Aircraft seat assembly ready for nesting and machining

With the markets ebbing and flowing, talks of fiscal cliff deals, and the

lessons learned from the past few years, it seems the age old adage of “time

is money” has never rung so true. Whether it’s honing your systems and

procedures using data management tools, sharpening your modeling skills by

taking a class, or optimizing your products using finite element analysis, the

focus on productivity and streamlining is apparent in many areas of business.

But what happens when the design gets approved and released for production?

Productivity has always been a priority of any machine shop; maximizing the

use of the stock, minimizing the cycle time and managing waste are just a few

examples – but what tools are available to assist?

For maximizing the use of stock material and minimizing waste, there are a

variety of nesting packages available. Many are predominantly geared towards

the sheet metal market; as such they use a DXF format to adjust the

orientation of the flat pattern. Other packages use a block nesting approach

for 3D files whereby an imaginary rectangle is fitted to the part as closely

as possible resulting in a quick nest but not an optimal solution from a waste

perspective.

CAMWorks

Nesting is a true-shape nesting program that creates fast and efficient nested

layouts of 2D flat patterns and 3D parts. Being the first CAM gold partner

for SolidWorks has its advantages also. The program allows you to use either

SolidWorks files or imported geometry (such as Parasolid, STEP, IGES etc), in either

part or assembly format and works with multi-body parts (a commonly used

modelling practice for sheet metal and welded components).

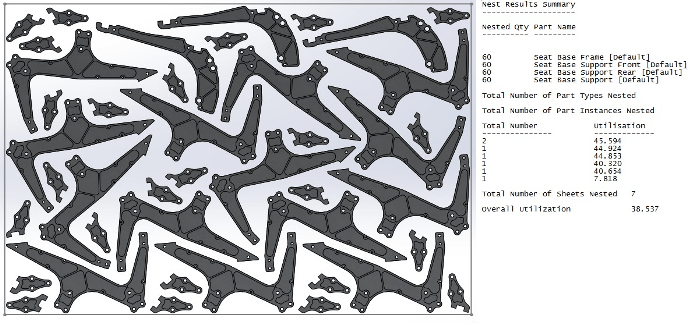

A fast nest solution showing room for improvement, but still well nested.

Have a tight deadline? You can choose to run a fast nesting process which will

quickly create a nest of the parts but may not be the optimal nest. Machining

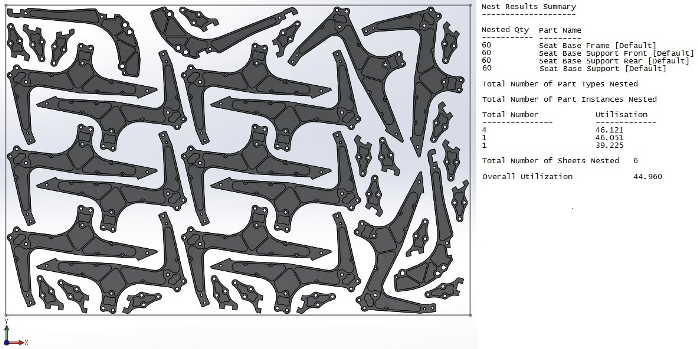

that expensive Inconel? You can also choose to optimize the nest and it will

produce an assembly of well nested components so you’re not giving your

profits away to the swarf recycler. And for those that are down to the wire

but need the best efficiency, you can set a time constraint for optimization.

Optimization has managed to increase the material utilization by nearly 7%

So you’ve set everything up, ran the nesting, got a great looking nested

assembly and just as you’re about to hit the big green button the customer

calls saying they need to make a change! It’s usually at 4:59pm and the job’s

got to be running. Not to worry! You can either make the changes to the

SolidWorks file or update the imported file and rebuild the nest. The nesting

will update to accommodate the changes to the file.

Need to machine your parts? Use all the benefits of CAMWorks – a true

feature-based, parametric CAM tool, right inside of the nested assembly. The

key time-saver here is the automatic feature recognition (AFR). The speed at

which it can detect features such as pockets, holes, and bosses, associate

machining operations to the features, and generate the toolpath is

mind-boggling at times. But one of the greatest assets is the ability to teach

it the way you machine your components. That one click

button to program your parts isn’t so much a dream – with CAMWorks it can be

your reality!

The greatness of CAMWorks is not just about the tools themselves; it’s the

support we can offer. Our dedicated support team is second-to-none, and has

the can-do attitude it takes to get to the bottom of any question quickly and

efficiently so that you can be productive. Hawk Ridge Systems employs a number

of engineers with CNC experience, and because of that we will be able to

relate and relay this information to ensure that our software and support

continues to be the best.

See CAMWorks in action –

Watch this video.

If you’d like to find out more information about CAMWorks or request a

demonstration, please give us a call at 877.266.4469 in the US or 866-587-6803

in Canada, or email us at [email protected]. You can also check out our

Webinar Wednesday schedule

for upcoming CAMWorks eDemos!