Parts printed with Markforged composite 3D printers exhibit incredible print quality, dimensional accuracy and excellent mechanical properties that allow them to be used in a wide variety of end-use applications. To achieve these results from the CFF process, however, it is critical that your plastic print material is kept free of moisture. In this article, you will learn all you need to know about troubleshooting and preventing wet material in your Markforged system.

Why Do Markforged Materials Material Get Wet?

Nylon, which is the primary component of Markforged’s Onyx, Onyx FR, Onyx ESD, and Nylon White materials, is very hygroscopic, which means that it readily absorbs water. Because of this, Markforged plastic materials will quickly absorb moisture when it is present in the environment in which they are stored.

Why Is It a Problem?

While this is usually not a problem for parts that have already been printed, this moisture ingression can cause several issues in the printing process. When the filament is melted in the nozzle during the printing process, the water that the filament absorbs will be heated rapidly and significantly. This causes the water droplets in the filament to expand as they turn into steam. As this steam expands, it creates bubbles in the material that is in the nozzle, which both forces material out of the nozzle and creates voids in the extruded material. This leads to parts that not only have an unacceptable appearance and surface finish, but that are also functionally compromised.

Signs That Your Material is Wet

When it comes to identifying wet material, there are several telltale features that will manifest themselves on your prints if your material is wet. If your material is wet enough to cause issues with the printing process, you will likely see multiple signs of wet material at once. Below are some of the most common signs that you are printing with wet material:

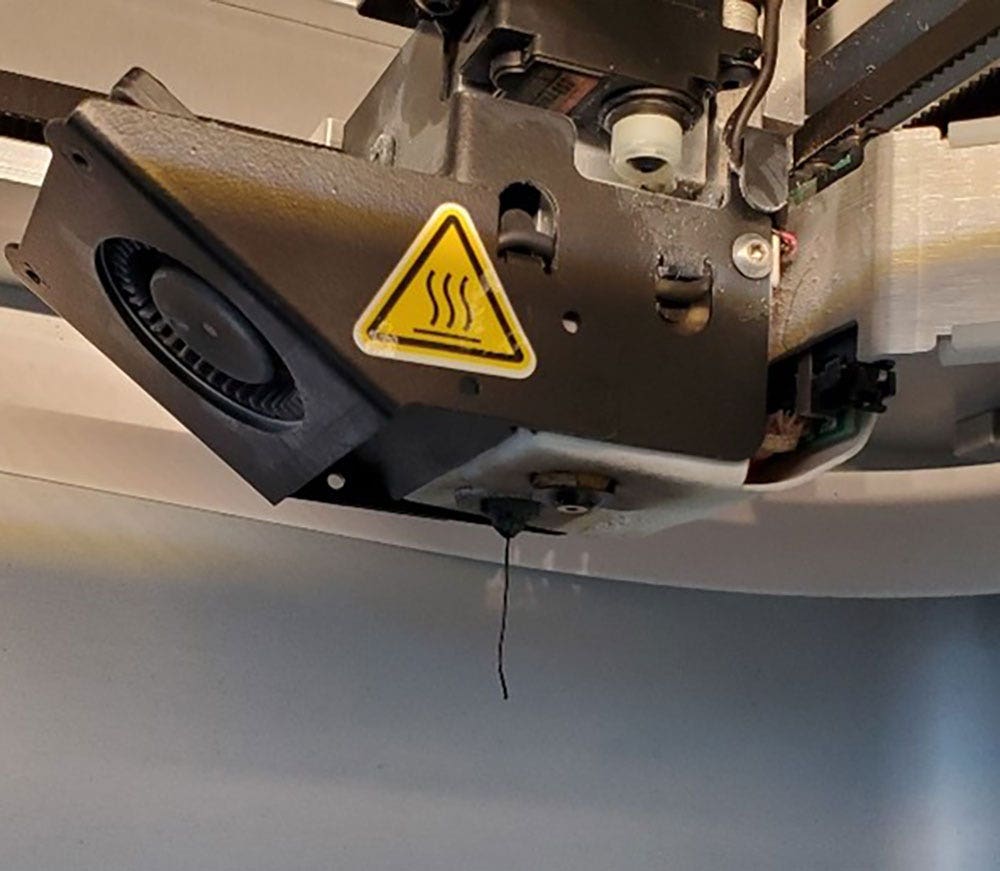

Nozzle Drip

As mentioned previously, when wet plastic material is melted in the nozzle, the water droplets expand as they turn to steam. This expansion forces material out of the nozzle, even if the printer is not currently extruding material. For this reason, if you are printing with wet material, you will notice that the nozzle “drips” material when it is not depositing plastic material and it is heated to printing temperatures. This manifests itself in a small amount of plastic slowly growing and hanging from the nozzle while it is hot.

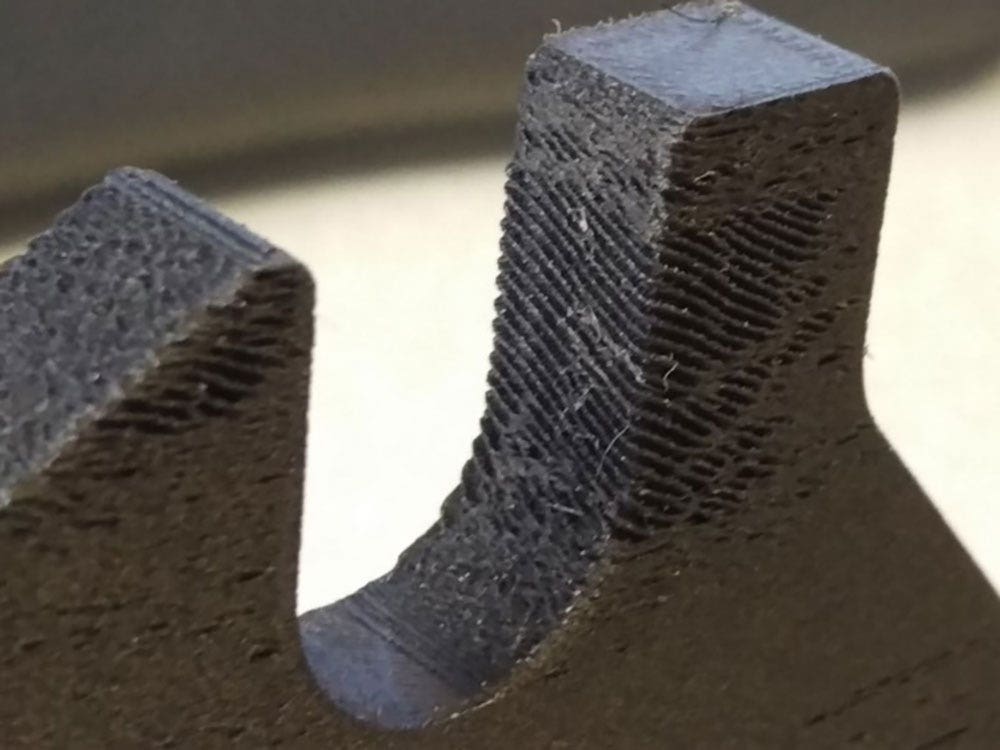

Stringing

A consequence of nozzle drip is that when the printer is not extruding plastic material, it will continue to drip out of the nozzle. This will result in a phenomenon known as stringing and can be identified by the presence of several undesired “strings” of material attached to the surface of your prints, particularly between separate parts or isolated features.

“Crackling” and “Popping” Sounds

If you hear crackling and popping noises coming from the nozzle of your machine while you print, you are likely printing with wet material. This is caused by the water in the filament turning to steam and expanding as it is melted. This forms bubbles in the plastic, which most often pop when they exit the nozzle, which results in a “popping” or “crackling” sound that will emanate from the plastic nozzle on your printer.

Steam Coming Off the Nozzle

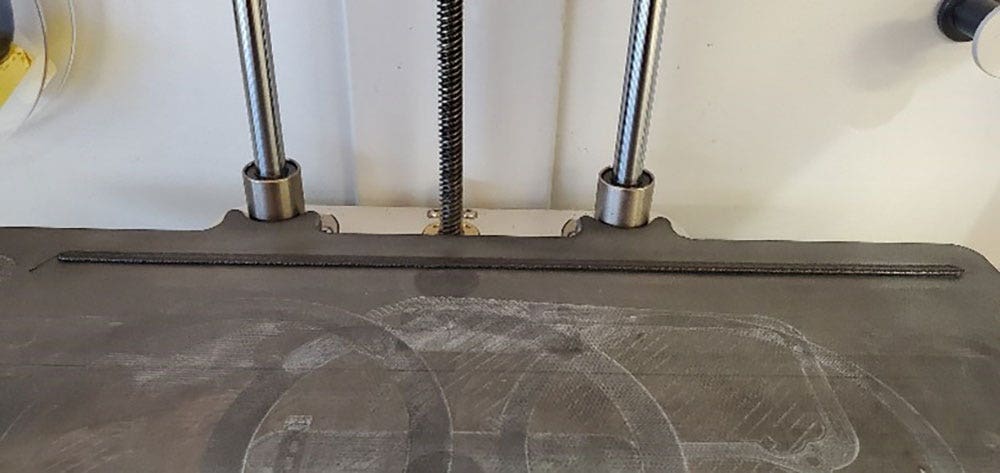

When printing parts with wet material, particularly while the printer is printing a large purge line, you may notice that steam is coming off the nozzle. While this is normal while printing a large purge line after the printer has sat unused for a while, seeing steam come off your nozzle while your part is being printed or with subsequent purge lines is a sure sign that your material is wet.

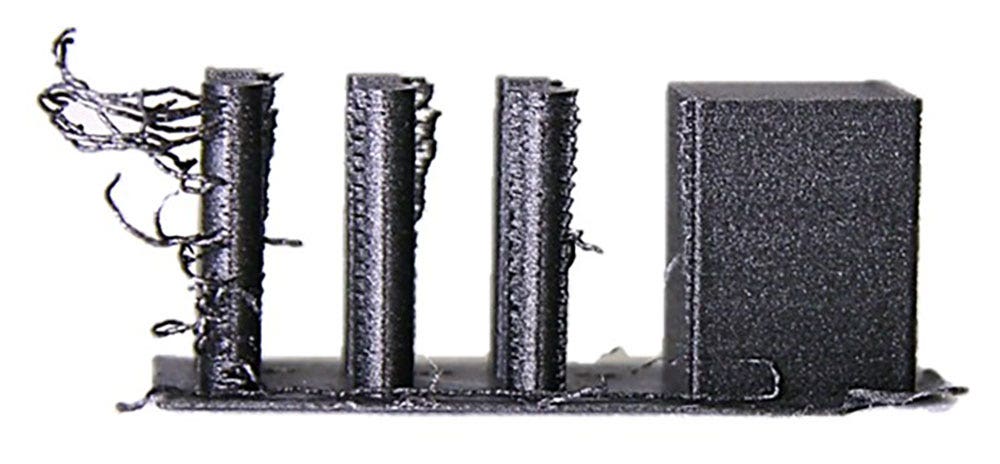

Bubbling, Under-Extrusion

If your material is very wet, you will notice that the surface of your parts will be rough and porous. Like with many of the other signs of wet material, the formation of bubbles in the plastic due to expanding steam results in a porous, rough and inconsistent texture on the surface of your part. These defects, particularly consistent under-extrusion, are most often caused by worn consumables. Ensure that your printer is maintained properly to prevent this from occurring and being confused with wet material.

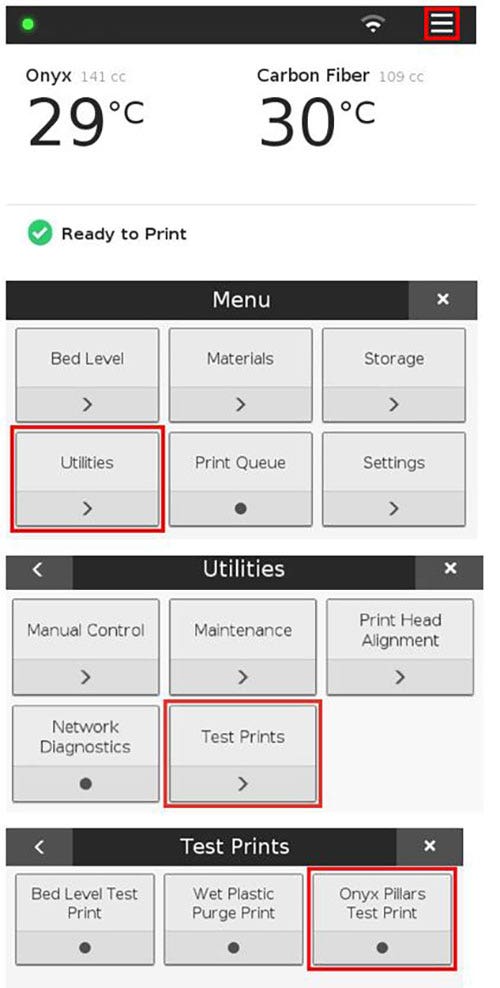

How to Test for Wet Material

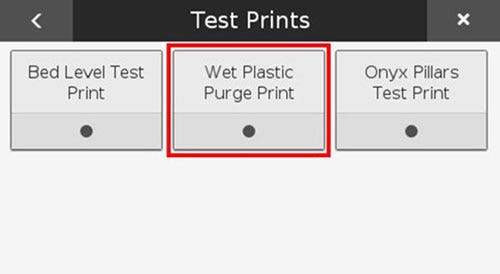

Aside from identifying the symptoms of wet material on your prints, Markforged has included a test print that can be used to help diagnose and highlight any problems that might be present within your system, including the presence of wet print material. This test print, known as the Onyx Pillars Test Print can be accessed by going to Menu > Utilities > Test Prints > Onyx Pillars Test Print on your device.

When printing this test print, please note that it will pause after 15 minutes so you can examine the interior of the print, so you will need to resume the print after this happens. If you see any of the signs of wet material mentioned above, particularly stringing, and possibly some extrusion inconsistencies while printing this part, you are likely printing with wet material (as shown below).

What If My Material Is Wet?

If you have found that your material is too wet to print with, you should discard the wet spool and switch to a new one. If you just opened and started printing with this spool and have stored it appropriately, please contact us and we will help you diagnose if this spool is defective.

Before discarding a spool, however, particularly if the material has been loaded in the machine and been left unused for an extended period of time, try running the Wet Plastic Purge Print a few times. This print can be found in the test prints section of the menu where the Onyx Pillars Test Print is located. If the material does not stop steaming after 2-3 attempts, you will likely have to discard the spool.

How to Prevent Material from Getting Wet

Since you will have to discard wet spools, it is important to ensure that you prevent your material from being exposed to moisture. You can do the following to ensure that you are always printing with dry filament:

Inspect Newly Received Material

Upon receipt of any new material spools, inspect the packaging for any tears or damage. Contact us if you find that any of your new spools feature torn or damaged packaging.

Keep Spools in Their Original Packaging Until They are Needed

Do not open your material before you need to use it, the packages that Markforged materials come in are sealed and contain desiccant to keep them dry. If new material is opened and not quickly placed in a drybox with its desiccant packs, it will need to be discarded.

Keep the Desiccant That Comes in the Bag with the Spool

When storing or loading Markforged plastic materials, make sure to always store the spools with the desiccant packs that came in the packages with them, and only store them with these desiccant packs. When you load a spool into your printer’s drybox, make sure that you place the included desiccant packets in the bottom corners of the drybox. When you remove a spool from the drybox, make sure to remove the old desiccant packs with the spool as well. If you are exchanging two open spools, make sure to keep the desiccant packs that came with each spool with the spool they shipped with respectively.

Keep In-Use Spools in a Drybox

If you need to switch materials (for example, from Onyx to Nylon White), make sure that you have a spare drybox on hand to store the spool that is not in use. Markforged recommends that you have a Pelican 1430 case (or similarly sized airtight container) on hand for each spare spool you need to store.

If you plan on keeping unloaded filament in your printer’s drybox, make sure to remove the feed tube from the adapter and insert the included plug to seal the drybox.

Pay Attention to Shelf Life

The minimum shelf life of an unopened plastic spool is two years, and an open spool properly stored in a drybox can last for up to one year. If these intervals are exceeded, you may run into issues with your plastic material.

If you keep your filament stored properly and know what to look out for, you will seldom be printing with wet filament.

For more information on this subject, review Markforged’s material storage and print issue troubleshooting pages. If you have any Markforged or 3D printing-related questions, please contact us and we will do our best to help you!