When I mention the word “multibody”, I hope it doesn’t bring up the bowling

dream sequence in The Big Lebowski because that’s an out-of-body experience. A

multibody part is a part in SOLIDWORKS that is made up of multiple solids

and/or surfaces within the same part file. These bodies can be touching or not

touching, but if they aren’t touching, then they are separate bodies by

default. You can make multibody parts using various modules within SOLIDWORKS,

but this article will focus on creating multibody sheet metal parts within the

sheet metal module.

Making a multibody sheet metal part is easy and useful. Some reasons you would

make this type of part is if you are working with different gauges and

different materials of sheet metal within the same part. Also, if the bodies

are within the same part, if you change a dimension or relation of one part,

everything will change accordingly. This insures that your parts fit together

when you are done with your design.

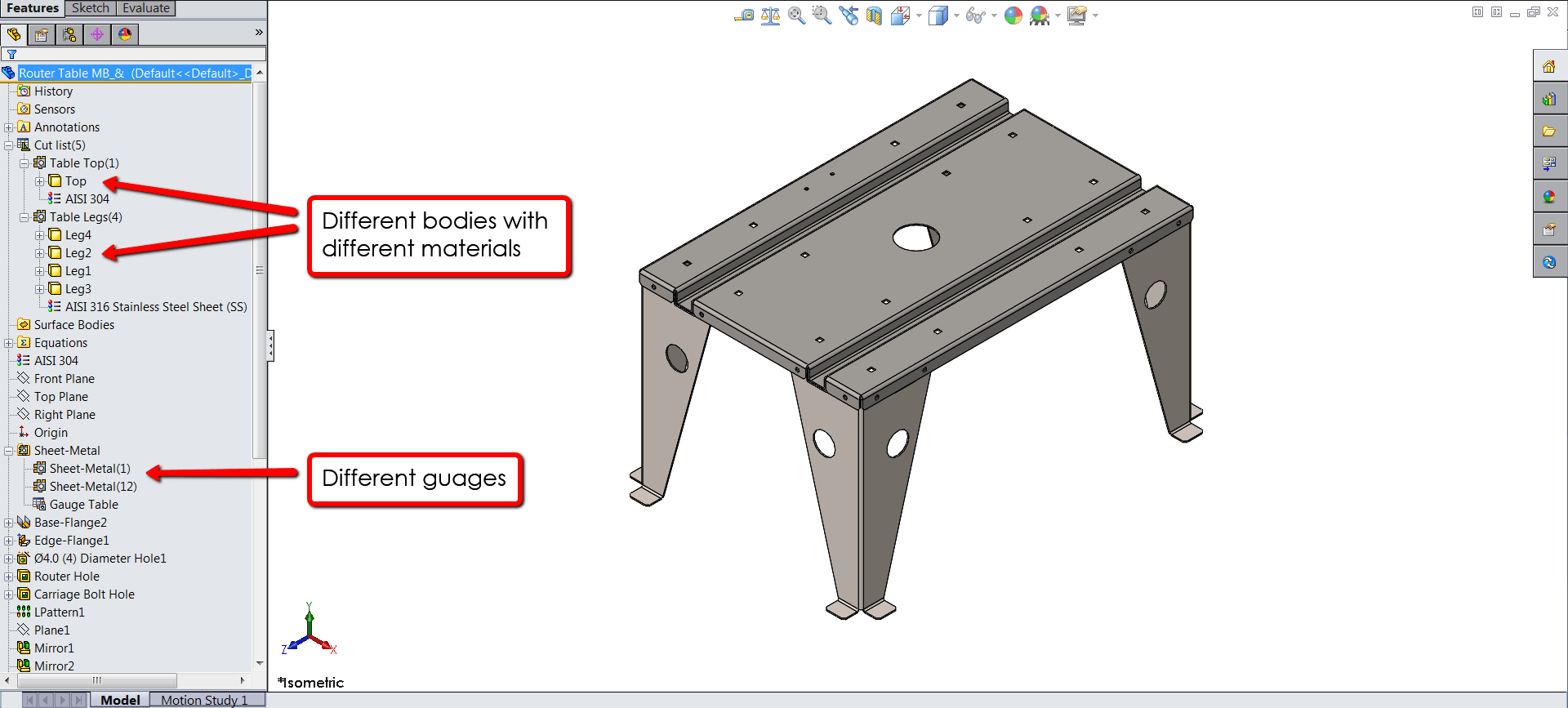

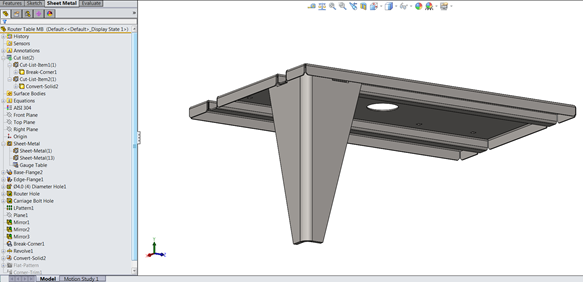

Here’s an example of what a multibody sheet metal part looks like. This is a

router table with a top and 4 legs:

In this example, the router table is AISI 304 material while the legs are AISI

306. Also, the legs and the table top are different gauges. Let’s step through

how you would create a part like this.

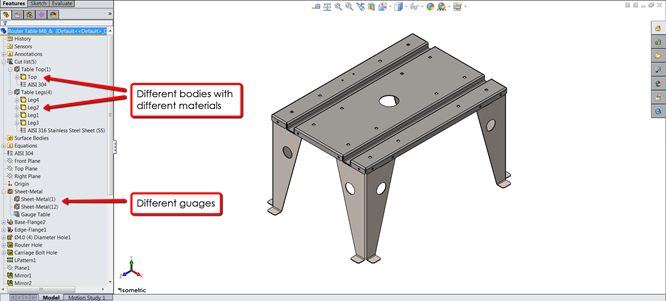

I’m going to start at the step where the table top was created as a single

body. To summarize, this was created as a profile sketch, extruded as a Base

Flange/Tab, and then Edge Flanges were added to the sides. There’s also some

holes added to the part:

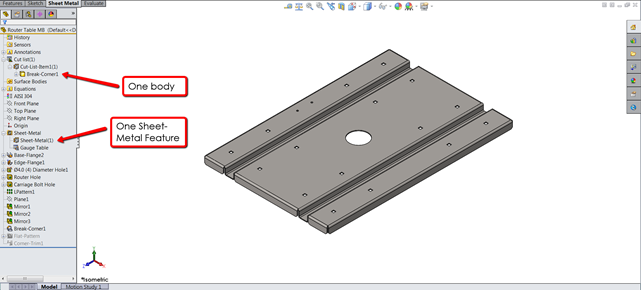

From the feature manager tree, we can see that there is one body in the Cut

list, and one sheet-metal feature, as expected since this is a single body

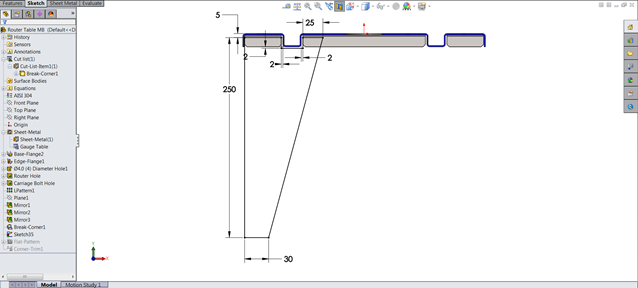

part. I’m going to start a sketch on one of the inside faces that will be the

profile of one of the legs:

Note that the view has been sectioned so that we can make dimensions and

relations to the profile of the table. Now I will revolve the profile about

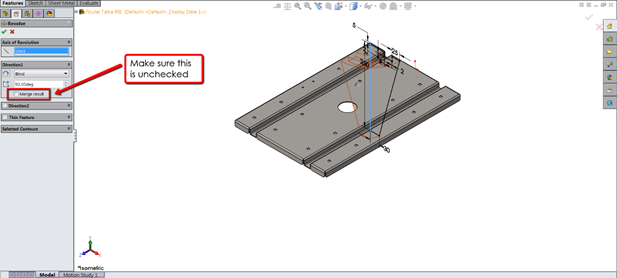

the long side 90 degrees:

By default, SOLIDWORKS will want to merge this new feature with the table top

since they are touching (remember the first paragraph of this article?) I

don’t want it to do this since I want a separate body, so make sure that the

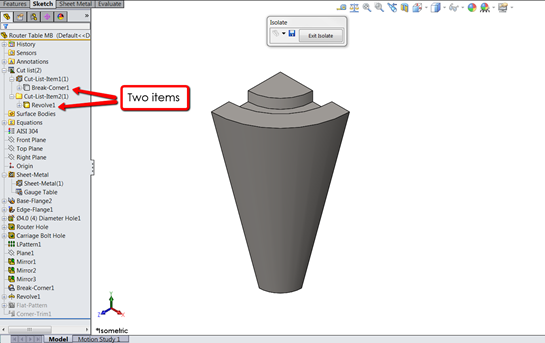

Merge result box is unchecked. Now if we look at the Cut list folder, there

are 2 bodies. I can also isolate the body I want to work on by right clicking

the name in the Cut list folder and clicking Isolate:

The icons are different since the first body is a sheet metal body and the

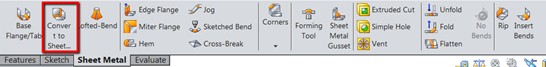

second body is a solid body. Next, we convert the solid leg to sheet metal by

clicking the Convert to Sheet Metal button:

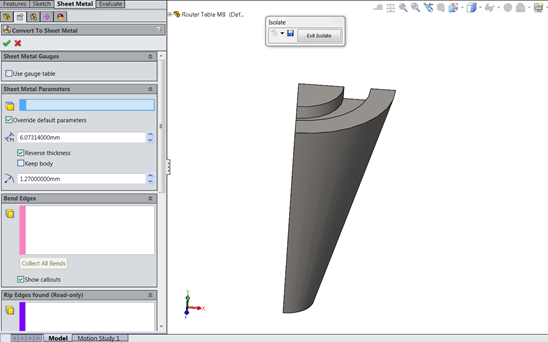

At this point, we can choose to use the same gauge as the table or change

At this point, we can choose to use the same gauge as the table or change

it:

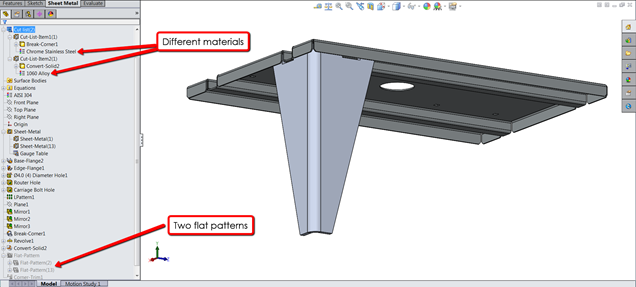

After the conversion and exiting the Isolate, we now have two separate pieces:

We can add different materials to each (right click on the body in the Cut

list, and if you look down at the bottom of the Feature Manager tree, you can

see we have two separate flat patterns:

If you hit the Flatten button in the Command Manager, it will

only flatten the first body, so you will need to actually unsuppress the flat

pattern feature for the other body, or right click on the body and select

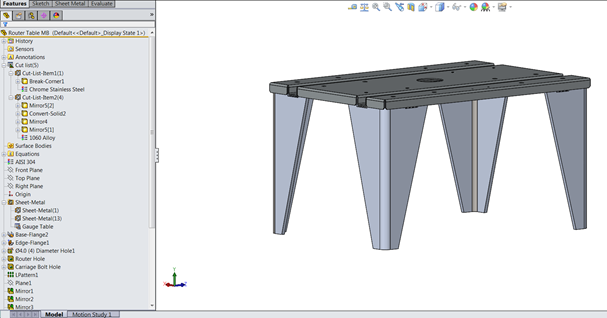

Flatten. Now with a couple of

Mirror operations, we can use that first leg to create 3 more

legs. SOLIDWORKS might add these bodies to a new Cut list, so just select them

and left click and drag them into the Cut list you want them to be in.

That’s it! If you would like to see a video on this, please click on this link. Good luck on your sheet metal designs and thanks for reading!