When you come to a sheet metal part with an odd shaped or partial edge flange

you might realize that the usual select and size approach it not going to

work. You are stuck trying to decide if you should just use a normal

rectangular edge flange and then cut away the excess and drill a hole or

attempt to use that mysterious Edit Flange Profile button, if you have been

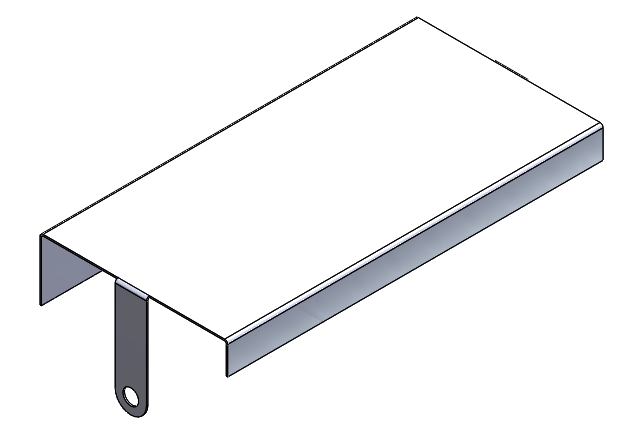

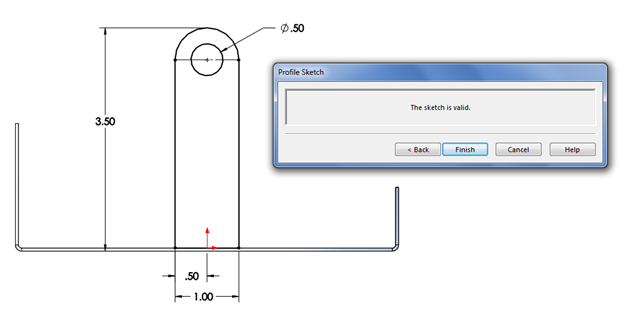

alert enough to notice it by now. What is the difference? As you can see in

the example part below, the resulting geometry is the same and they will both

give you the same flat pattern. Why should you use one over the other?

Edited Flange Profile

To make sure we are all on the same page, let’s take a look at how I got to

this point from both approaches.

Method 1: Normal Edge Flange and Cut

I am going to assume you can figure out how to get the Base Flange and first

set of Edge Flanges, so we will fast forward to the point where we need to add

the unique flange. First, I am going to select the edge I want to apply the

flange to and select the Edge Flange command from my Sheet

Metal Command Manager. (Yes, you can select the edge after you invoke the

command but why wait? Time is precious!) Next, I need to click in the

direction and approximate size for my new flange. Finally, I dial in my exact

desired dimension and now, we have the oversized start of our flange.

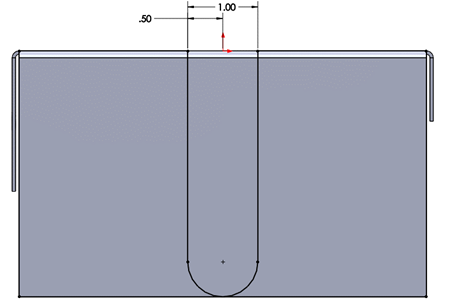

Next up is the cut in order to trim it down to the size I am really after. I

make a sketch on the face of the flange and convert the top and bottom edges,

draw in a couple lines and an arc to designate the areas I want removed.

With that sketch, all you need to do is perform a

Cut Extrude to the vertex of the bend and your part is

looking better already.

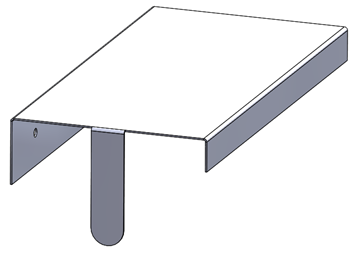

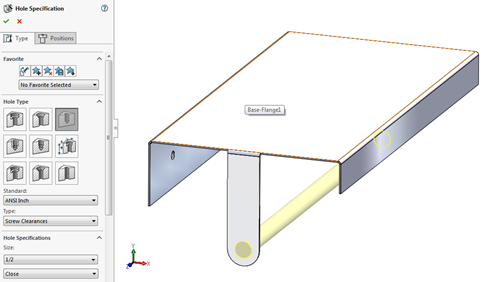

The last feature we need for this approach is a hole, let’s bring on that

wizard. By clicking Features > Hole Wizard, I set the size

to my specifications and place it concentric with the arc accordingly.

So there you have it, three steps later and we have made our boss so very

proud of the little designer we have become. Now let’s explore the option you

will probably use going forward.

Method 2: Edit Flange Profile

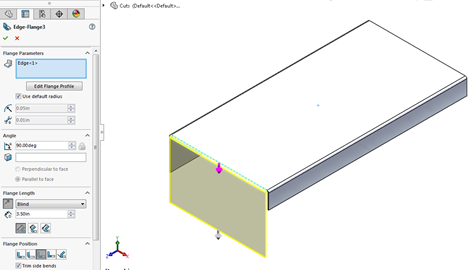

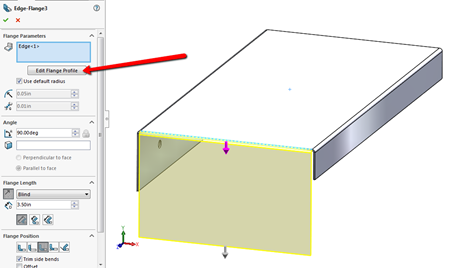

Again, starting with our Base and Edge Flanges, we are going to use the same

first step as above. Select the edge and click on the Edge Flange command. Go

ahead and make that second click to place the flange in the appropriate

direction. Now, we are going to deviate from our first method. Before you give

your flange a real dimension, go ahead and click on the Edit Flange Profile

option. [Cue Twilight Zone Theme Song]

You should now be looking at a plane old boring rectangular sketch; in 2015

and newer that is, all previous versions would show a single line to define

the length of the edge flange. You are probably thinking, “Okay, now I just

modify the sketch,” and you would be correct. The Edit Flange Profile option

gives us the chance to sketch in the real profile of our edge flange and skip

all that rectangle with cuts non-sense. We modify the sketch to look like the

inverse of our sketch in the previous method, and we can even go so far as to

include the hole right inside our profile. That’s right, it’s a contour within

a contour. With the Edit Flange Profile option, really all you need is some

sort of closed contour that uses a portion of the edge it will be bent from.

Then you can get as creative as you want with the design or internal contours.

The profile sketch pop-up will let you know if what you have sketched is going

to work for an Edge Flange.

With the click of the Finish button, we have the same

geometry as before in a third of the steps.

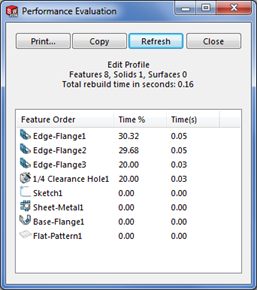

Try all you want, and run all the utilities you can, these two parts will be

geometrically identical. Flatten them, they will have the same the exact same

flat pattern. Why should you learn this way of doing your design instead of

the old faithful cut? Time! Why waste time doing extra steps to add the cut

and hole when you can do it all from the Edge Flange command?

You CSWP types are probably thinking, “Hey, I can do the cut and the hole in a

single multi-contour cut, so are you really saving me time?” Thank you for

asking, and yes, I still am. Not only do you get to skip the cut step itself

saving design time, but I am also saving you rebuild time. Go to your

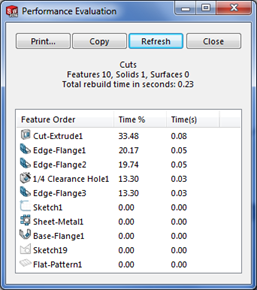

Evaluate tab > Performance Evaluation.

Sure enough, the Cut Extrude accounts for 33.48% of the rebuild time.

With Cut

Sure, that only adds up to 0.08 seconds which is less than a blink, but this

is only one simple part. Let’s say this part is 1 of 1000 in a larger

assembly. Do you really want to spend over a minute each time that assembly

rebuilds thinking, “He told me so”? If you don’t just design simple paper

towel racks, your designs probably have more than one such tab on it. Now, we

might be talking even more time to think about your actions.

Ultimately, the choice is yours as to how you would build this part. Both ways

produce a valid part that manufacturing will be able to build to your

specification. However, it is clear that simplifying your tree by using the

Edit Flange Profile over an extra

Cut Extrude not only makes you look more proficient, it makes

your designs more efficient.