Hexagon AS1 and AS1-XL

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

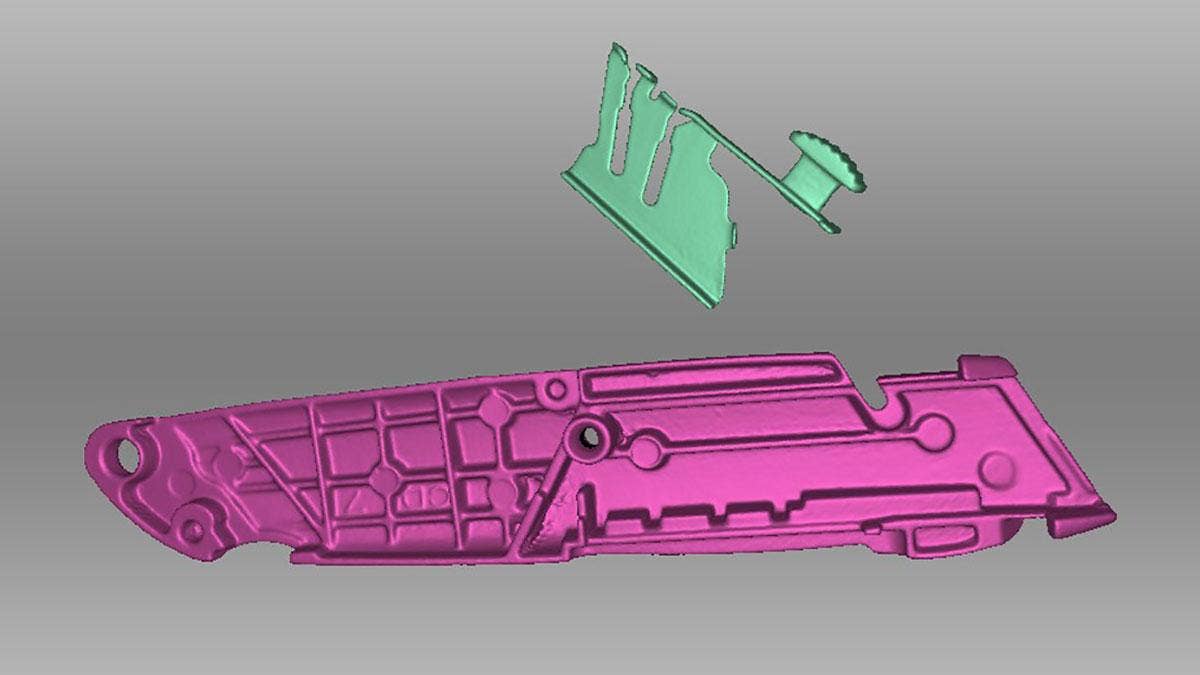

Cutting-Edge Blue Laser and SHINE Technology

Key Features & Benefits

Scan almost any surface with ease

Unmatched scanning speed

Hot-swap devices seamlessly

Setup profiles per task

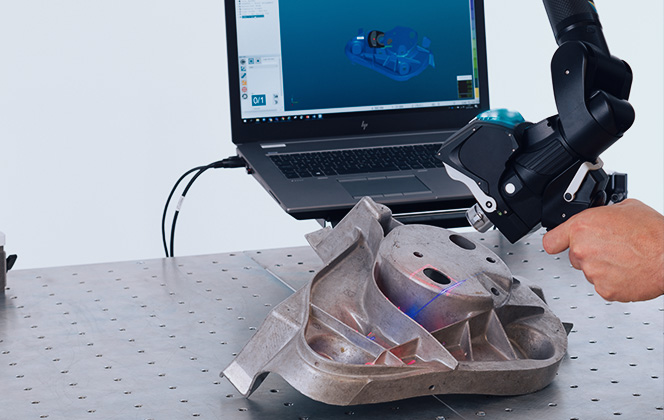

Lightweight and automation-ready

Technical Specifications

|

Features

|

AS1

|

AS1-XL

|

|---|---|---|

|

Accuracy

|

0.013 mm

|

0.134 mm

|

|

Scanning line width

|

150 mm

|

600 mm

|

|

Standoff distance

|

165 mm

|

700 mm

|

|

Point acquisition rate

|

1.2 million points/s

|

1.2 million points/s

|

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training, and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions, and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Services & Customer Benefits

Technical Support

Our scanning support specialists are 100% dedicated to our 3D scanning applications, have passed rigorous testing standards, and have extensive experience using our scanning products in the real world.

Unmatched Training

Every company is different, and when it comes to training for 3D scanning, one size doesn’t fit all. Hawk Ridge Systems can tailor a training plan to focus on the needs of your application.

Professional Services

Frequently Asked Questions

The SHINE Technology is designed to capture difficult-to-scan materials, like those that are shiny or semi-transparent, as well as duller materials, without needing to adjust any settings, even if it’s captured in the same instance.

The single-line laser allows for deeper hole depths and sharper edges to be measured compared to grid-based laser scanners. Operators can define the diameter of a cylinder using the scanner and define the depth with a probe for extra deep recesses.

3D Scanning Resources

Preserving History With 3D Scanners

Download Guide

3D Scan-To-CAD: How to Model Almost Anything

Watch Webinar

The Artec Ray 3D Scanner in Extreme Environments

Read Article