Engineering Spotlight: Matt Fisher

Matthew is an application engineer who specializes in 3D scanning. Starting off as a SOLIDWORKS user, he now employs a variety of 3D scanners to inspect, reverse engineer, and create product renderings. With an interest in digital preservation, he also uses 3D scanning to capture unique finds in local cities and parks.

Why Engineering? When did you know you wanted to pursue engineering and design?

I knew I wanted to do something with math, drawings, and design. So, it was either an engineer or an architect, I felt. The first time I finished an engineering-like project (wiring lights and switches for a puzzle) I felt very accomplished and wanted to pursue it more.

Why Hawk Ridge Systems?

I like the variety of projects I get to work on and the ability to teach other engineering tools. I feel like each week there’s something unique I get to work on, or I get to use neat tools for my own projects.

Advice to people considering engineering as a career?

It seems daunting at first, but as you work more, you will pick up the principles and how everything works together. Each time you finish a project you’ll keep that knowledge to apply to the next… and so on until you can get something new to work on and you can say “I’ve done this!”

Also, you learn better working on a project interesting to you and your hobbies.

What’s the most fun or quirky project you’ve ever worked on?

Scanning a t-rex tooth and skull – I enjoy anything to do with archaeology or paleontology.

Probably the best combination of fun, quirky, but work-related project was when a new LiDAR scanner needed to be tested. This is used to scan large spaces and in extreme environments, so we thought, no better place than a lava-tube cave! We packed everything into a car, drove about 3 hours out of town, and set up a couple hundred feet into the cave.

We documented the entire process, and we wrote a blog about it here: Testing the Artec Ray 3D Scanner in Extreme Environments.

Favorite side or pet project?

Any kind of issue I can fix with my 3D printer and CAD software is great. Saved so much money and hassle by making and printing a part in <1 hour.

For example, I needed to hang a curtain up but there was no way to attach the curtain bar to the walls without getting some kind of shelf or hook to hold it in place. Within about an hour I measured the diameter of the bar, made a printable holder to screw into the wall, and installed everything. A year later it’s holding up well!

Or, if it isn’t house-related, I’m printing gifts/items for the different games I play with the neighbors and friends. If you need an army of Wizard Frogs for Dungeons and Dragons – why not make it yourself?

Favorite client engagement? Why? What problem did you get to help solve?

Going to an open house event at a university to show off 3D scanners and printers for their students and research. It’s great to show how the technology has grown and hear all the ideas on how it can be used once they learn the capabilities. Sometimes it takes working with students who are first learning an industry to hear how these tools can work for projects you would have never thought of!

Recent work or side project that shows why you love engineering?

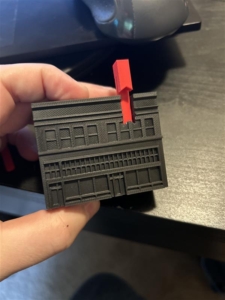

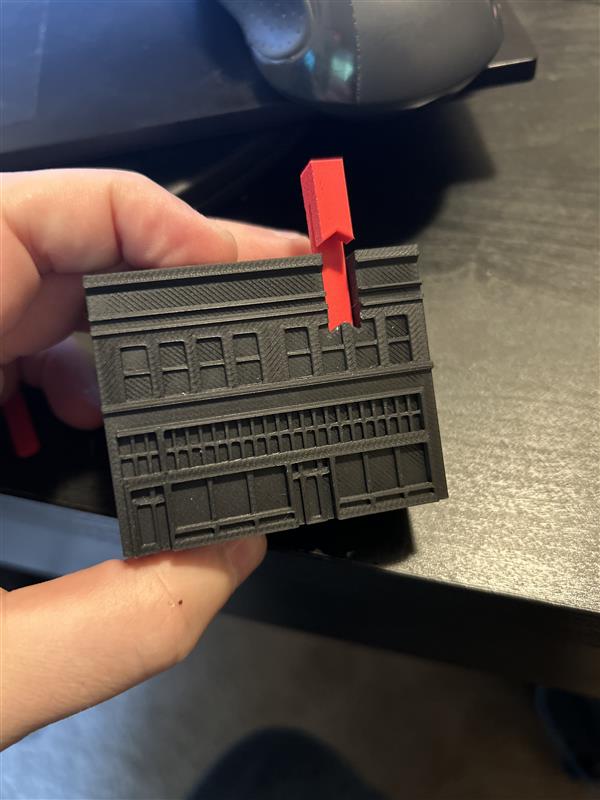

I designed and 3D-printed ~500 mini buildings for a charity event of a library opening. Great to work with local communities and design something unique like the building.

What are you reading/watching/learning/playing currently?

Watching, reading, and playing several different things all related to sci-fi… it’s rare that all of them line up with the same genre.

What do you want to learn next?

Getting back into electrical and light-based projects. Maybe magnets? Maybe something to expand my knowledge on things unrelated to mechanical design and how to drive those designs.

Favorite engineering or dad joke or meme?

If duct-tape can’t fix it nothing can.

What’s a recent engineering trend or innovation you’re excited about?

New materials and types of 3D printers. From printing flexible shapes, organic materials, and clothing – possibilities seem endless! For example, FormLabs is always innovating their resin materials to meet new engineering needs. The fact you can print in Silicon, Tough Resin for moldings, or a draft Resin for casing is crazy! And the speeds just keep increasing, so it’s becoming easier for smaller shops to start adopting 3D printing vs. traditional manufacturing.

Also some of the new AI tools for engineering design have been interesting to learn about. Tools to help automate workflows or give ideas on designs. I think it’ll be interesting to see how it can help people unsure about how to start a project by giving guidance.

With a combination of these AI tools and 3D printers, maybe we’ll see digital workshops becoming more common and easier for people to get their ideas out into the real world!

Where can people follow you online or see more of your work?

I don’t post much online besides on our Hawk Ridge Systems Blog and our YouTube channel. You can also check out my short video guide, presented at the Design to Manufacturing Conference: “Adding Custom Touches to Your Designs with 3D Scanning.”