Have you ever hoped that one day, there would be a way for you to utilize your

3rd party CAD data into SOLIDWORKS without having to go through the

process of saving it out as a STEP file or some other neutral format?

SOLIDWORKS 2017 has introduced a step in that very direction with 3D

Interconnect! In this 3 part series, we’re going to explore 3 workflows we’ll

see 3D interconnect best utilized:

-

To directly insert the 3rd party CAD data into SOLIDWORKS

assemblies to be used to mate and design around like any other SOLIDWORKS

component. -

To be opened as a base/derived part so we can add native SOLIDWORKS features

to the existing 3rd party design data. -

To perform feature recognition on the 3rd party design data, and

break the link to the party while still preserving faces and edge ID’s.

In this initial blog, we’ll explore how to turn on 3D Interconnect, see what

formats we’ll be able to import, as well as one of the main workflows on how

3D Interconnect will most likely be used.

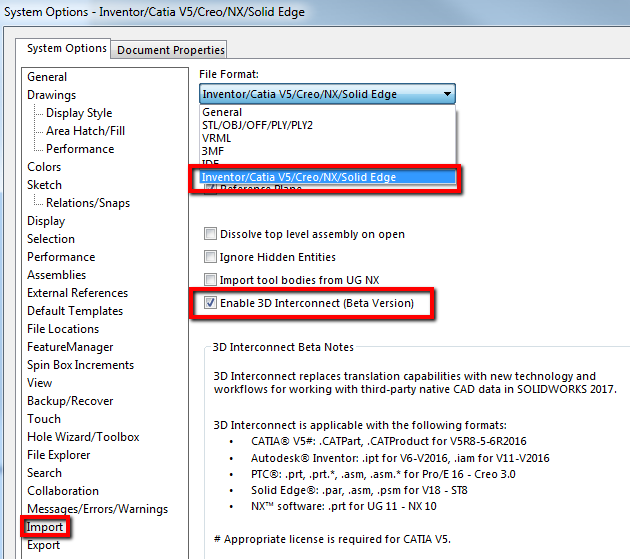

To be able to utilize 3D Interconnect, we want to access the ‘Import’ options

through ‘System Options’. While in the ‘Import’ Menu, we’ll want to change the

‘File Format’ to ‘Inventor/CATIA V5/Creo/NX/Solid Edge’. Once selected, we’ll

want to make sure ‘Enable 3D Interconnect’ is checked!

|

What are some of the formats 3D Interconnect can work with, you ask? Here they

are:

-

PTC

- .prt, .asm for Pro/E 16 – Creo 3.0

-

Autodesk Inventor

- .ipt for V6 – 2016

- .iam for V11 – 2016

-

Solid Edge

- .par, .asm, .psm for V18 – ST8

-

Siemens NX

- .prt for UG 11 – NX 10

-

CATIA V5 (SOLIDWORKS Premium)

- .CATPart, .CATProduct for V5R8 – V5R2016

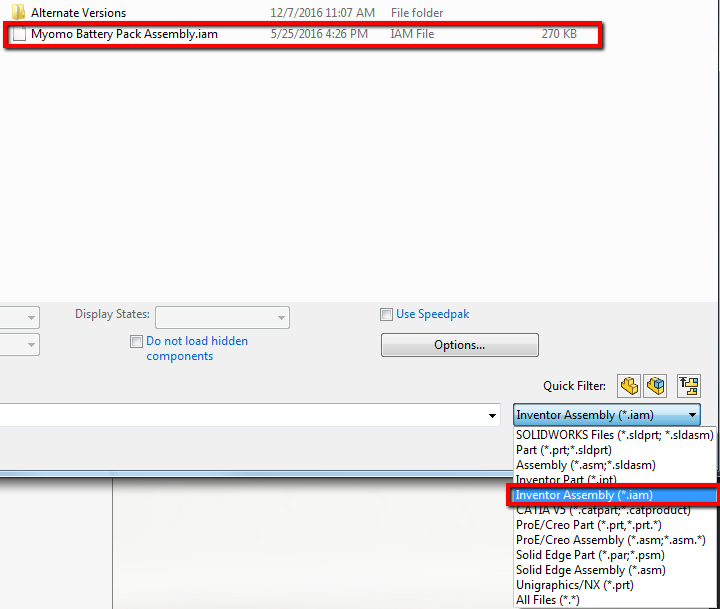

One of the main ways we see our customers utilize 3D Interconnect is directly

importing an assembly or part file from their 3rd party CAD data

right into their SOLIDWORKS assembly. SOLIDWORKS has simplified the workflow

down to just doing an ‘Insert Component’ and either selecting ‘All Files’ as

the ‘File Type’ to show or the specific file type you’re looking for. In this

case, we’ll bring in an AUTODESK Inventor Assembly file (.iam)

|

Afterward, we’ll see this ‘Open Progress’ dialog box to tell us SOLIDWORKS is

reading the model.

|

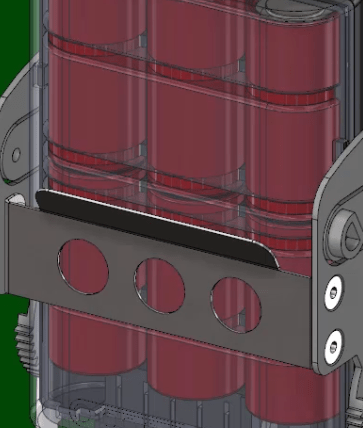

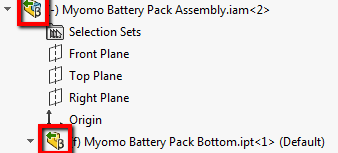

Once brought in, we can see the FeatureManager will include a green arrow on

the assembly and part icons to indicate it was imported from a 3rd

party CAD program.

|

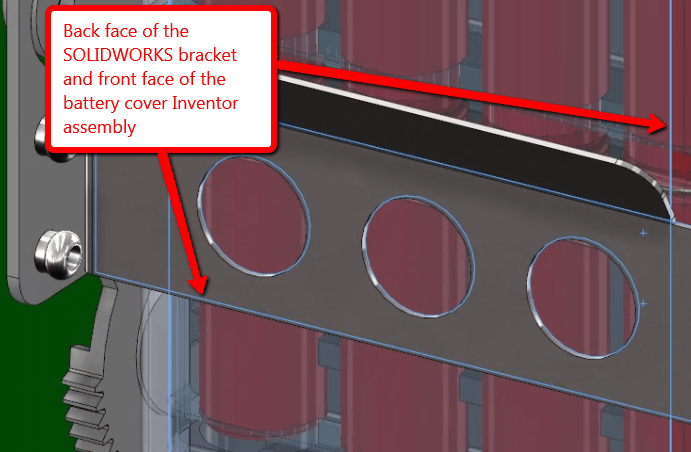

From here, we can treat the Inventor assembly like any other SOLIDWORKS

assembly by creating mates to the existing SOLIDWORKS geometry to properly

place the battery pack into position.

|

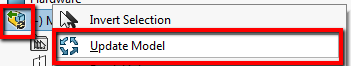

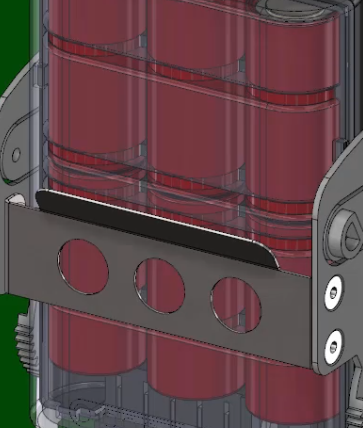

Now, say a different version of the battery pack has been created in Inventor

and we want to utilize that in our SOLIDWORKS assembly, while still preserving

all the assembly mates we used to position it. It’s almost as easy as

importing it in! First, you’ll want to overwrite the existing Inventor

assembly through Windows Explorer. After doing so, if you take a look at your

FeatureManager tree, we’ll see a small refresh icon by the assembly icon. To

update the model, we’ll simply right click and select ‘Update Model’. The

mates will update automatically to correspond to the new geometry!

|

By utilizing this workflow, we can open propriety 3D CAD data directly into

SOLIDWORKS while retaining associativity to the original file! This allows

you, as the engineer or designer, to work more seamlessly with your other CAD

data! Stay tuned for Part 2 of the 3-part series where we’ll explore how 3D

Interconnect can integrate CREO files into our SOLIDWORKS assembly!

|

For more information, check out our

YouTube channel

or contact us at

Hawk Ridge Systems

today. Thanks for reading!