.

So, the moral of the story is this: the draft quality checkbox should be used

exactly like it’s named. Always set up your study and do a quicker “draft” run

with the Draft Quality Mesh checkbox on to verify your loads, fixtures, and

contact. Then, always switch back to the default high quality mesh for your

final results. You’ll be getting the right results and saving

precious CPU cycles for that Minesweeper window running in the background.