In the world of 3D printing, one file format has dominated the industry for decades – the STL file. It has reigned supreme and has been around since the inception of 3D printing. Developed in 1987, the STL (Stereo-Lithography) file format was created by 3D Systems for use on their first SLA 3D printers and has remained largely unchanged for over 30 years. Even though the STL format is a relic of the old days of rapid prototyping, it is still one of the most commonly used formats to save 3D mesh data for use in 3D printing.

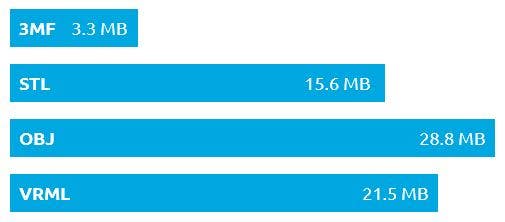

STL files have their strengths. They are simple, reliable and widely supported by virtually all 3D software packages in the engineering, design and additive manufacturing industries. Yet, STL files are extremely limited. They only contain simple shape data as defined by a list of x, y, z coordinate points in space. If the mesh is significantly dense and complex, they can often have extremely large file sizes. STLs also do not have the ability to save a variety of useful additional information and lack features such as:

- Scale data

- Unit (imperial/metric) data

- Color data

- Texture-mapping color data

- Support structure data

- Metadata

- Manufacturing data

As the additive manufacturing industry continues to develop and evolve, the limitation of the STL format has become more readily apparent. The time has come for an updated, more robust file format that is ready for the demands of the modern age of 3D printing.

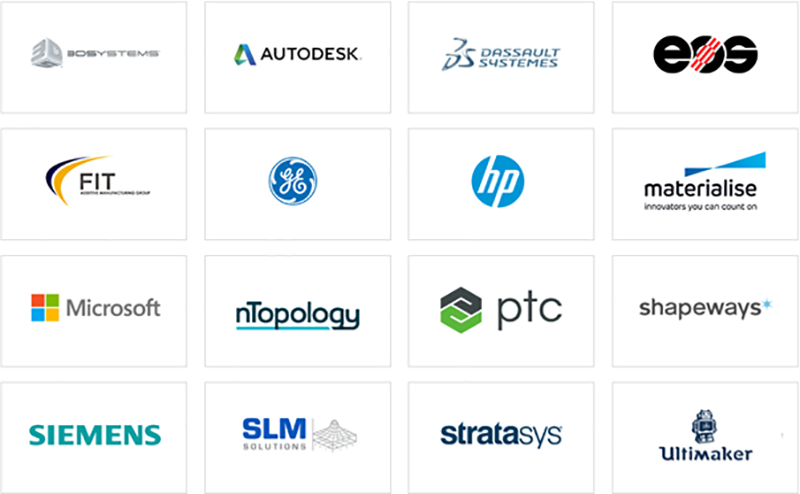

This is where 3MF or “3D Manufacturing Format” steps in. Several industry-leading companies joined forces in 2015 to develop a format that addressed the limitations in not only the STL format, but also other popular but aging 3D formats such as OBJ and VRML. Led by a group of companies such as Microsoft, Autodesk, 3D Systems and Dassault Systemes, the 3MF Consortium was formed with the goal to help advance the 3D printing industry.

Founding Members of the 3MF Consortium

Features of the 3MF Format

The 3MF format was designed specifically for additive manufacturing to keep up with the needs and development of a rapidly evolving industry. The new format takes the best elements from existing file formats and addresses their deficiencies to provide a rich 3D printing format packed with several built-in features, including:

- Complex shape data with low file sizes

- One or multiple textures

- Multiple color data

- Multiple materials

- Lattice and support structures

- Unit scale information

- Manufacturing process and slice data information

- AM build tray management

- Metadata (designer name, copyright and license info, description etc.)

- Built-in thumbnail images for asset management

- Open format that is fully extensible allowing for new innovation and broad adoption anytime new hardware or techniques are created within the industry

3MF Feature Comparison

The 3MF format is tailor-made for additive manufacturing and provides valuable benefits to additive manufacturing workflows that other formats lack.

File Size Comparison

Why Isn’t 3MF More Well-Known?

With such a robust feature-set, why is it that many have not heard of 3MF and why has the industry been so slow to use it? 3MF is still relatively new and the manufacturing industry can sometimes be slow to adopt a new standard. As a result, 3MF still has a lack of industry recognition. In addition, not all CAD programs and software platforms have native 3MF support. This is rapidly changing, however, as the list of software platforms and hardware manufacturers now supporting the 3MF format grows:

- 3D Systems, 3DXpert and 3D Sprint

- Autodesk Fusion360, Meshmixer and Netfabb

- Dassault Systemes CATIA / 3DEXPERIENCE and SOLIDWORKS

- HP Jet Fusion 3D Printing Solution

- Materialise 3-matic and Magics

- Microsoft 3D Builder, Paint 3D and Office 365

- PTC Creo

- Rhino

- Siemens PLM Solid Edge and NX

- Simplify 3D

- Ultimaker Cura

- nTopology Element

The 3MF format is an excellent update to the previous simple 3D formats more commonly found in use today. 3MF takes the strengths of STL, OBJ, VRML and addresses their weaknesses to create a well rounded, feature rich 3D format tailor-made for additive manufacturing. With numerous built-in features and near limitless extensibility, the 3MF file format is positioned to be the ideal format for the future of additive manufacturing. It’s time to let STL fade into the past and embrace the future file format of 3D printing.

To learn more about the 3MF Consortium and the 3MF format, visit https://3mf.io/, and be sure to check out our additive manufacturing page to see the latest in printing technology. Thanks for reading!