Managing contacts is something that comes up constantly when working on

customer projects in

SOLIDWORKS Simulation. I recently had a project that involved a large and complex assembly with

numerous contacts to be defined. There were three things I was concerned about

when trying to plan, setup, and review contacts in the analysis:

- Where contact will have to be defined manually between faces and components

- What type of contact is used and which faces/components were selected

-

To make sure that a no penetration contact was defined between the correct

components

There were three tools and plots in SOLIDWORKS and SOLIDWORKS Simulation that

I used to visualize and check the contacts in my analysis: Interference

Detection, Contact Visualization Plot, and Contact Pressure Plots. Let’s take

a brief look at how each of these work.

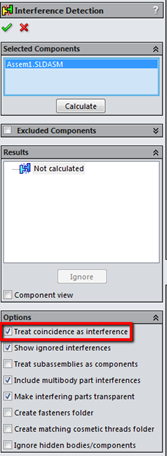

Interference Detection

In SOLIDWORKS Simulation, the global component contact will automatically

apply the specified contact condition to all faces that are initially

touching. To help see which faces will be used, there is a tool within

SOLIDWORKS

called Interference Detection. To use it, start by going to

Tools > Interference Detection. This is

where you can enable the option to “Treat coincidence as interference”.

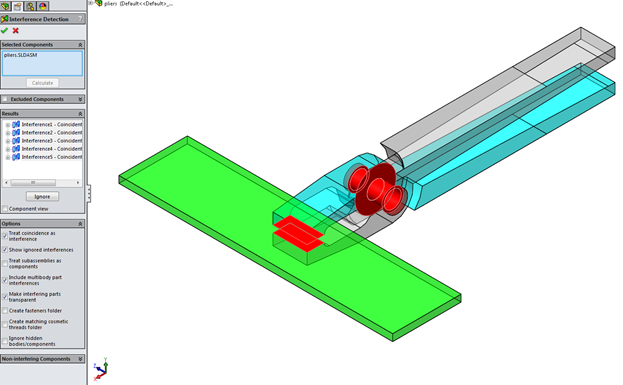

Under the results section, there will be a list of all the initially touching

faces. Clicking on a result will highlight the touching faces in red as in the

screenshot below. Don’t forget to enable the options to “Show ignored interferences”

and “Include multibody part interferences”.

The Interference Detection Results Show Coincident Faces Highlighted in

Red

Bonus Tip: This tool is also one of the

four tools I use before running my analysis. As the name suggest, interference between components can be found by not

enabling the “Treat coincidence as interference” option. Removing

interferences will help prevent problems when trying to mesh and solve an

analysis.

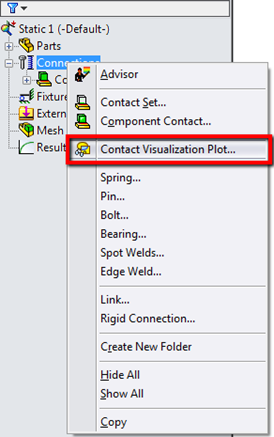

Contact Visualization Plot

Starting with SOLIDWORKS Simulation 2014, visualization plots can be created

to help visualize the type of contact and the faces/components that are used.

To create a contact visualization plot, right-click the

Connections folder in the Simulation tree and choose “Contact Visualization Plot”.

After clicking Calculate, the results section will show all

the contacts that have been defined along with, whether it is a global contact

or contact set and the type of contact. Selecting an item in the results will

use a particular color, based on the type of contact that is defined, to

highlight the face in the graphics area. Below is a table of the types of

contact and associated colors that are used:

| Contact Type | Color Rendering |

|

Bonded |

Red |

|

No Penetration |

Purple |

|

Allow Penetration (Free Contact) |

Green |

|

Shrink Fit |

Orange |

|

Virtual Wall |

Yellow |

|

Thermal Contact Resistance |

Purple |

|

Insulated |

Green |

Contact Visualization Results Highlight Contacting Faces Based On Type

Contact Pressure Plots

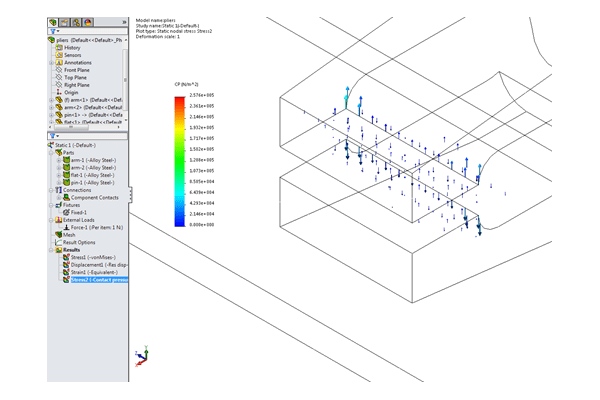

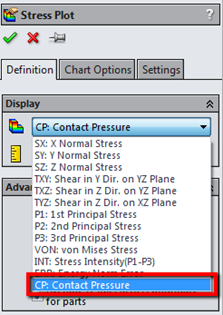

In SOLIDWORKS Simulation, a useful plot to help see if there is a no

penetration contact defined between components is a contact pressure plot.

Contact pressure is the result of two bodies coming into contact during an

analysis with a no penetration contact defined between them. To create a

contact pressure plot, define a Stress Plot by right-clicking

the Results folder from the Simulation tree.

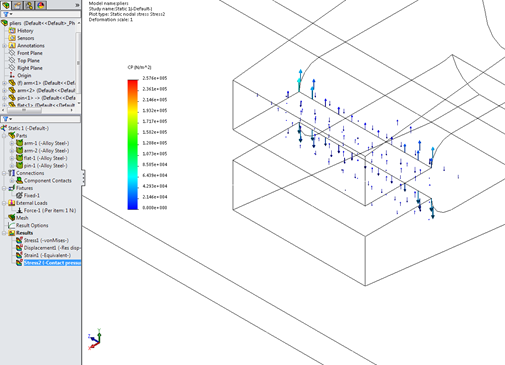

The plot that is generated can either be a vector plot that shows contact

pressure between all components or a color plot that shows contact pressure

between selected components. Starting with SOLIDWORKS Simulation 2014, contact

pressure plots can also be created in a 2D simplification analysis.

Contact Pressure Result Shown As A Vector Plot Between Faces With No

Penetration Contact

Hopefully these tools can help you setup contacts more quickly and

efficiently. To learn more about these features and tools, I encourage you to

look at the SOLIDWORKS and SOLIDWORKS Simulation Help. Also, if you have your

own tips and tricks for handling contact in an analysis, please share them in

the comments section below.