In this video and blog, we take a look at a conjugate heat transfer problem

with both convection and conduction using

SOLIDWORKS Flow Simulation.

Here are the steps used to set up the analysis.

Flow Simulation is a computational fluid dynamics (CFD) tool that operates

directly inside of SOLIDWORKS. You’ll need both

SOLIDWORKS and SOLIDWORKS Flow Simulation installed, with the Flow Simulation add-in

enabled, to follow along with this guide.

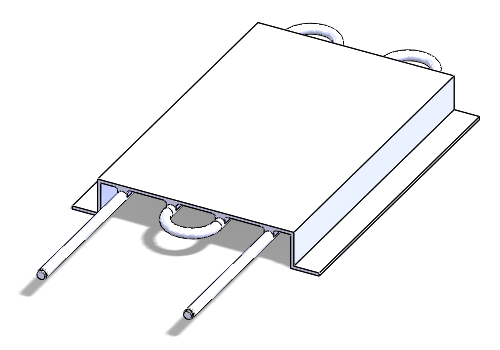

The first step is to get the geometry ready. For this cold plate, lids are

needed at both ends of the cooling tube. This allows the inside of the tube to

be defined as a separate internal fluid volume.

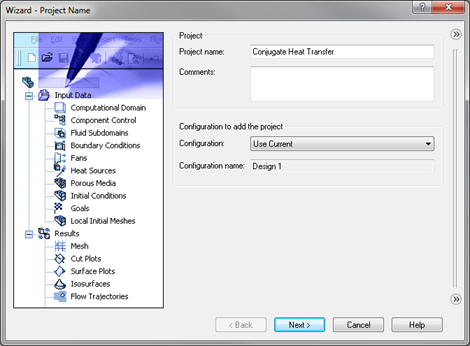

Next, I’ll create the Flow Simulation project using the Wizard. From the

Flow Simulation menu, I’ll select Project, Wizard. I’ll name the

project “Conjugate Heat Transfer” and choose to use the current configuration.

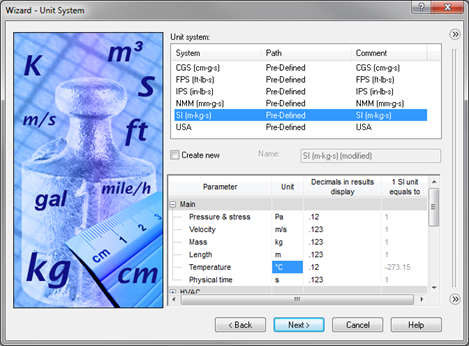

I’ll set my unit system as SI (m-kg-s) and change the unit for

temperature to °C.

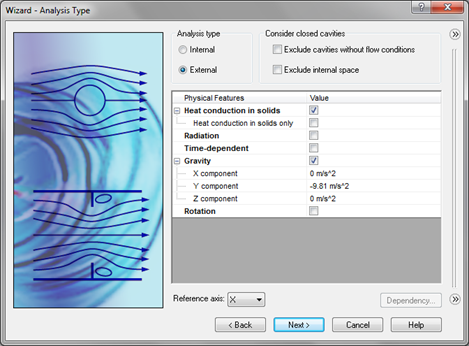

The analysis type is External because we want to consider the air

surrounding the model. I’ll turn on Heat conduction in solids and

Gravity, and confirm that Y component -9.81 m/s^2 is the correct

direction and value for this analysis.

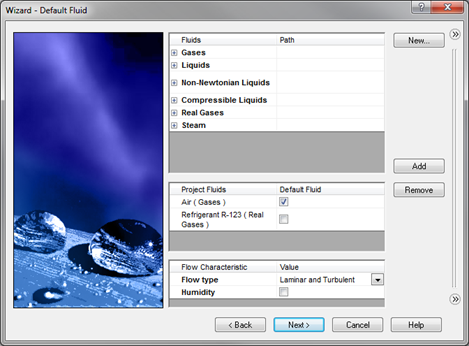

Air (Gases) and Refrigerant R-123 (Real Gases) are pre-defined

and can be added as the project fluids. I’ll make sure that the checkboxes are

set so that Air (Gases) is the Default Fluid.

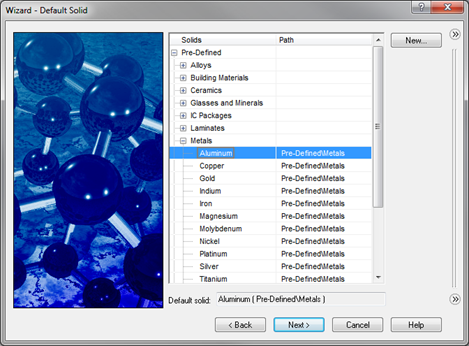

Aluminum is pre-defined under Metals and can be set as the

default solid.

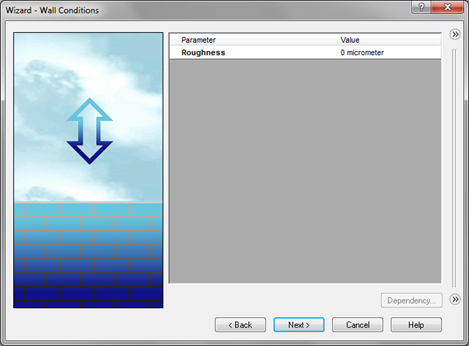

I can accept the default value of 0 micrometer for Roughness and

assume smooth walls.

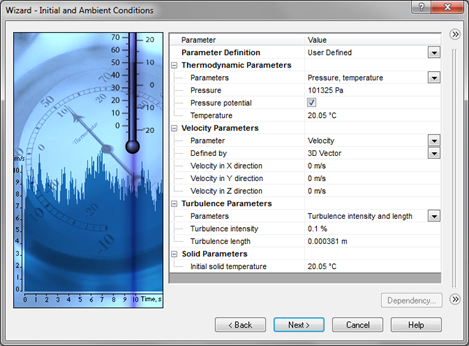

And I’ll accept the default values for the initial conditions.

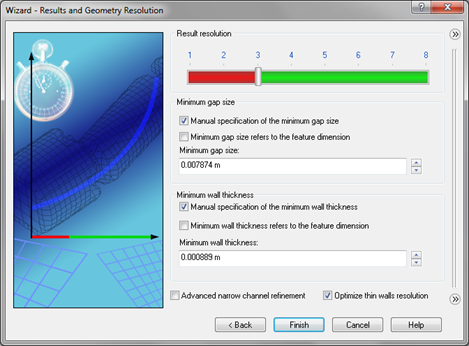

I’ll keep the Result resolution relatively low to start with and set it

to 3, and I’ll enter 0.007874 m for the

Minimum gap size and 0.000889 m for the

Minimum wall thickness, which correspond to the inner diameter and

thickness of the tube. I’ll click Finish and work my way down the Flow

Simulation analysis tree.

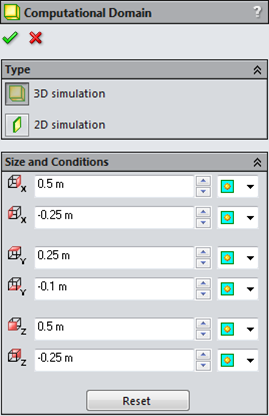

The automatically generated computational domain is bit larger than I need so

I’ll right-click Computational Domain, select Edit Definition,

and enter the following values.

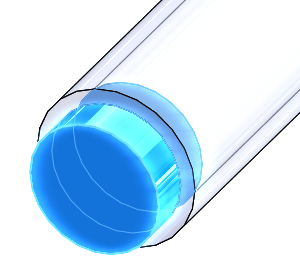

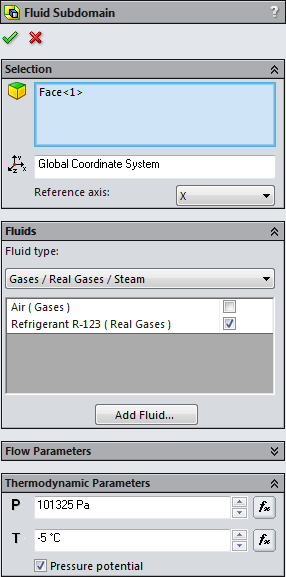

A fluid subdomain needs to be defined to set the fluid inside the tube as the

refrigerant. I’ll right-click Fluid Subdomains and select

Insert Fluid Subdomain. I’ll select an internal face of the tube, set

the checkbox next to Refrigerant R-123 (Real Gases), and enter

101325 Pa and -5 °C for the Thermodynamic Parameters.

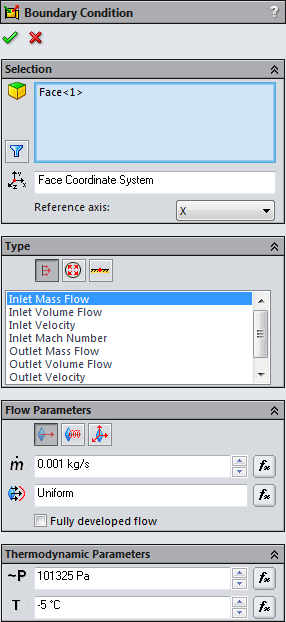

Next up are the boundary conditions. I’ll right-click

Boundary Conditions and select Insert Boundary Condition. I’ll

select the inner face of the inlet lid and define an

Inlet Mass Flow with the parameters shown below.

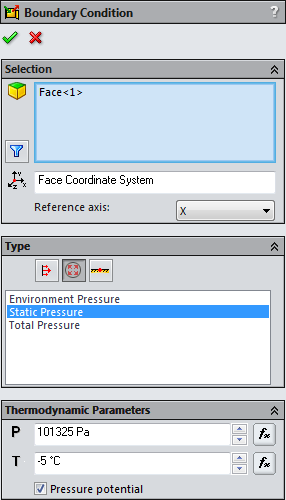

And I’ll insert another boundary condition on the inner face of the outlet lid

and define a Static Pressure as shown below.

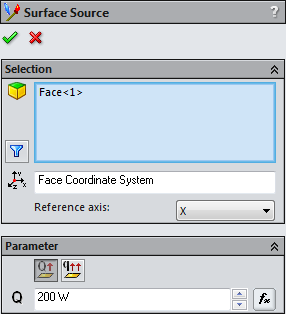

A surface source can be used to generate heat at the top of the plate. From

the Flow Simulation menu, I’ll select Insert, Surface Source.

I’ll select the top surface of the plate and enter a

Heat Generation Rate of 200 W.

The last thing to do before running the project is to define the goals. I’ll

right-click Goals, select Insert Global Goals, and select the

Max checkboxes for the Temperature (Fluid) and

Temperature (Solid).

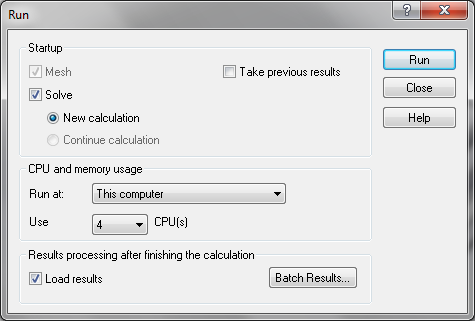

And that’s it. The project is ready to run. I’ll right-click the project name,

select Run, ensure that the checkbox for Solve is selected, and

click the Run button. This initial setup is a good start for this

problem, but it’s of course a great idea to refine the setup after running the

analysis and taking a look at the results.

Once the analysis is complete, there are many ways to investigate the results.

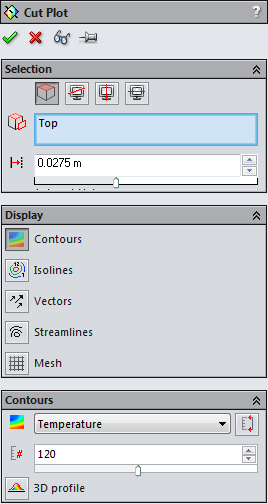

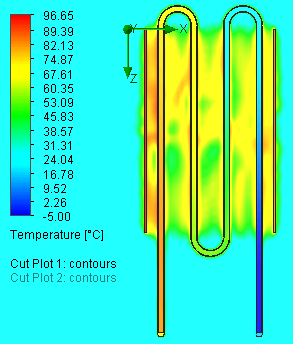

As an example, I’ll create a cut plot to view the temperature of the coolant

in the tube. I’ll right-click Cut Plots and select Insert. I’ll

set my plot halfway through the tube, 0.0275 m above the

Top Plane, and choose to show Temperature Contours.

The plot shows that the coolant rises from its initial temperature of -5 °C to

a maximum of about 80 °C by the end of the tube.

Better performance, especially at the left half of the cold plate, could

likely be achieved by reducing the temperature increase of the coolant, so

increasing the flow rate through the tube might be a good idea.

SOLIDWORKS Flow Simulation allows for changes to the design and analysis to be

cycled through at the same time and it shouldn’t be too long before an

improved cold plate is nailed down.

I hope you found this conjugate heat transfer example useful. If you have any

questions, please leave a comment and let us know.