The 411 on Design Automation and CAD Customization

In the not-so-distant past, the design process was exceedingly resource intensive. It took a lot of time, expertise, and effort to draft designs on paper. Those paper designs were then rendered into prototypes, which often failed and had to be reimagined and reproduced until the design was successful. The entire process was lengthy and expensive.

Clearly, this process was ripe for innovation. Then 3D CAD came along and did just that.

Now, automation has also joined the scene. With CAD customization and design automation becoming more common, the entire design process looks and feels completely different. But what exactly are CAD customization and design automation? How do these two concepts work together? What are the benefits?

Let’s take a deeper look.

The Basics: What is CAD Customization Versus Design Automation?

When there are common, repetitive, or tedious tasks in a design process, CAD customization can be extremely helpful. CAD customization is essentially when custom tools and technology are developed to support the automation of those monotonous tasks within CAD.

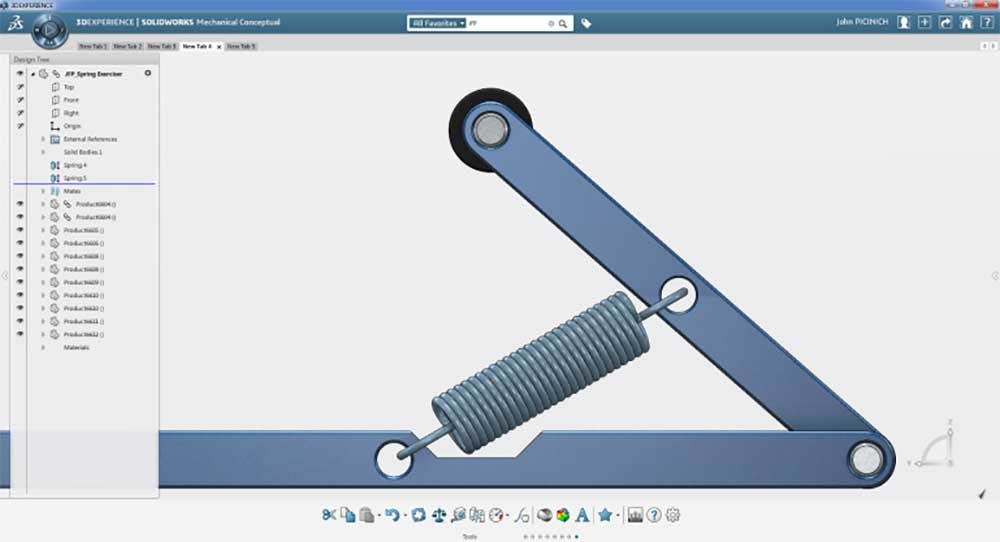

Design automation is one such tool. The process of design automation in tools like SOLIDWORKS allows engineering knowledge to be input into a system and applied in real-time during the development of a product where it makes sense. In other words, engineers can record theories and concepts, plus how and when they are applicable, into the software. Then, when appropriate, that knowledge can be automated into the design process.

This design automation allows engineering departments to focus their energies on less tedious tasks, freeing them up to focus on innovation, not repetition. By using a CAD software solution, customizing it, and employing automation, engineers and designers can save massive amounts of time while also creating better designs.

CAD Customization and Examples of Its Use

In what scenarios can CAD customization be applied? Though its potential use can be widespread, here are a few ideas for where CAD can be customized:

- Design automation

- Development of macros

- Creation of a user interface

- Drafting automation

- Menu (or API) and toolbar customization

What would this actually look like in practice? The following are a few helpful examples of process automation that can be accomplished through CAD customization:

- CAD models can be generated with little human input

- Process logs can be easily produced

- Bills of material for developed products (including a parts list) can be generated

- Drawings are more automated and less resource-intensive

- Drawing tables can be revised easily

As a result of leveraging automation, companies have found that the entire design process requires far less supervision, interaction, and human facilitation. Again, this streamlines the process, making it more efficient and less costly.

Why CAD Customization and Design Automation Matter

Automation is the way of the future. Customization is also going to be key going forward. When we put the two concepts together inside of a CAD design process, the results are stunning. It’s such an undeniable win-win that it wouldn’t make sense not to do it!

When CAD customization and design automation are integrated into a CAD design process, the final design is better, can be produced faster, and is cheaper to produce overall. Companies who are using CAD in this way also see greater system integration and more collaboration, increased productivity, and fewer human errors.

This means lower costs, higher quality, and fewer resources required. Companies can be more responsive to customer demand and more agile in the face of change. In the long run, these companies are better equipped to build a sustainable future for themselves, their workforce, and their stakeholders.

Innovation is another incredible byproduct. Designs are more precise, and changes and improvements can be made on the fly as the process organically unfolds. What’s more, employees are more satisfied with their jobs because they’re less focused on redundant tasks and more focused on creating better designs.

To put it succinctly, the benefits are far too great to pass up.

Transforming Your 3D Design Efforts with CAD Customization

With the advantages almost too numerous to list, it is clear that CAD customization and design automation are worthwhile pursuits in the world of design. Providing innovative solutions, shortened lead times, and a less resource-intensive process, CAD and automation are the way of the future.

Better, faster, cheaper … these trends are here to stay!

It takes time and effort to implement a new software solution like SOLIDWORKS, but it is worth it! When you are ready to level up your next 3D design project and increase your productivity and efficiency using top-of-the-line CAD software, contact us and our team of experts at Hawk Ridge Systems can help with any questions you may have. Thanks for reading!