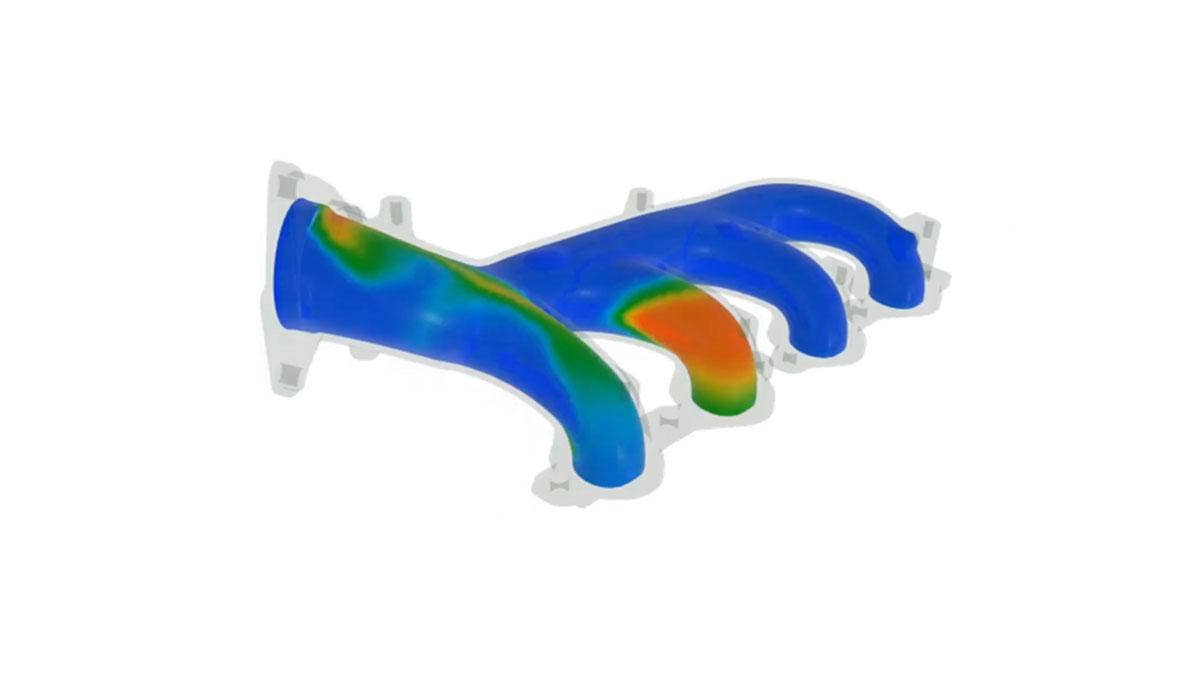

At Hawk Ridge Systems, we are passionate about showcasing analysis tools that can help engineers validate and improve the products they design in SOLIDWORKS, meeting a huge range of performance requirements for everything from static loading to sustained heat.

In the realm of fluid flow and thermal analysis, the tool of choice has long been SOLIDWORKS Flow Simulation, which lets users create and run true CFD analyses directly from the SOLIDWORKS environment. While the ease of use and CAD integration will continue to make Flow Simulation popular for years to come, SOLIDWORKS designers now have another choice for traditional Navier-Stokes based CFD utilizing the cloud-based 3DEXPERIENCE platform.

Discover SIMULIA Fluid Dynamics Engineer

SIMULIA Fluid Dynamics Engineer, as the role is known, allows users to upload their SOLIDWORKS models to 3DEXPERIENCE (or create them directly from web-based apps such as xDesign), and run the same types of fluid flow and heat transfer problems as in SOLIDWORKS Flow Simulation, with a few added benefits. While making use of this tool opens up some interesting new options for the physics of your simulation, such as the K-w turbulence model or accounting for surface tension in liquids, the real stars of the show are the cloud solving and results sharing capabilities enabled by the 3DEXPERIENCE platform.

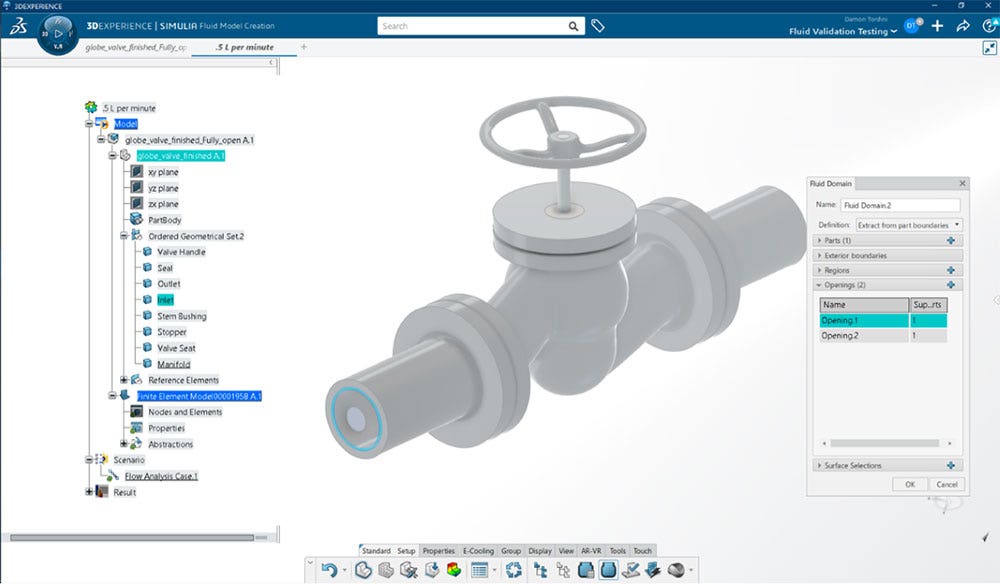

Once you have logged into the 3DEXPERIENCE platform, you can launch the Fluid Model Creation app to get started, which typically begins with the Fluid Domain creation tool. Just like in SOLIDWORKS Flow Simulation, Fluid Dynamics Engineer detects the fluid space inside a model, with the added benefit that inlets and outlets in the geometry (such as this globe valve) are detected automatically — no lid creation required.

Once the fluid space is defined we can assign a material from the 3DEXPERIENCE library (in this case water), and define some boundary conditions — here, a volume flow rate of 0.5 L/s.

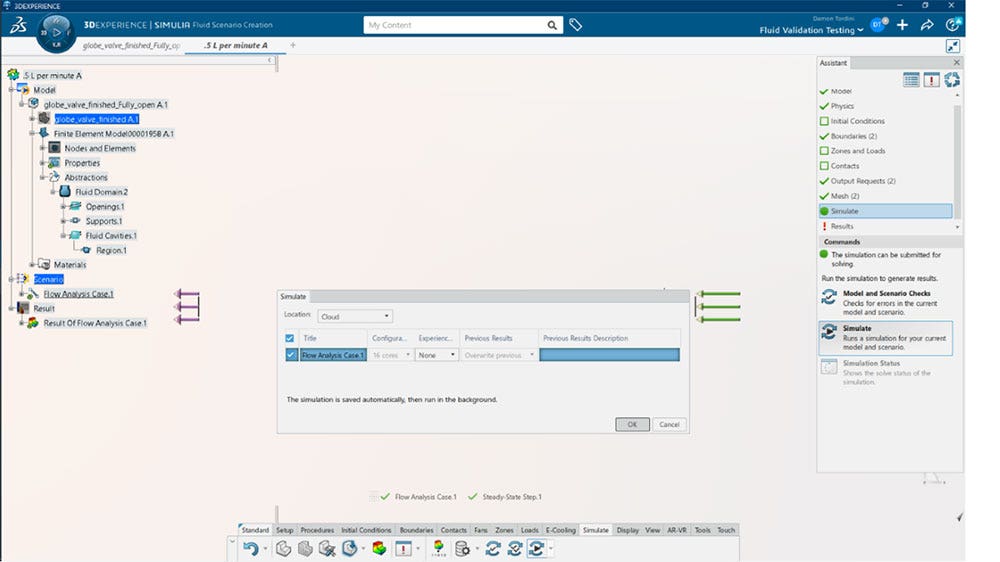

When it comes time to run the analysis, we can finally take advantage of the most significant advantage of this tool in the form of its cloud computing capabilities. Where SOLIDWORKS Flow Simulation has always been limited to the CPU hardware available on your desktop machine, Fluid Dynamics Engineer allows any job to be solved on the cloud with unlimited use of 16 processor cores.

This capability comes in handy when using the default settings of Fluid Dynamics Engineer’s hex-dominant mesher, which puts specific emphasis on accurately capturing the boundary layer of all surfaces in a solid model. Thankfully, engineers can make use of cloud compute credits to increase the number of CPU cores used in cloud computing to 144 or more, drastically improving performance.

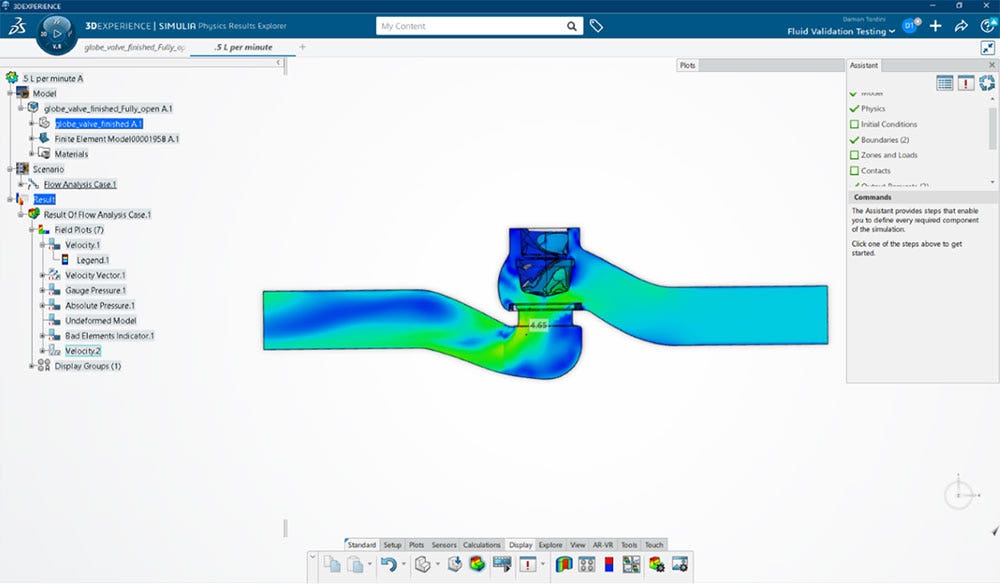

When the analysis is complete, you’ll be presented with a familiar set of results including velocity, pressure, density, and other user-defined parameters. Unlike in SOLIDWORKS Flow Simulation where individual types of plots must be separately created, Fluid Dynamics Engineer displays these results across the entire fluid volume by default, allowing you to cut or slide a section view at will, and switch between different results on the fly.

While comparing a design change isn’t quite as seamless as using Flow Simulation’s Parametric Study capability, we’re still able to follow the familiar process of changing features or dimensions in SOLIDWORKS, at which point we can hit the Update button from within Fluid Dynamics Engineer to retrieve the current version of the model and re-run the simulation. Best of all, these results are stored on the 3DEXPERIENCE platform, ready to be quickly shared with other members of the team without worrying about disk space or internet upload speeds.

Best of all, getting familiar with the 3DEXPERIENCE platform opens up users to a much wider universe of tools that includes everything from multi-physics analysis, to generative design, simulation of additive manufacturing, and more. Stay tuned to our blog for more examples of analysis in action, and contact us at Hawk Ridge Systems for any questions. Thanks for reading!