Since the advent of

Since the advent of

CAD software

in the design and engineering world, one of the main advantages touted by

developers and users has been the ability to check for errors and mistakes

during the design process. Discovering and fixing design flaws, honest

mistakes, and little bugs before a product reaches the production

phase – not to mention consumers – is an obvious way for a company to reduce

costs, waste, and protect themselves both from lawsuits and a bad reputation.

There is almost no disputing the fact that computers scanning for and

rectifying human mistakes during the design process has led to an overall

improvement in the general quality of the products we use in the world today,

and major savings for the companies that make those products.

SOLIDWORKS Electrical is no exception to this trend in engineering CAD

software. There’s an obvious need to be able to rapidly scan and check

electrical project documents for accuracy, completeness, and informational

clarity: with potentially thousands of wires going to dozens or hundreds of

components, it’s almost a statistical certainty that there will be

errors and small inconsistencies in the drawings and schematics.

SOLIDWORKS Electrical

takes care of this inherent problem by including several Design Rule Checks,

commonly referred to as DRCs. These DRCs scan the project for specific errors

and then provide a report on what those errors are and where they appear in

the project for a variety of different potential issues.

In this 5-part blog series, we’ll go in depth over four of the most commonly

In this 5-part blog series, we’ll go in depth over four of the most commonly

used SOLIDWORKS Electrical DRCs – what they are, how they work, and why you

would use them – on top of this introductory overview. These four DRCs are

also demonstrated in a 4-part YouTube video series. (Watch the first video

here.)

So, what exactly is a DRC and how does it work? A DRC is just a standard

report template that’s included with the software and designed to scan the

project for certain data criteria in the SQL database, then report back

anything that matches that criteria in the database in an easy-to-read format.

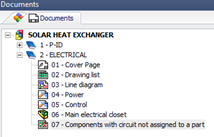

For example, if the DRC is selected to scan for Components without Part

assignments, the software will look through the Component list in the SQL

database and find any Components that do not have a manufacturer part assigned

to it, and then generate a table showing the Component tag and its location in

the schematics. This table document is then added in the master documents list

as a report; it can be saved as part of the revision and verification process

to include as documentation, or can be deleted once the errors are fixed.

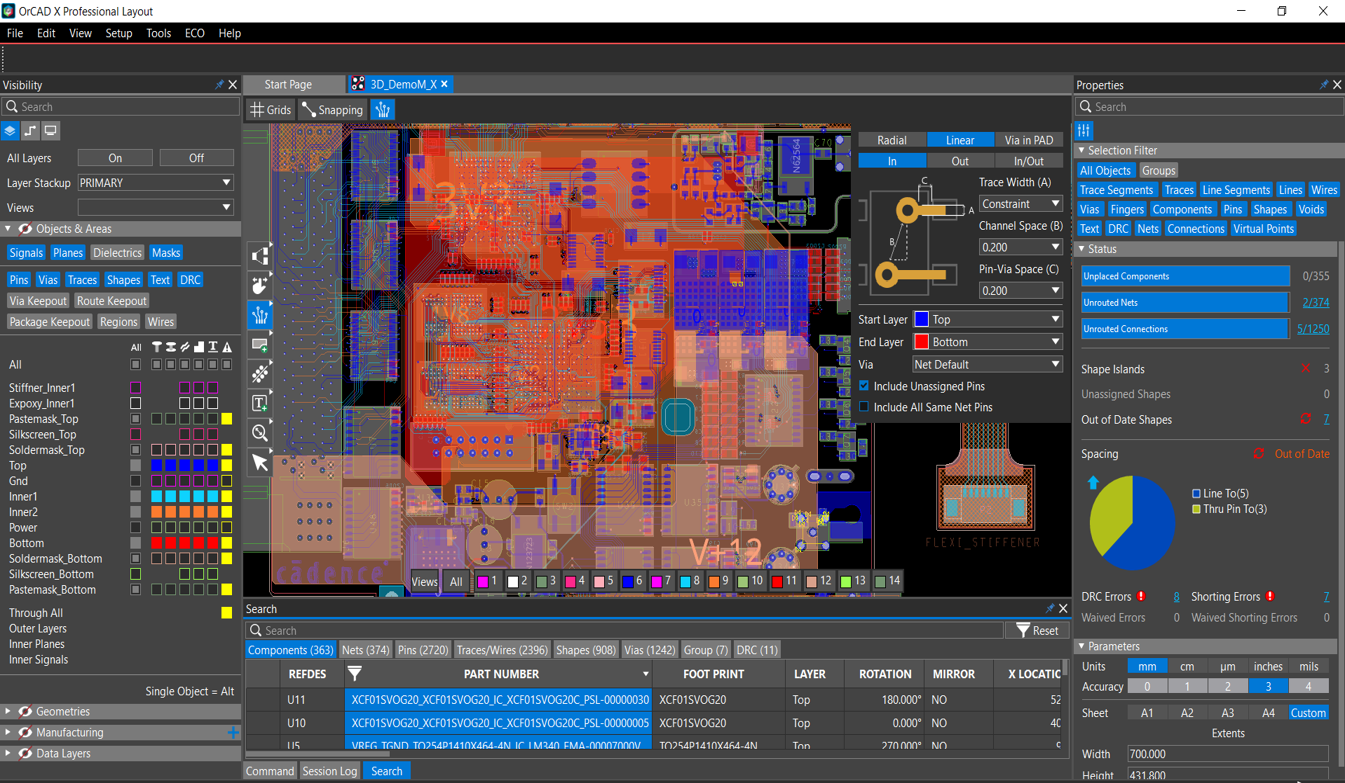

SOLIDWORKS Electrical, they can be accessed in the CommandManager in the

same location as Reports. To see the list of included DRC templates, click

on the Project tab and in the far right section titled

“Reports” is the Design Rule Check icon.

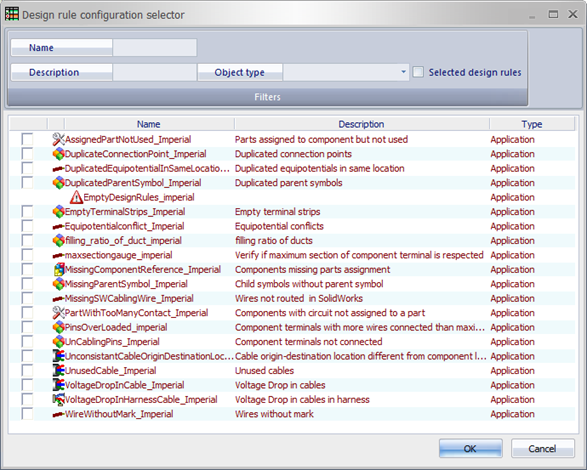

Click it and click Add in the upper left corner of the Design

Rules Manager window to see the master list of all the DRC templates included

with SOLIDWORKS Electrical.

To use any of the DRCs in the list, simply check the box next to the design

rule you’d like to implement and click OK; the software will

begin its scan of the project, and generate a report in the documents list if

any errors are found.

Be sure to check back for the follow-up blogs in this series, where take an

in-depth look at the Equipotential Conflict, Component Terminals Not

Connected, Components Missing Part Assignment, and Parts Assigned to Component

but Not Connected DRCs. For a visual demonstration, you can check out our

SOLIDWORKS Electrical series for Design Rule Checks on YouTube.