Fall is always a great time of year. Football is in full swing, the World

Series is around the corner, there will be snow in the mountains soon, and, of

course, new features in SOLIDWORKS Simulation are unveiled.

This year,

SOLIDWORKS 2015

has a new tool called Shell Manager which will drastically reduce the time it

takes to define shells and simplify the modification of them in your next

simulation.

Shells are ideal for the analysis of high aspect ratio parts such as sheet

metal or components with one dimension, the thickness, significant smaller

than the other two. It seems like just yesterday that SOLIDWORKS 2013 provided

the ability to Render Shell Thickness in 3D, improving the visualization of

results during post-processing. Earlier this year ilyn our blog

Render Shell Thickness in SOLIDWORKS Simulation, we discussed this enhancement as well as some basics of using shell

elements in an analysis, a nice resource to review if needed. If you have

already been using shells, or perhaps found them too tedious to setup in an

analysis you will want to read on to learn more about the Shell Manager.

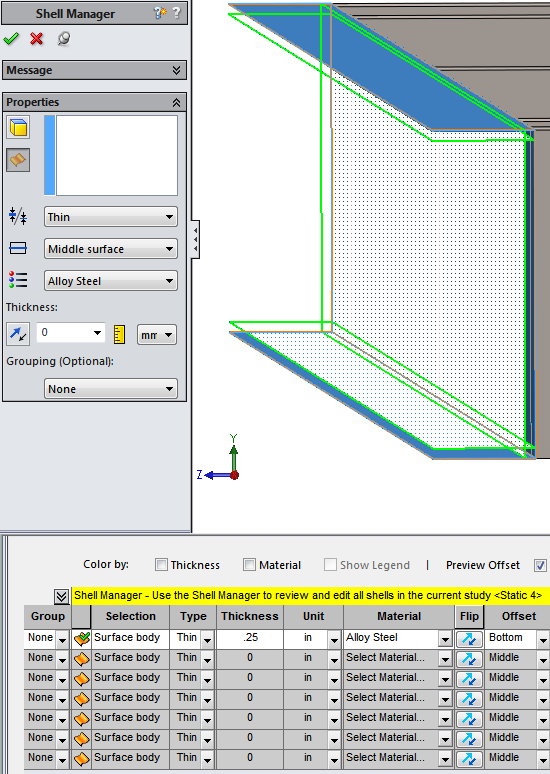

I will be using the Shell Manager anytime I have more than a couple of shells

in an analysis. The on-screen feedback and single location to control many

properties of my shell definition is a welcome change from having to select

each shell individually if changes are required. Now, I only have to right

click on a body or previously defined shell in the Simulation Tree and choose

to access the Shell Manager tool. I can enter and/or modify the definition

using the property manager or I can input parameters in tabular form at the

bottom of the screen. All of the same shell definitions are available through

the new tool such as type, thickness, and offset, but now I can also easily

define the material in the same interface.

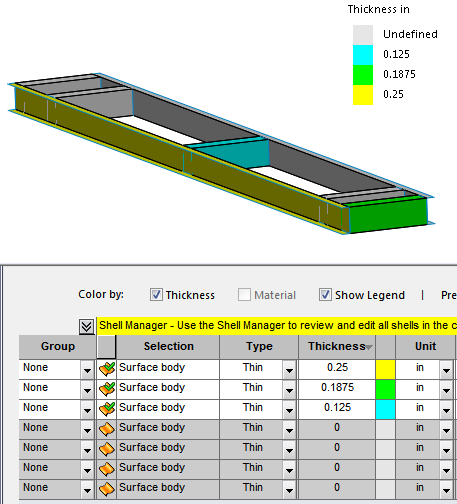

As I create more and more shells in my model, I can always check to ensure my

definitions are accurate using the Shell Manager. The Preview Offset allows me

to verify that the shells accurately represent my 3D model, while the “Color

by:” choices of “Thickness” and “Material” allow for on-screen visual feedback

to show which material is used on which shells or if all of my cross-member

shells are the proper thickness.

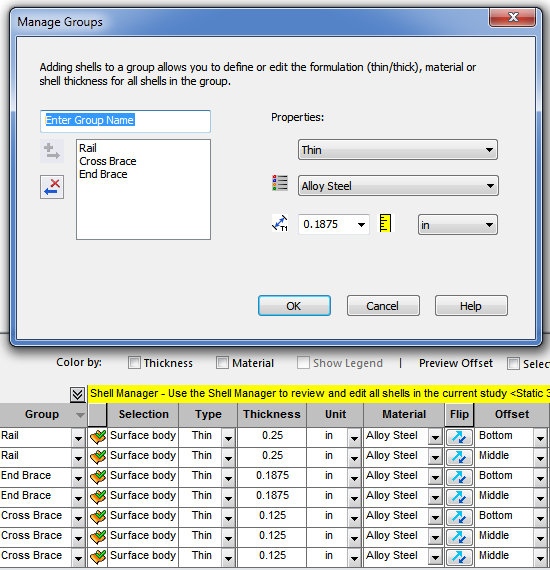

The increased feedback and input options are great during shell definition,

but the real time-saver is when I have design changes that I want to quickly

implement in my analysis. I can now group shells with the same definition

together using Shell Groups. This provides one location where I can change the

type, material, and thickness of multiple shells with one dialogue box instead

of modifying each individual shell. In my example, I have 3 Shell Groups to

modify instead of the 7 individual shells – imagine the time-savings if I had

30 shells in my model that are now in just 3 Shell Groups. An awesome

efficiency improvement for SOLIDWORKS Simulation 2015. Bring on the design

changes, I am ready!

I’ll be showing new features like this at our SOLIDWORKS 2015 Launch events in

Las Vegas, Reno, Northern California,

Southern California, Portland, and Seattle in just a few weeks. Join me and the rest of Team Hawk Ridge for the Launch

event, which includes a networking hour with drinks, food, and prizes. My

counterparts in Canada will visit

Winnipeg, Toronto, Vancouver, Saskatoon, Calgary, and Edmonton. Click on the location nearest you for more details.

Also, please keep an eye on our YouTube channel for an upcoming video demonstrating this new tool and other enhancements for

SOLIDWORKS 2015 as well as great tips and tricks for all of the SOLIDWORKS

Products.