In today’s business climate with more and more technologies and competitive solutions emerging, it’s more important now than ever to incorporate integrated end-to-end solutions. This is true in the world of digitally manufacturing parts as well. Having the most cutting-edge CAD software, hardware, and post processing equipment integrated seamlessly can give you a competitive advantage over the competition. End-to-end solutions enable companies to manage the entire manufacturing process—from creating 3D models, fabricating physical parts, to post-processing—without relying on external vendors that could disrupt production or lower quality.

End-to-end solutions allow you to go from the very beginning to the very end of the manufacturing process. In the world of digitally manufacturing parts, this would mean having software or scanners to make or reverse engineer your models, 3D printers to produce the physical part, and then post-processing equipment to take it from raw to a completely finished professional part. Companies that have fragmented systems face several risks including disrupting production, higher manufacturing costs, and delays. This happens because they don’t have full control over the process. For example, imagine you are outsourcing an important tool that’s critical to your manufacturing process to XYZ Inc. If they decide to lay off some of their operators to reduce internal costs, that might delay the tool and thereby disrupt your production. You are at the mercy of not only the uncontrollable issues that affect your company but also those that affect the companies to which you outsource parts. Imagine that XYZ Inc decides to buy a less expensive machine to make your tool which benefits them but slightly reduces the quality of the part. Without the advantage of full control over the process you cannot fully maximize quality and efficiency.

Digitally Manufacturing Parts from Start to Finish

Hawk Ridge Systems offers many amazing tools to help digitally manufacture parts from start to finish. To start the process, first you will need to make a 3D model of the parts you want to create. Hawk Ridge Systems sells SOLIDWORKS, which is the most popular 3D modeling software in the world and for good reason.

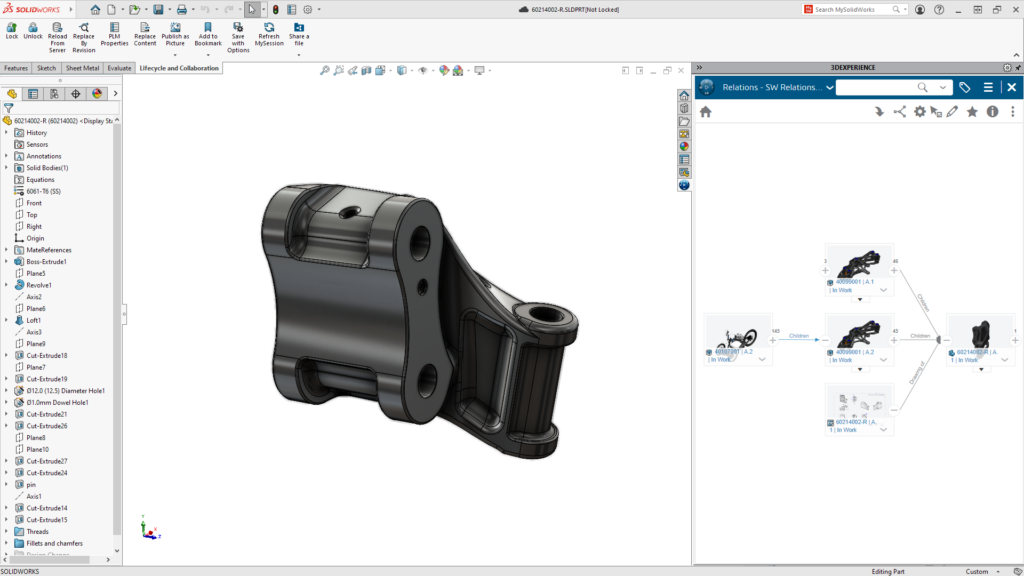

SOLIDWORKS has earned its reputation as one of the most popular CAD programs for mechanical design, trusted by engineers and designers across a wide range of industries. Whether you’re crafting detailed assemblies, designing intricate parts, or creating manufacturing drawings, SOLIDWORKS offers powerful tools that are intuitive and effective.

One of the standout aspects of SOLIDWORKS is how well it’s suited for designing 3D-printed parts and assemblies. Many of the core solid modeling features within SOLIDWORKS, like extrudes, revolves, and sweeps, create analytical geometry that is well-suited for all types of additive manufacturing. While designers are creating these parts, they can take advantage of features like draft and undercut analysis to look for areas of the part that certain print technologies might struggle with. If you’re starting your design from a previous print, SOLIDWORKS 2025 can even automatically convert mesh bodies to BREP solids, so you have a smooth body ready for editing. When it’s time to make the part, SOLIDWORKS allows you to export your model directly to a variety of file printer-friendly formats including .STL, .3mf, and .amf.

Another big advantage is SOLIDWORKS’ ability to simulate your designs under real-world conditions. For example, you can test how your 3D-printed parts will respond to static loads or temperature change. This can help optimize a design for less material usage and give you a great candidate for further print optimization, especially for complex or functional prototypes.

While SOLIDWORKS itself is a powerhouse, its integration with the 3DEXPERIENCE platform adds even more value. 3DEXPERIENCE connects your team, tools, and data through a cloud-based hub, making collaboration and lifecycle management easier. This is a good advantage if you’re 3D printing projects, where designs often evolve rapidly.

With 3DEXPERIENCE, you can store, share, and manage your design files securely in the cloud. Need to make a tweak? Team members can review and provide feedback in real-time without juggling endless email threads or multiple versions of the same file. The platform’s revision control and change management tools ensure that everyone is working on the right version of the design. Plus, the cloud-based system is accessible from virtually any device, which means you can take your work with you, whether you’re in the office or on-site.

The platform also complements SOLIDWORKS with specialized apps like xShape, built specifically for creating complex sub-D surfaces, giving users focused tools without unnecessary clutter. It’s this flexibility that makes SOLIDWORKS and 3DEXPERIENCE such a powerful combination.

Another way to produce models other than making them from scratch is with 3D Scanners. A relatively small piece of equipment can scan a physical part and produce a digital model. Hawk Ridge Systems carries several brands of scanners including Artec and Hexagon. Artec scanners are lightweight and versatile, which makes them ideal for applications like reverse engineering. Hexagon scanners are high-precision, so they excel with quality control and inspection applications.

Once you have your 3D model, then the next step is printing the physical part on a 3D printer. There are many technologies available in the 3D printing industry, and they all have their nuances, advantages, and disadvantages. HP’s printers including the 5200, use Multi Jet Fusion (MJF) to produce parts. This process is fast, so applications where parts need to be made in significant volume with complex geometry are perfect for MJF. Formlabs is the king of versatility and primarily uses SLA and SLS processes to produce parts. The Form 4 is an SLA machine that offers over 40 resins from flexible materials to true ceramic, and everything in between. Their SLS machine the Fuse1 is a powder printer, so it excels with complex geometry and speed similar to MJF but in a smaller, more economical, package.

Now that you’ve produced your parts, the next step is making them look finished and professional. Depending on what you want your part requirements are, it might make sense to use one or perhaps a combination of several post processing steps. Hawk Ridge offers several options for vapor smoothing, dyeing, and tumbling/polishing parts.

The vapor smoothing process is in essence fairly simple. You expose a part to alcohol or acetone vapor typically, and in just a few minutes the surface has been smoothed. It’s very effective when combined with 3D-printed parts, and there are several reasons why one might consider using this process. The most obvious reason is to make the surface finish of parts more aesthetically pleasing. The 3D printing process often leaves behind layer lines which can be eliminated by melting them together with vapor solvent. Parts that show defects left behind from 3D printing can be smoothed until they resemble injection molded parts.

Another benefit to vapor smoothing is its ability to seal parts and make them more or less watertight and airtight. FFF parts will have porosities which are formed due to the printing process, so if there’s internal channels or if it’s an application that holds pressure then this can improve the part immensely.

A lesser-known benefit to vapor smoothing is that it greatly improves the strength of 3Dprinted parts.

Check out this fun impact testing that AMT has online. When the solvent smooths the surface, it also melts the layer lines together. This improves the surface strength which makes parts much more resistant to layer delamination and bending forces. Hawk Ridge Systems carries two different vapor smoothers; namely the Dyemansion Powerfuse S and the AMT Postpro which are both great options.

If you are using one of our powder systems like the previously mentioned SLS or MJF machines, then bead blasting and polishing might be part of your process already. These processes require removing surface powder from of the parts after printing, which requires a bead blasting cabinet or a machine like the Formlabs Fuse Blast. The Fuse Blast is a multi-purpose post-processing tool created by Formlabs but could be used in conjunction with any powder printer theoretically. For the bead blasting process, parts are placed in a bin and then mixed with media to remove the surface powder left behind by the printing process. The best thing about this process is that it’s automated and requires very little user intervention. For folks producing a high volume of parts, having a machine like this to complement their powder printing is a no-brainer.

To go one step further, for a truly smooth and professional looking part, the Fuse Blast can also polish parts as well. The polishing function is an optional upgrade, which produces not just a smooth part but one that’s semi-gloss, scuff resistant, and ready for dyeing. It requires a separate drop-in module and special media for polishing. Once your parts are blasted and polished, now it’s time for dyeing.

(Dyemansion Dyed Parts)

Hawk Ridge Systems carries the Dyemansion product line, which has an excellent solution for dyeing in the DM60. Parts are simply placed in a basket which is inserted into the machine, and then 2.5 hours later your parts are colored and finished. The process uses DeepDye Coloring (DDC) which penetrates deep into the part, producing a fade/scratch-resistant and consistent result.

Hawk Ridge Systems: Your Partner for End-to-End Manufacturing Software and Hardware

Integrated systems streamline digital manufacturing, giving businesses full process control, higher efficiency, and superior product quality. CAD solutions like SOLIDWORKS, alongside complementary tools like 3D printers, scanners, and post-processing equipment, ensure seamless workflows from model to post-processed part. Hawk Ridge systems can help you drive excellence in your business with end-to-end solutions for digital manufacturing.

If you would like to learn more about our software and hardware offerings, contact us here and one of our experts will be happy to provide a consultation.