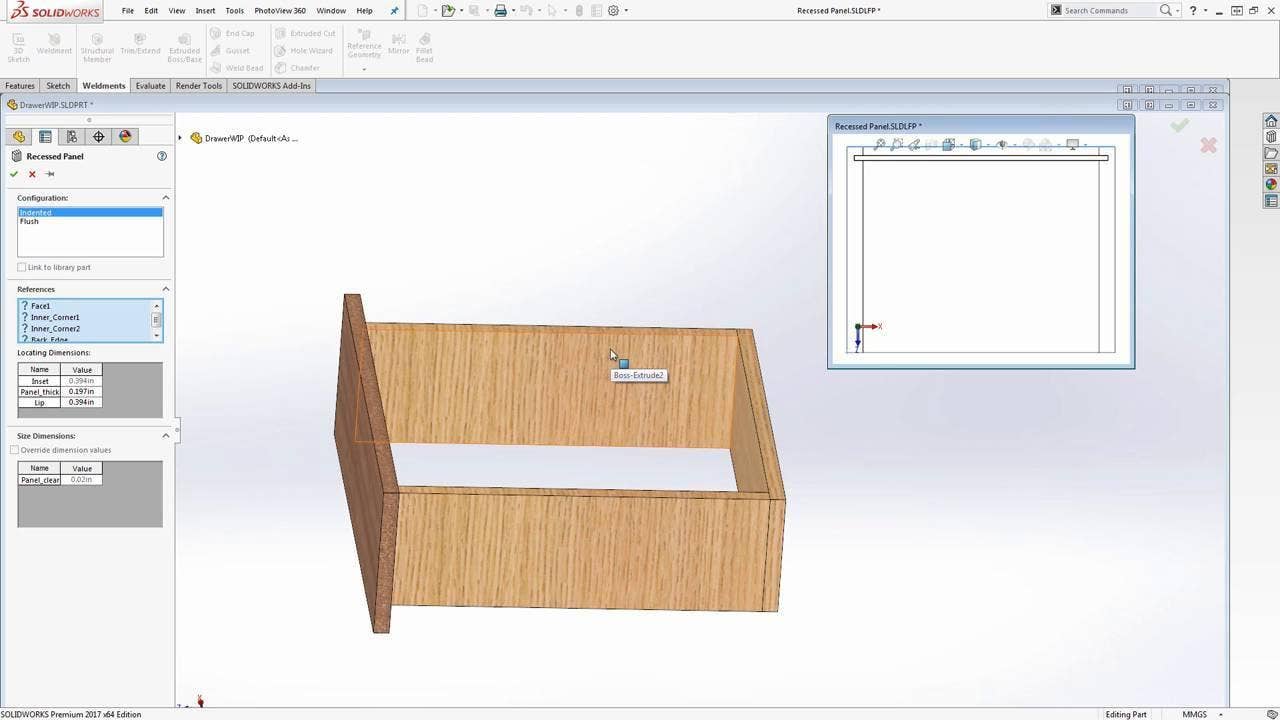

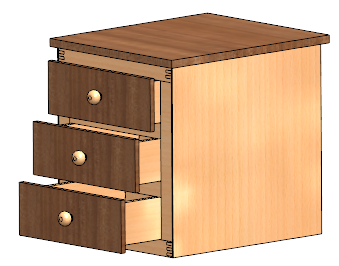

The previous article discussed capabilities of SOLIDWORKS useful for the

woodworking industry on an example of a set of frameless cabinets. This

article and companion video will discuss the design of framed cabinetry in

SOLIDWORKS as well as some additional modeling details, on an example of a

simple set of drawers:

|

Worth noting is that the motion of drawers, doors or nearly any hinged or

sliding mechanism can be simulated in a SOLIDWORKS assembly to check for a

range of motion and interferences.

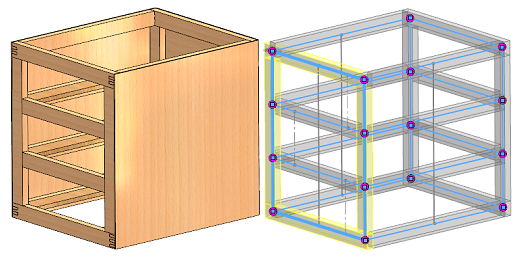

Focusing on the cabinet itself, we can see that it is made up of 1x2s. An easy

way to represent these types of framed structures in SOLIDWORKS is to use the

Weldments “Structural Member” tool.

The structural member tool was originally intended for large steel framed

structures but has also found popularity in other applications such as

woodworking, as users can easily define their own profiles for stock material

sizes. This tool allows assigning of the desired profile to a single-line

outline sketch and performs automatic trimming of the various members against

each other.

|

Also of importance is the automatic creation and tracking of a cut list. Any

members created with the Structural Member tool automatically have their cut

length tracked and identical cut items grouped together, allowing the user to

quickly generate a cut list for shop drawings.

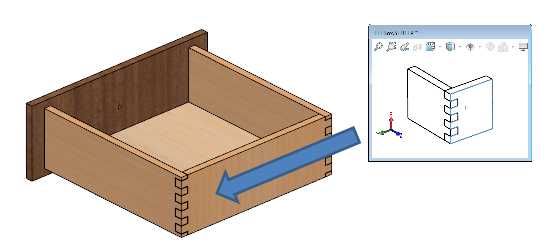

Focusing down on the level of an individual drawer, repetitive design tasks

such as joinery features can be automated through the creation of “Design

Library” features such as Smart Features and Smart Components. These allow the

user to define SOLIDWORKS features on a dummy part, which then allows dragging

and dropping the desired features onto the current design. A preview window

guides the user through selecting any references necessary to associate the

feature.

|

Smart Components establish a similar functionality at the assembly level. One

application of Smart Components would be to allow a user to place a piece of

hardware such as a hinge, and automatically propagate the hole pattern

necessary for the hardware, as well as insert any required fasteners.

For more information, check out our

YouTube channel

or contact us at

Hawk Ridge Systems

today. Thanks for reading!