SOLIDWORKS CAM

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

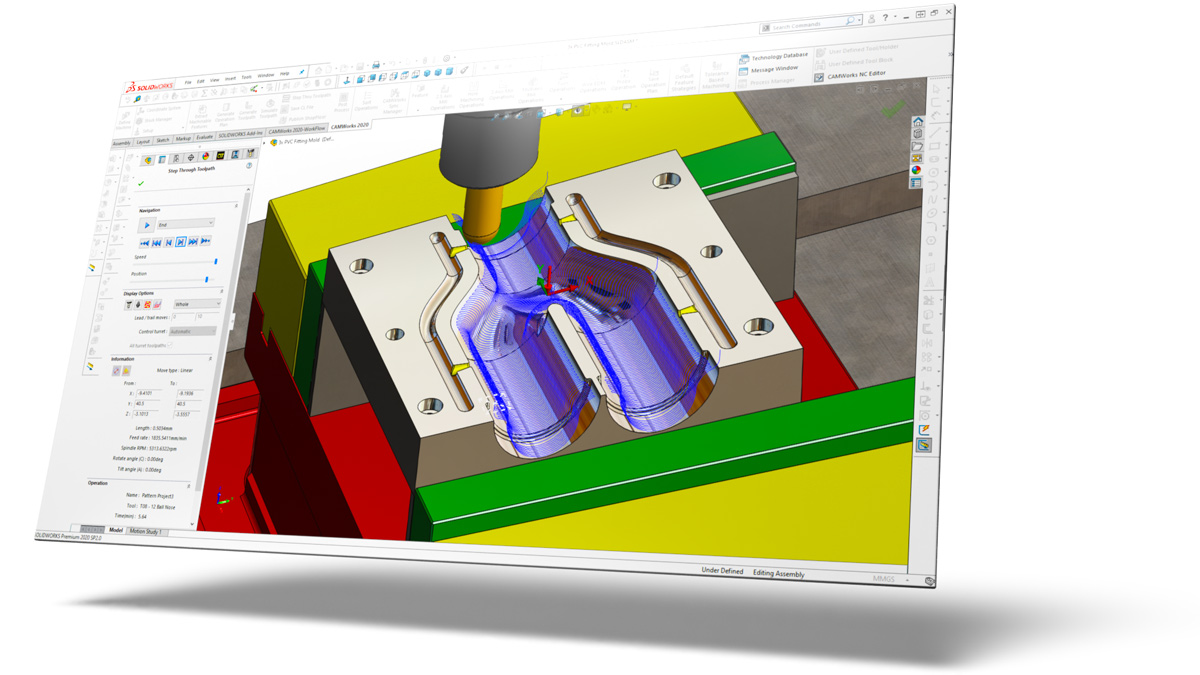

CNC Programming Automation Within SOLIDWORKS

SOLIDWORKS CAM makes CNC programming available on every engineer’s desk. Running natively in SOLIDWORKS, all tool paths are associative with the CAD geometry and can save the manufacturing data with the original file, making PDM implementation a breeze. SOLIDWORKS CAM Standard is free to you when your SOLIDWORKS license is active on subscription.

SOLIDWORKS CAM offers Automatic Feature Recognition and rules-based programming to radically enhance your manufacturing productivity. The SOLIDWORKS CAM Professional upgrade adds advanced capabilities including the high efficiency roughing engine VoluMill, turning, and programming in the SOLIDWORKS assembly environment.

Not a SOLIDWORKS user? SOLIDWORKS Machinist solutions offer you the full capabilities of SOLIDWORKS CAM, along with basic modeling functionality.

-

Rules-Based Machining

SOLIDWORKS CAM allows you to focus on critical areas of making your parts by using rules-based machining to improve the programming process while leveraging the tolerances that are assigned to components.

-

Tolerance-Based Machining (TBM)

TBM automatically creates CAM machine programs by using tolerances and annotations in 3D models and automatically adjusting asymmetric tolerances to mean tolerances for cutting tool strategies.

-

Knowledge-Based Machining (KMB)

KBM defines strategies and tools to best machine your part geometries once features are identified through feature recognition. This allows you to easily and automatically define repeatable machining processes to meet your company’s standards.

-

Associativity with SOLIDWORKS CAD

Changes made to a part design in SOLIDWORKS 3D CAD are automatically updated, applied, and reflected in SOLIDWORKS CAM.

-

Automatic Feature Recognition (AFR)

Automatic Feature Recognition can recognize certain geometry types not only as CAD features – including holes, pockets, bosses, and turn (Professional only). It can identify prismatic parts at a feature level based on machinable shapes.

-

Automate Machine Times

Easily automate calculations for machine time and compare that to traditional methods to ensure that all aspects of your part are accounted for before you commit to production.

-

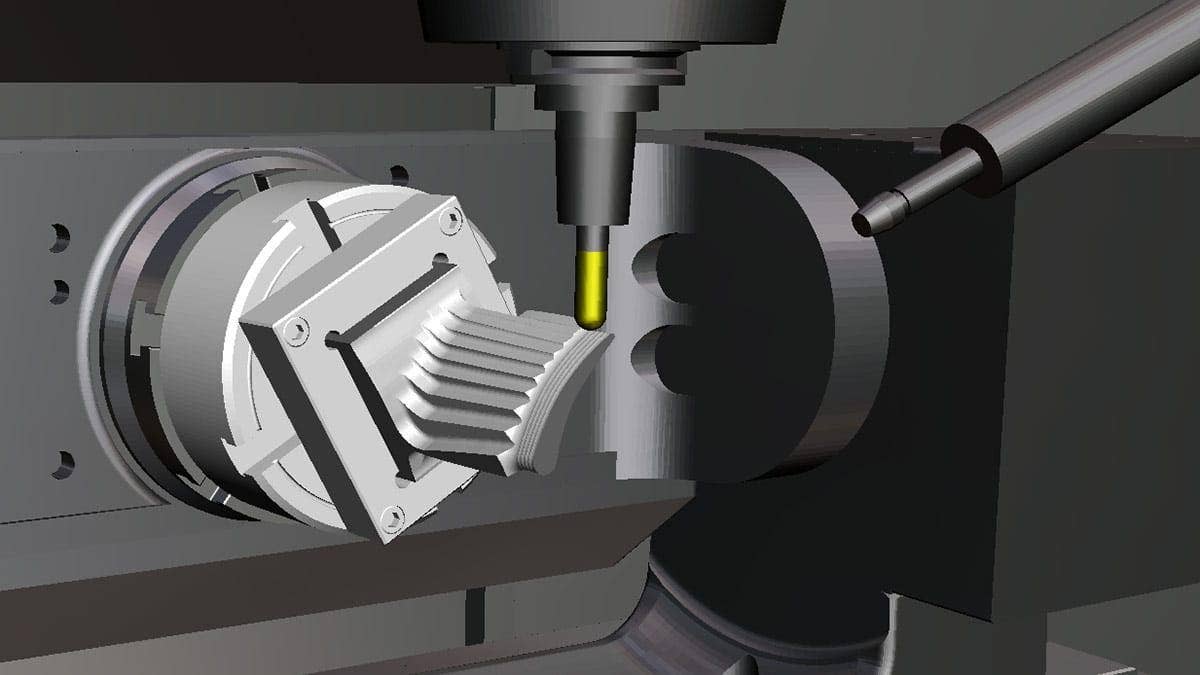

3+2 Indexing

3+2 indexing is a technique where a 2.5 Axis Premium milling program is executed with the cutting tool locked in a tilted position in order to use the five-axis machine's two rotational axes.

-

High-Speed Machining

Use 2.5 axis high-speed machining along with VoluMill technology to ensure a constant tool pressure through the entire cutting process. This technology uses a variable feed rate that allows the tool to cut at full depth. Shorten your cycle times, lower overhead costs, and extend machine and tool life.

-

Turning Capabilities

Take advantage of turning functionality including:

- face rough and finish

- rough and finish turn

- groove rough and finish

- rough and finish bore

- cut-off

- ID and OD threading

- drill

- tap on center

-

Part Modeling and ImportSOLIDWORKS Machinist features a part modeling environment where you can easily work with SOLIDWORKS part files or import many neutral file formats.

-

Assembly Modeling and ImportSOLIDWORKS Machinist Professional features an intuitive modeling environment where you can easily import and design fixtures, parts, or assemblies for manufacturing. In this environment you can quickly check fits and tolerances, import clamps and vises to ensure parts are made correctly, provide the necessary clearances for finished part removal, and even give direction to manufacturers on how you want your products built.

Alien Machine Worx Grows With SOLIDWORKS CAM

Alien Machine Worx creates differential covers with maximum strength and ease of use that provide big benefits for its off-roading customers.

Learn how this family-owned business uses the SOLIDWORKS-integrated, design-to-manufacturing solution to be able to easily go from idea to model, reduce prototypes, and determine the manufacturing costs before going to CNC.

Manufacturing Resources

Are Your CAM Tools Working Together? They Should Be.

Watch Webinar

Introduction to SOLIDWORKS CAM

Watch Video

Alien Machine Worx Success With SOLIDWORKS

Watch Video

3 Strategies to Master for Future Manufacturing Success

Download GuideFrequently Asked Questions

One great benefit of our CAM solutions portfolio is the flexibility it offers programmers in selecting the right level for their machining needs. Whether you’re just starting out with entry-level machining using SOLIDWORKS CAM or require more advanced capabilities like 3D to 5-axis machining with CAMWorks, we have the perfect solutions to match your requirements.

No, the hardware requirements are the same as those for SOLIDWORKS.

SOLIDWORKS CAM is compatible with any of the three levels of SOLIDWORKS CAD: Standard, Professional, or Premium. SOLIDWORKS CAM Standard is included free with any of those license types active on subscription.

You can program any file type that can be brought into SOLIDWORKS as solid bodies or surfaces.

Yes. Historically, the functionality of SOLIDWORKS CAM Standard was available in the 2.5-axis CAMWorks software and is ideally suited to programming many CNC milling jobs.

Hawk Ridge Systems offers courses ranging from self-paced, on-demand training with SolidProfessor, to live online instructor-led training, to onsite consulting. No matter your schedule or preferred learning style, we have a training option for you.

Services & Customer Benefits

Technical Support

Our global support team efficiently addresses your needs. We’re here to minimize downtime and costs when your machines encounter issues. If we supply a post processor, expect ongoing support and updates throughout your contract.

Unmatched Training

Our Certified CAM trainers draw from extensive software and real-world machining experience for your productivity. Choose from various training options, including self-paced, instructor-led, and private, tailored to your needs and learning style.

Professional Services

We offer comprehensive CAM and CNC machining software services, including swift implementation, free or customized post processors for seamless software-machine integration, and personalized consulting for ongoing productivity.