Whenever multiple components are to be analyzed in a SOLIDWORKS Simulation

study, contact interactions become a concern. SOLIDWORKS Simulation has some

great ways of automatically defining contact, and also to the ability to

visualize the existing contact interactions.

The Contact Visualization Plot is one method that makes it very easy to

identify the contact sets that are being used in the study and the faces they

are defined between. What actually happens behind the scenes in any of these

contact interactions is that “contact” or “gap” elements are incorporated into

the mesh at these locations.

In most practical situations it’s not necessary to be too concerned about the

contact elements behind the scenes, which is part of the reason they are not

obvious to the end user. But the contact elements are the reason you may have

noticed your mesh becomes “out of date” any contact conditions are modified.

Consider the rest of this article and companion video for more background

information or academic understanding of the contact interactions, than any

practical guidelines.

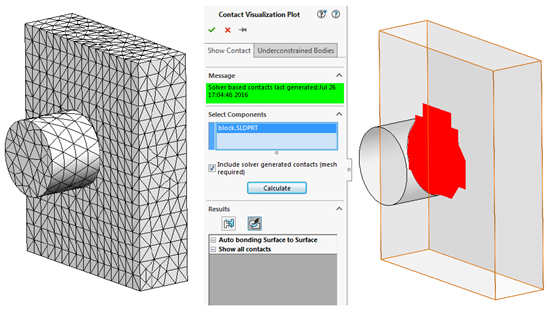

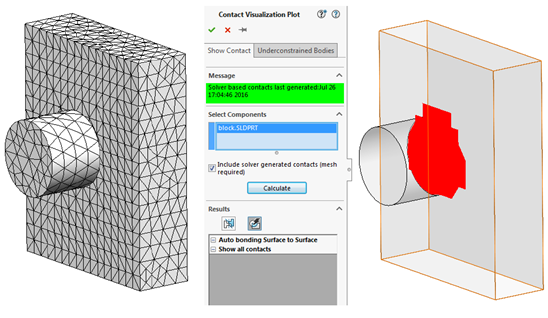

A lesser-known option within the Contact Visualize Plot to “include solver

generated contacts” allows the user to gain some insight into the actual

contact elements being placed. In the image below you can see a cylinder

separated from a plate by a gap. In this example, a bonded contact has been

manually enforced across the gap.

|

It’s a general recommendation not to bond across large gaps, and to treat

carefully anytime you do need to bond across a gap. In the image above we can

see some evidence of why (in this example the mesh is also fairly coarse to

exaggerate the effect) as the face of the cylinder needs to be projected onto

the plate to estimate where the contact should occur. Note: The user must

click on the “Auto Bonding Surface to Surface” result to see this effect after

calculating the solver generated contacts.

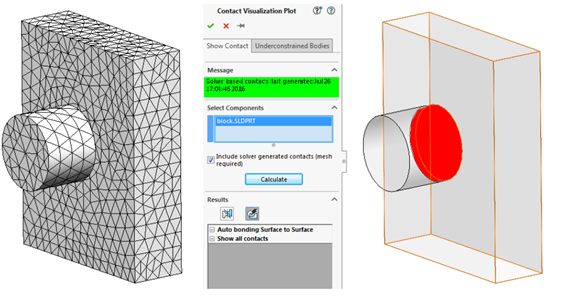

A similar recommendation is to use Split Lines to create a separate face for

situations such as this. Typically if the two components were touching, a

“compatible” or node to node mesh would automatically be enforced at their

interface which would ensure the nodes of the mesh on the plate line up with

those of the cylinder. This can be approximated somewhat manually by using a

Split Line to split the face of the plate, in the area where the cylinder

would imprint- as evidenced by the resulting solver-generated contacts with

the Split Line below.

|

In any case, using the Contact Visualization Plot with the option for

including solver generated contacts provides the most possible information we

can extract from the software about the contact interactions that take place

behind the scenes.

For additional details on how this process can be performed, please check

out our

YouTube channel

or contact

Hawk Ridge Systems

today. Thanks for reading!