Are you intrigued by the possibilities of 3D printing in aerospace but overwhelmed by the complexities of certification and documentation? Look no further than Markforged composite 3D printing, a game-changer in the industry.

Advanced Materials for Aerospace Innovation

In recent years, the use of 3D printed parts in aerospace has soared, thanks to innovative materials from Markforged like Onyx FR-A and Carbon Fiber FR-A. These aerospace-grade materials offer unprecedented lot traceability, opening doors to new applications and enhancing flight-related processes.

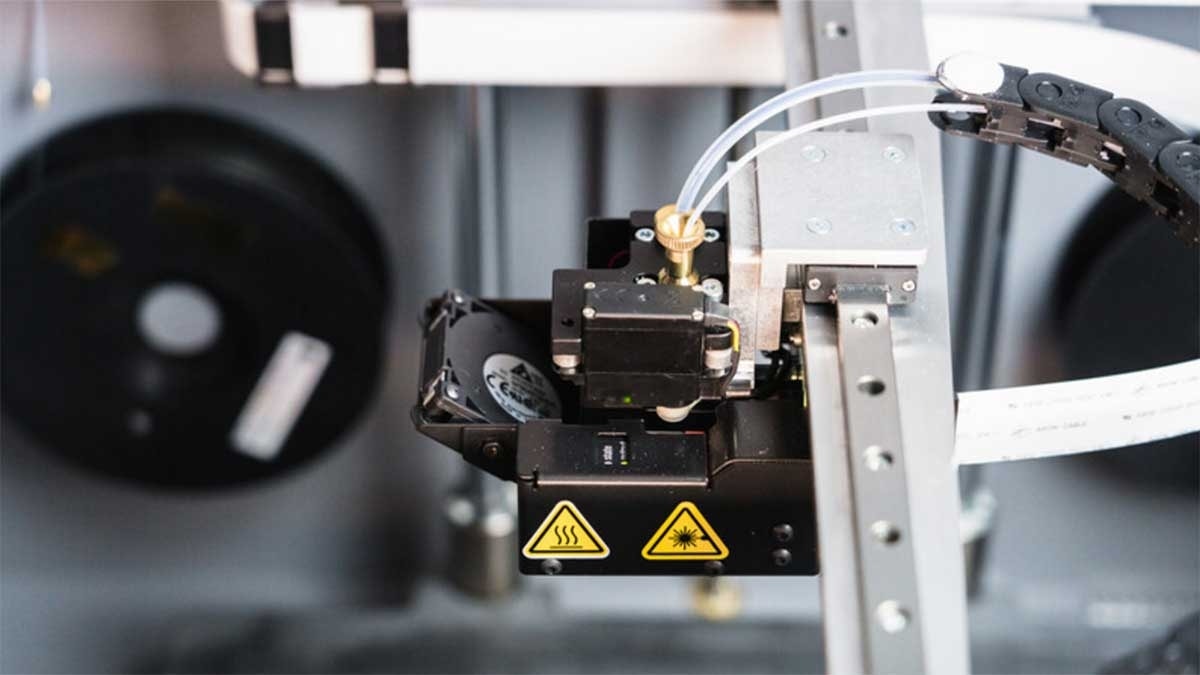

Precision Engineering for Unparalleled Quality

But it’s not just about materials – Markforged’s printing systems are advancing rapidly, incorporating features like automated part scanning for precise dimensional accuracy. This ensures that every component meets the highest standards of quality and safety.

Explore the Future of Flight

Interested in delving deeper? Join Chloe McGuffin, Aviation Application Engineer at Markforged, and additive manufacturing specialist Alan Kelly from Hawk Ridge Systems for an enlightening aerospace-focused webinar. Discover how Markforged composite 3D printing is reshaping the future of flight.

Have a question? Contact us to learn more about Markforged and aerospace today!