pattern available for setting up patterned components along an open or

closed path. This is perfect if you want to dynamically simulate roller

chains, cable carriers, and power transmission systems.

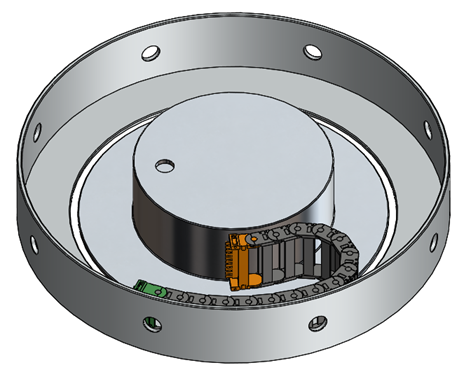

Energy Chain with Rotary Motion

The previous example would work great with some type of gantry with linear

motion. In this case, what if the motion is more circular or rotational than

linear?

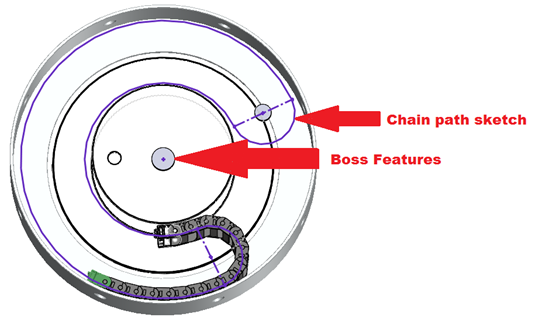

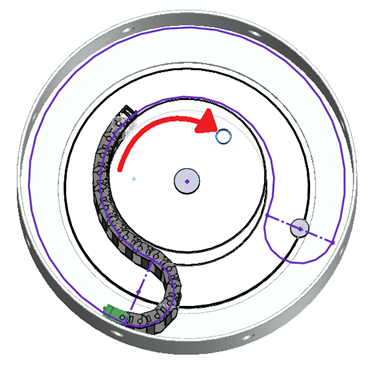

Well, it’s all in the sketch path that drives the Chain Component Pattern. You

aren’t limited to sketches only consisting of lines and arcs for the chain

path. You’ll notice that this case requires 3 arcs in the path: one that

defines the outer diameter (or the outer ring), one that defines the inner

diameter (or the hub), and a small arc that represents the bend or return

between the two.

Now in order for this to behave properly, the “dummy” component that contains

the chain path sketch must be properly constrained in the assembly. For the

correct rotary motion, the component must be concentric to the ring and hub

components and, in this case, constrained to the hub so that when the inner

hub is dragged (rotated), the chain path moves with it and therefore drives

the Chain Component Pattern to move with it. (See below.) Extra features such

as bosses and/or reference geometry may be needed in the chain path sketch

part to allow you to mate things together as desired.

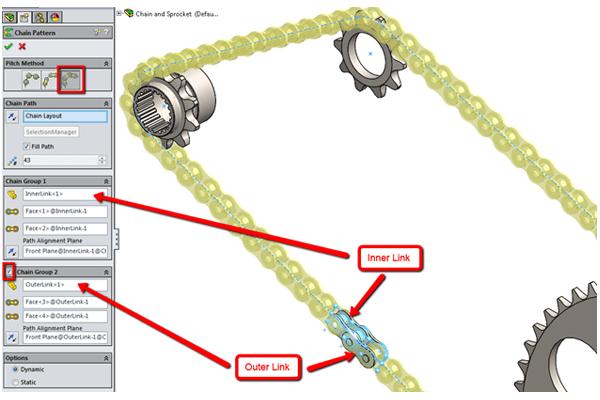

Closed Loop Chain

Now let’s take a look at a perfect example of a closed loop chain. This one

has another interesting twist as unlike the energy chain, which uses a single

type of link, a bicycle chain has two types of alternating links.

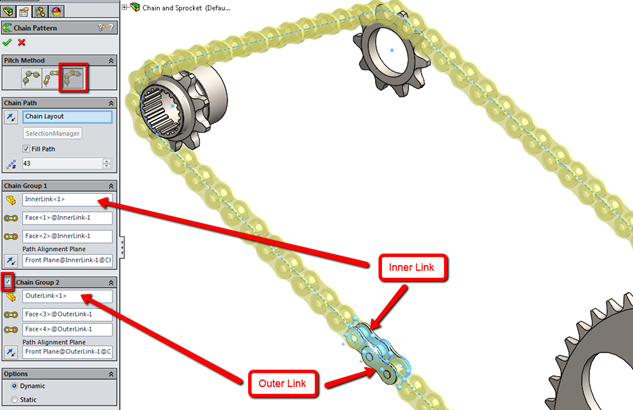

When we set up this feature, we’ll need to pattern both the Inner and Outer

Links that alternate to make the chain. We’ll use the “Chain Group 2” option

and selections to accomplish this.

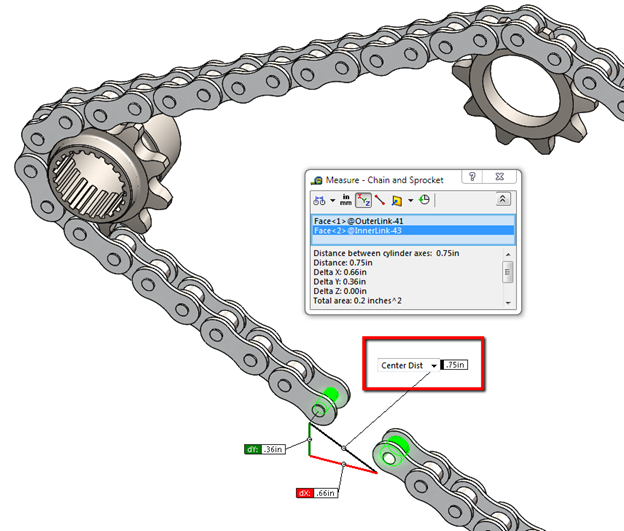

Something else to consider here is that in reality, the final link in the

chain would be attached to the first link in order for it to be a closed loop.

However, we cannot create the mate to accomplish that in SOLIDWORKS. So, how

do we make sure the total length of our path is correct so that the final link

does indeed meet the first one?

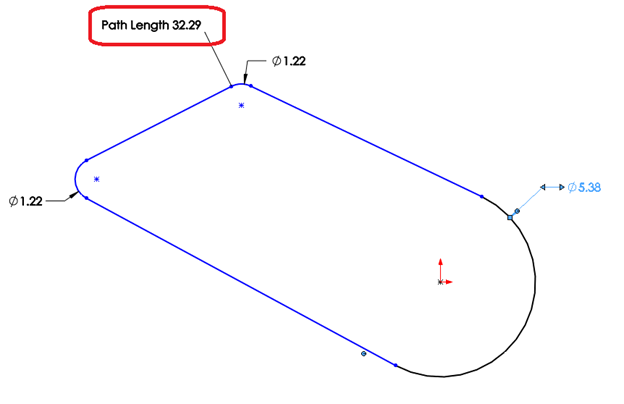

The trick here is to determine the total number of links you want and use the

“Fill Path” option. Once this is done, you can measure the remaining gap

between the first and last component. Using the Path Length Dimension, adjust

the sketch path by that amount to close the gap.

In-Context Chain Path Sketch

There are applications where the movement of the chain is dependent on the

position of other components in the assembly to which the chain is attached.

This is easily done by creating an in-context sketch constrained to the moving

component, in the chain sub-assembly.

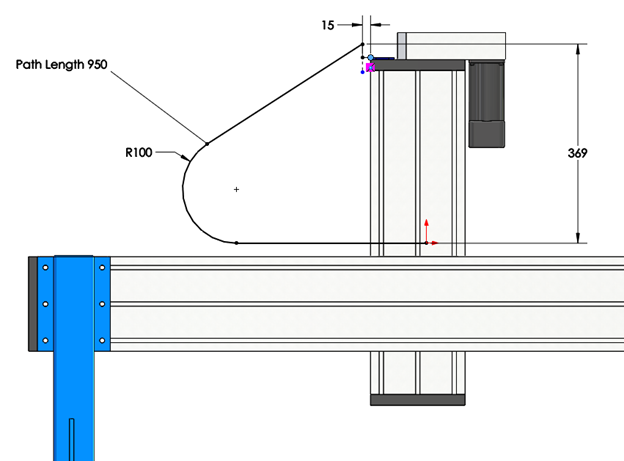

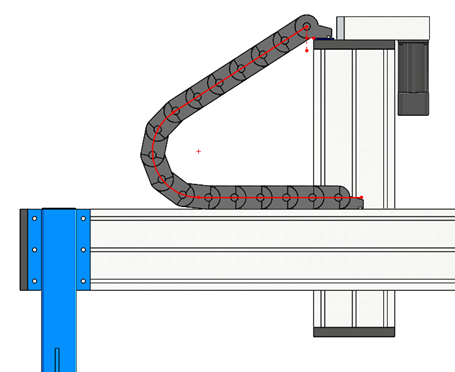

In this example we have a gantry system where the chain path sketch is defined

in the context of the assembly to the vertical head component. Notice the

angle of the path is not specified; it is dependent on the position of the

head component.

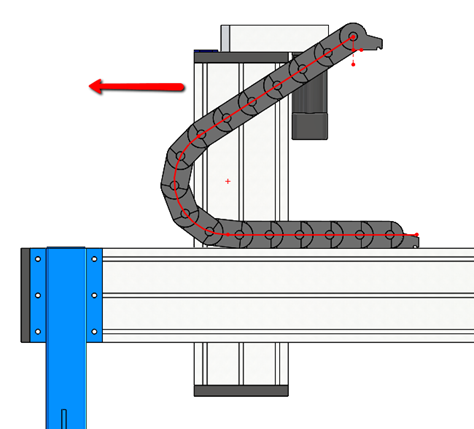

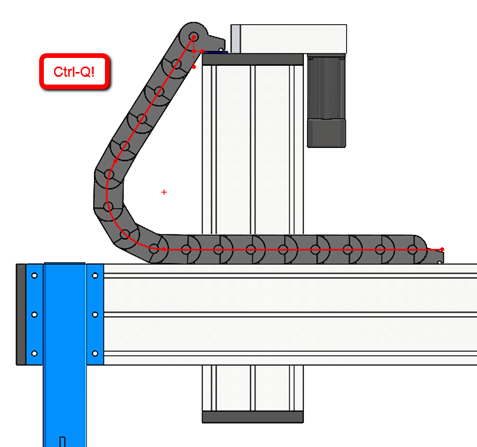

Now, there is one difference in the behavior of the chain movement when using

in-context referencing for driving the chain path. When the component (the

head) is moved, the chain motion will not be real-time. The top level assembly

MUST be rebuilt so that the chain path sketch is solved for the new location

of the component, which then allows the chain component pattern to be solved.

This is still very useful for positioning information in your design and

drawings.

In part 3 of this series, we’ll take a look at special considerations

regarding optimum behavior and performance when using the Chain Component

Pattern in

SOLIDWORKS 2015.