In a previous blog, we used the

Compare Geometry

tool to analyze two versions of the same part to quickly identify any

geometric similarities and differences. This time around, we’re going to take

a look at the Compare Features tool. The Compare Features tool works very

similarly to the Compare Geometry tool, but instead identifies the differences

in actual solid features, including appearance properties.

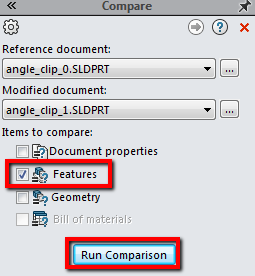

To use the tool, click on Tools > Compare > Features.

This will turn on the Utilities Add-In if it was not already turned on, and

will also expand the Task Pane with the Compare tool active. From here we can

select the two files we want to compare features. If you already have the

files opened in SOLIDWORKS, select them from the drop down menus for Reference

and Modified Documents. If not, you can browse for each of the files. Under

Items to Compare, select Features and click

Run Comparison.

Compare Features references the FeatureManager Design Trees from the two parts

and compares the list of features by name and type. These features are

classified as either Unique Features or Modified Features. Unique features

have their own name and type and appear exclusively in one part or the other,

whereas Modified features have the same name and type and are in both parts.

When Modified Features are found, the tool pairs them together and compares

their individual parameters. This helps distinguish what features may have

been added/removed, or had parameter values changed from one version of a part

to the other.

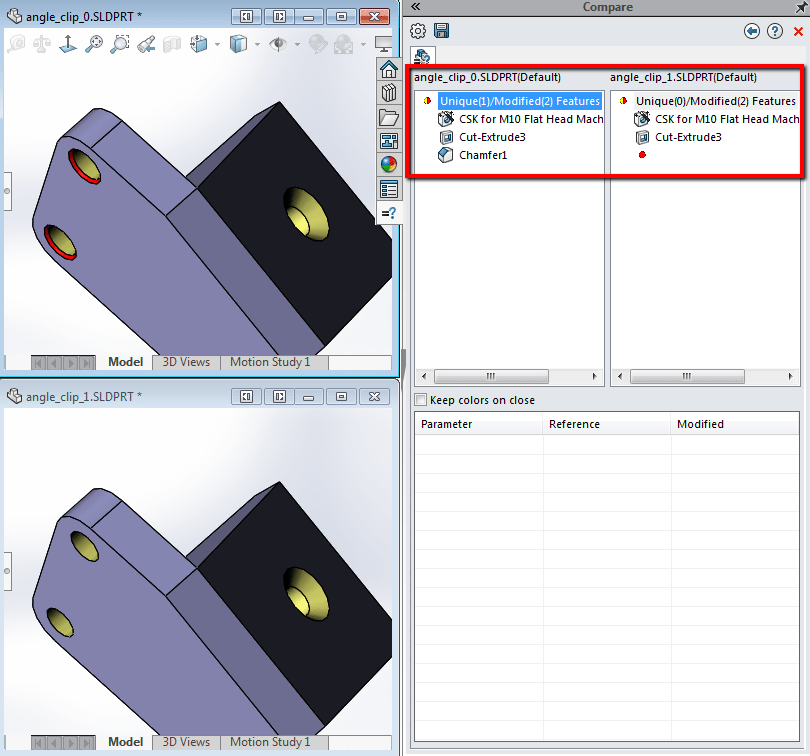

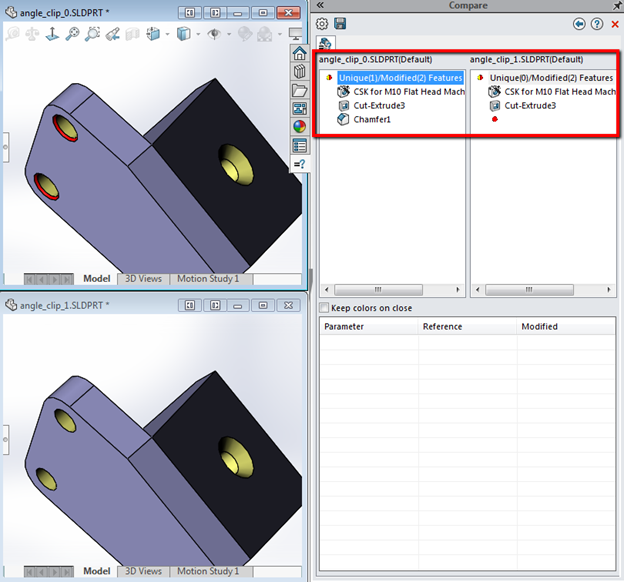

The results will be listed in the Task Pane, showing each of the

Unique Features and Modified Features for

each of the parts (if any). If you click the top level feature (Unique (1)/Modified(2) Features), the Unique and Modified Features are color coded in the graphics area to

show where the differences are between the two parts. It also shows a red dot

in place of a feature icon if a Unique Feature doesn’t exist in that version

of the part.

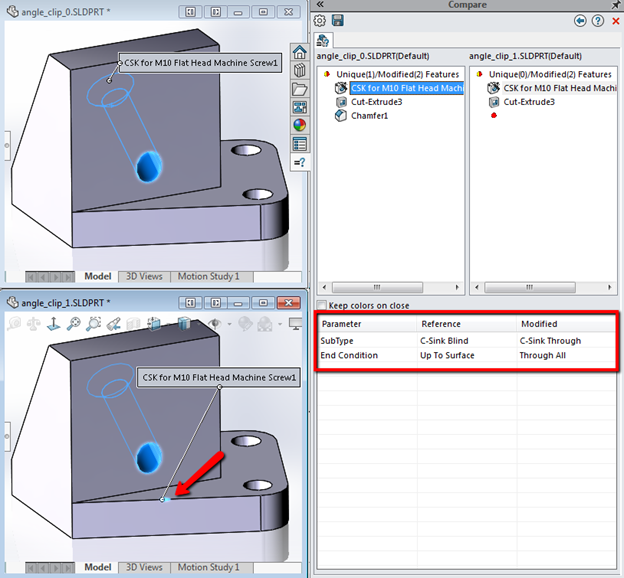

Furthermore, if you click on a Modified Feature from the list, the feature is

highlighted on both parts in the graphics area and the parameters for that

feature will be listed below. In this example, both parts have the “CSK for

M10 Flat Head Machine Screw1” feature, but one has an Up To Surface end

condition and the other has a Through All end condition. The tool will detect

any differences in sketch geometry as well, which is why Cut-Extrude3 is on

the list as a Modified Feature.

The results for the Compare Features can be saved in a by clicking on the

Save Report icon at the top of the Compare Task Pane. We can

see how the Compare Features tool differs from the Compare Geometry tool. Both

work great to quickly compare two versions of the same part, but each has

their specific uses. Be sure to check out our

YouTube channel for

more helpful tips!