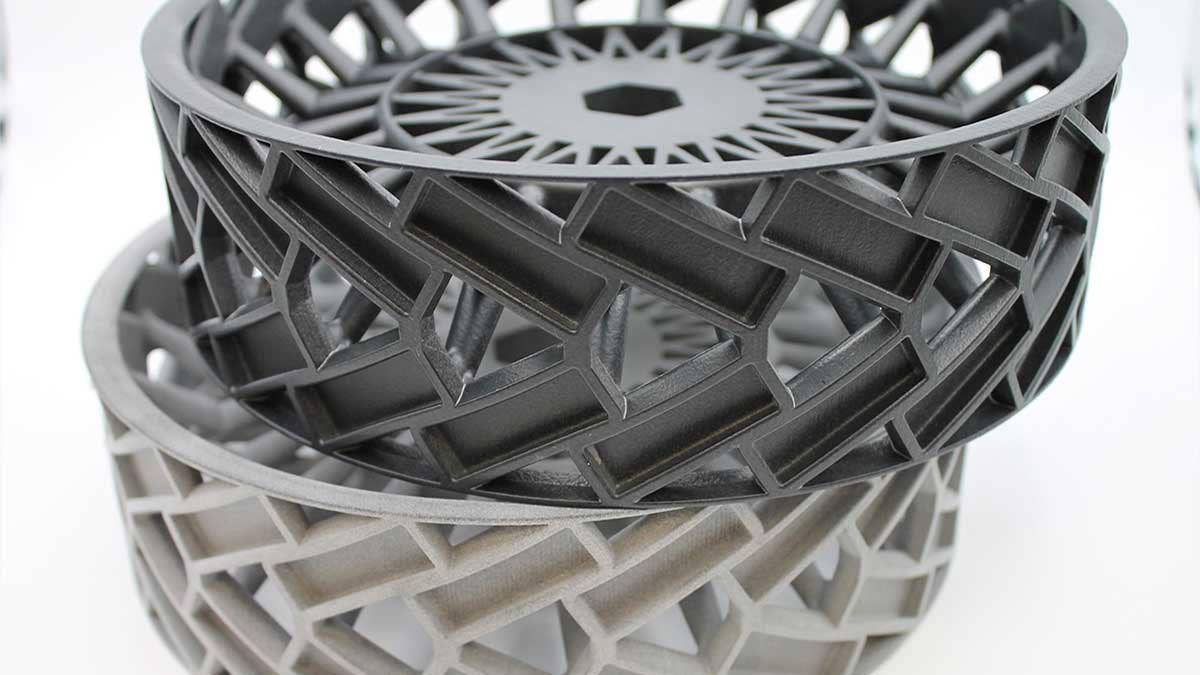

Do you want to take your 3D printed parts to the next level of quality and functionality? Post-processing your 3D printed parts with professional techniques is what it takes to achieve end-use strength and cosmetic finish for real world applications. Learn what can be achieved and how your parts can be improved to withstand the toughest environments, as well as gain an understanding of design methods that will better prepare your project for successful, and scalable post-processing.

One of our 3D printing application engineers teams up with additive service bureau Streamline 3D for an in-depth webinar to cover the ins and outs of professional post-processing techniques for 3D printed parts.

The session covers the following post-processing techniques using real world application examples:

• Vapor Smoothing

• Tumbling

• Dyeing

• Painting

• Electroplating

• Hydrographics

Watch Webinar Now

If you’d like to explore post-processing options for your business, be sure to check out Streamline 3D. As always, if you have any additive manufacturing questions for our experts, contact us at Hawk Ridge Systems today.