The old adage is “time is money.” Nowhere is that truer than in production based off CNC machining. The time it takes to produce a part (or many parts) is greatly improved using advanced CAM software, such as CAMWorks. Both stages in the production process can be affected by delays, which can increase the most crucial periods of time in CNC: the programming time and the machine’s cycle time.

The programming time is increased if the programmer must review not only the printed hardcopy of the drawing for tolerances, but also confirm that the 3D model matches. The machining time could suffer from extraneous moves if the tooling used is not robust enough. In the end, no amount of programming skill or efficient tooling can save the production time if an unforeseen collision causes the machine to go down to await repair.

Leverage CAM to Streamline Production on a Lathe

Within CAMWorks, there are three main functions that can aid in the improvement of the production time on lathes or mill-turns.

Tolerance-Based Machining

Tolerance-Based Machining (TBM) can analyze the part model and determine if machining tolerances were assigned. From there, pre-determined settings will apply the appropriate turning strategies based on those tolerances. This is a way to save time in the initial stages of programming by relying on the CAM automation rather than the programmer.

Prime Turning

Prime Turning is an innovative method which enables turning in all directions in a much more efficient way. CoroTurn inserts are used to achieve this higher level of turning operation efficiency. These robust inserts not only allow for turning in both directions, but can also reach increased speeds and feeds due to their construction.

Machine Simulation

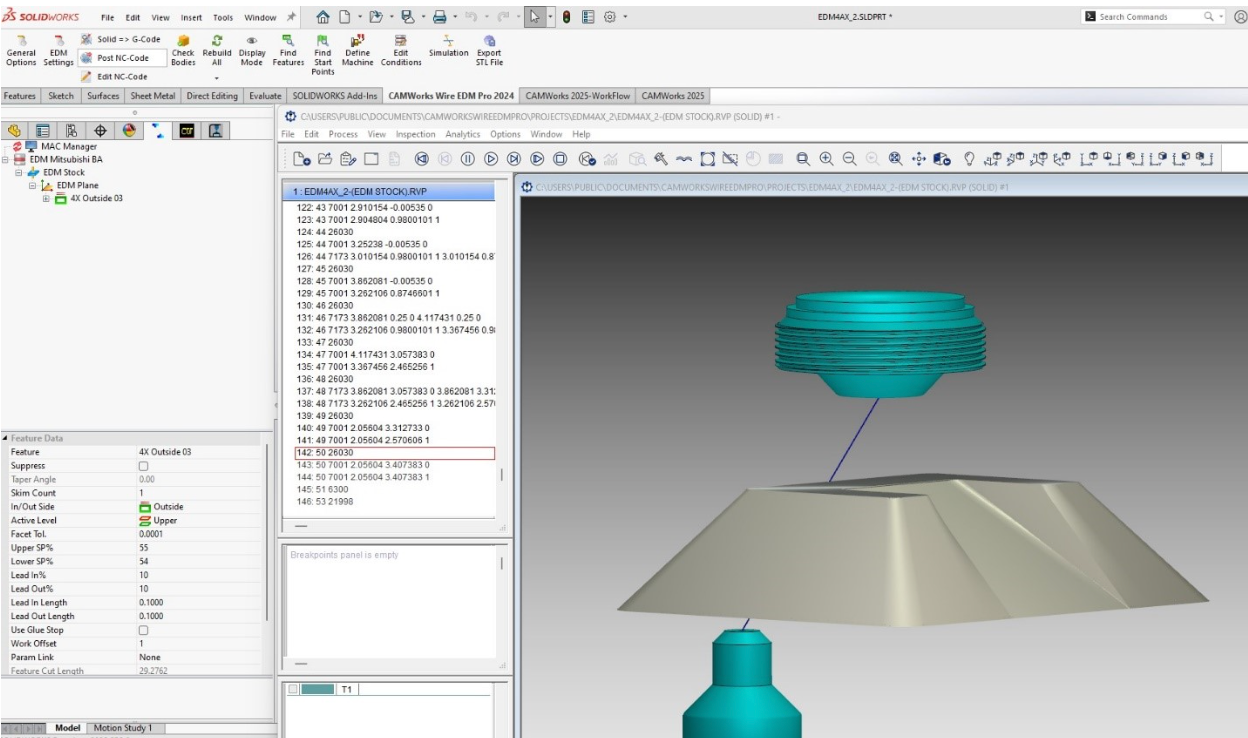

Machine Simulation is a common practice in Digital Twin technology and, in CAM, it can be used to confirm an error-free program. Issues such as a tool’s turret placement interfering with an operation and leading to a crash can be checked virtually in the simulation and easily corrected in the software before it becomes an even greater issue on the actual machine.

Watch the Webinar Now

In this webinar, we cover these three main functions that can help streamline the production on your lathes or mill-turns to decrease both programming and cycle time.

If you have any questions about CAMWorks and how to make the most of your CNC machining efforts, contact us at Hawk Ridge Systems and our team of dedicated CAM professionals will be happy to help!