Formlabs Fuse Blast

Effortlessly clean your SLS 3D printed parts in minutes with Formlabs Fuse Blast. Save time, cut costs, and deliver professional-grade, touch-clean parts.

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Your Ultimate Solution for Professional Post-Processing

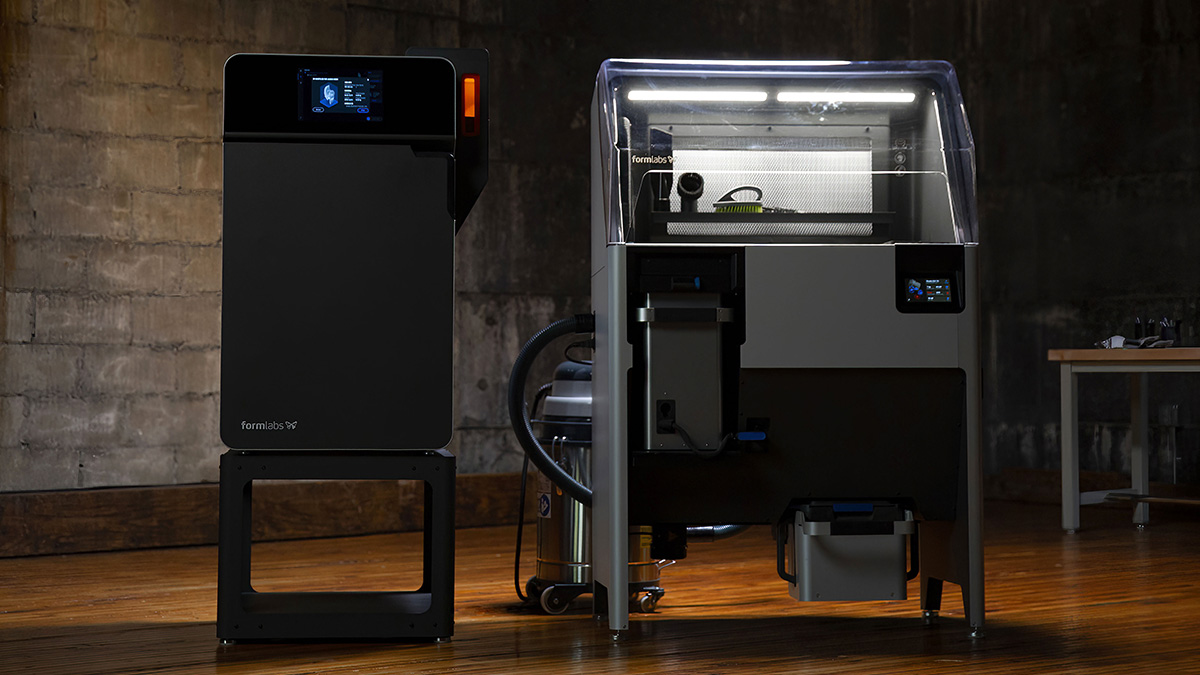

Elevate your powder-based 3D printing post-processing with Fuse Blast, a fully automated cleaning and polishing solution. Seamlessly integrated into the Fuse Series ecosystem, Fuse Blast delivers fast, consistent results, cleaning a whole build chamber in just 15 minutes.

With optional polishing capabilities, you achieve smooth, semi-gloss, and dye-ready surface finishes, ensuring professional-grade parts every time. Say goodbye to manual labor and hello to streamlined post-processing with Fuse Blast.

Key Features & Benefits

Hands-Off Cleaning

Quick Finish

Consistent Results

Professional Finish

Streamlined Workflow

Technical Specifications

|

Features

|

Fuse Blast

|

|---|---|

|

Printer Compatibility

|

Fuse Series SLS 3D Printers

Third-party powder bed fusion 3D printers |

|

Dimensions (W x D x H)

|

100 × 75 × 175 cm

39 × 29.6 × 68.7 in Height when open: 195cm (76.8 in) |

|

Weight

|

164 kg (without blasting media)

360 lb (without blasting media) |

|

Power Requirement

|

EU: 230 VAC, 3 A (no dedicated circuit or vacuum required)

US: 120 VAC, 6 A (no dedicated circuit or vacuum required) |

|

Connectivity

|

Wi-Fi: 2.4 GHz

Ethernet: 1000 Mbit USB: 2.0 |

|

Internal work area (W x D x H)

|

71 x 55 x 67 cm

27.9 x 21.6 x 26.3 in |

|

Accessible work area (W x D x H)

|

57 x 50 x 67 cm

22.4 x 19.6 x 26.4 in (basket removed) |

|

Compressed Air Requirements

|

Supply at least 10 SCFM at 90 PSI / 285 SLPM at 6 bar

Regulate pressure input between 90-120 PSI / 6-8 bar |

A Premier Industrial Design Studio Leverages Formlabs

Vital Auto, a top-tier industrial design studio specializing in automotive design, serves major clients like Volvo, Nissan, McLaren, and Lotus.

They utilize Formlabs Form 3L SLA printers and Fuse 1 SLS printers for high-fidelity prototypes and end-use parts. Their materials range from Elastic 80A Resin for prototype door seals to Nylon 12 for rugged components like air ducts, all crafted with precision and expertise.

Formlabs Resources

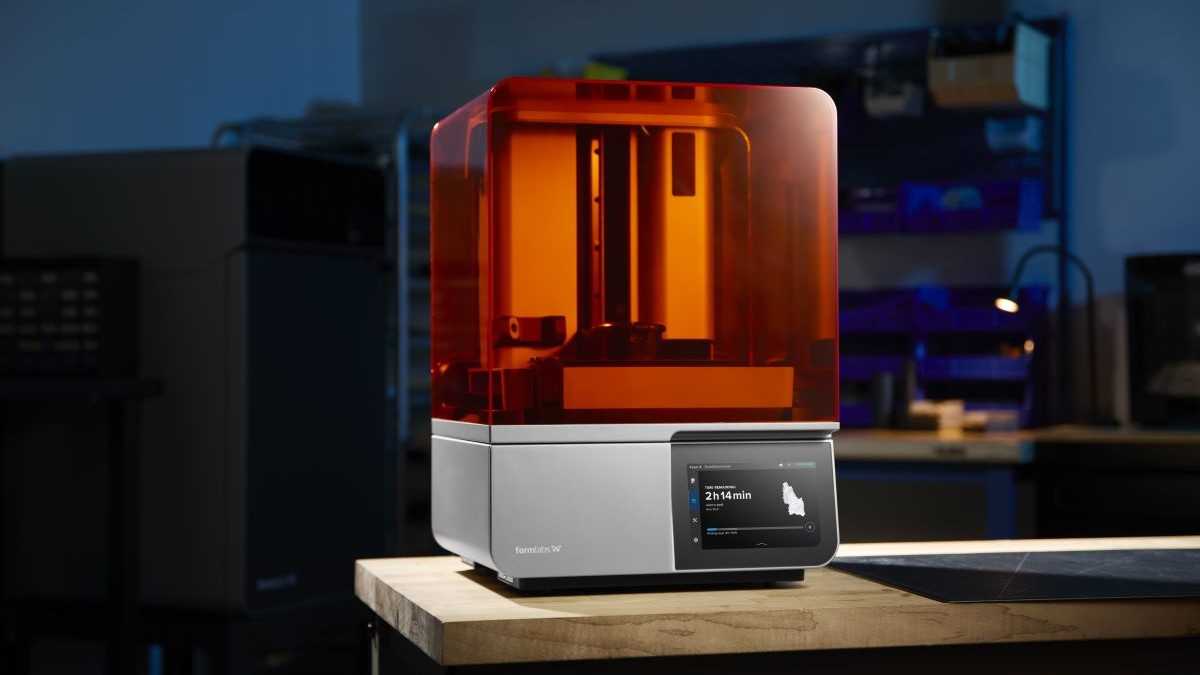

Formlabs Is Here! SLA and SLS Printers

Read Article

MedTech Additive Manufacturing in Space

Read Article

Speed Up Medical Device PLM Processes

Read ArticleFrequently Asked Questions

Fuse Blast comes with the following accessories:

- Transfer container

- Control pedals

- ESD wrist strap

- 7mm socket wrench

- Blast orifice (3mm)

- Blast orifice (4mm)

- T-20 driver

- Floor mat