Learn How SOLIDWORKS Plastics and SOLIDWORKS Simulation Work Together

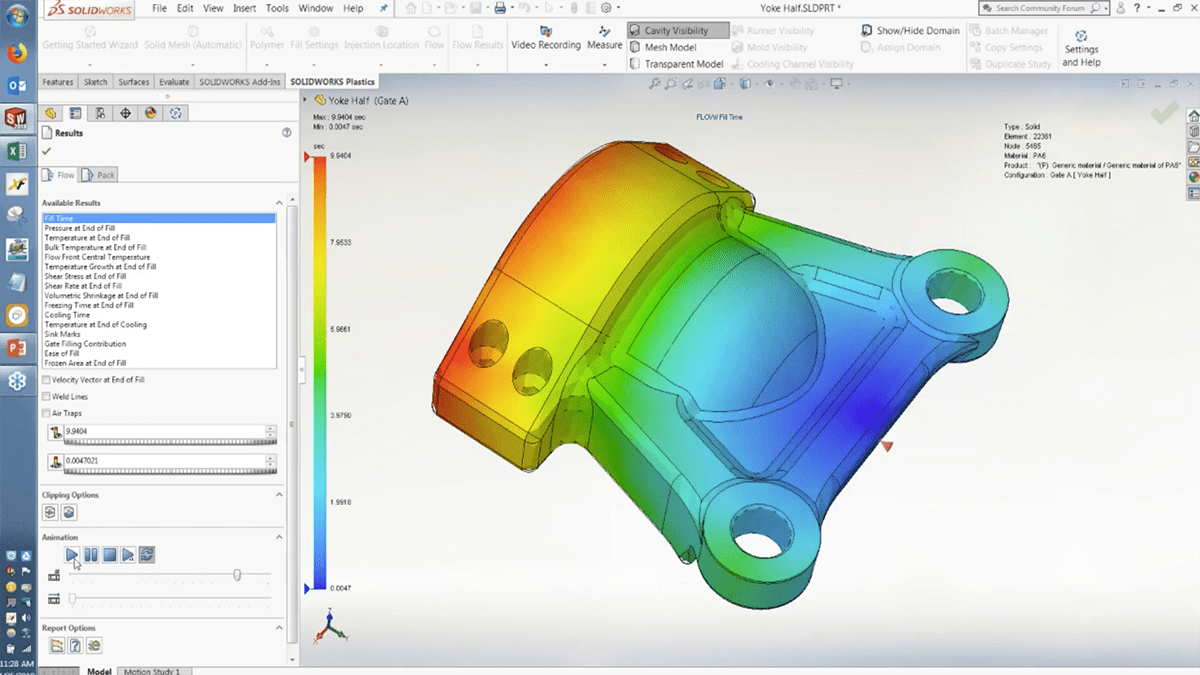

If manufacturing strong plastic injection-molded parts is a key part of your business, you won’t want to miss this webinar recording. While the design of a mold tool has a big impact on the manufacturing process, it can also be a key contributor to costly failures in the field. Join Product Manager, Damon Tordini, for a look at an integrated process where potential weaknesses in a plastic part can be identified with a nonlinear stress analysis using SOLIDWORKS Simulation Premium by incorporating data from the molding process via SOLIDWORKS Plastics. Find out how these two tools work together to improve the quality of your design, saving you both time and money.

Learn more about SOLIDWORKS Simulation and SOLIDWORKS Plastics or CONTACT US today.