Are your designers and engineers surrounded by whirlwind of activity caused by the need to differentiate your product all the while trying to beat competitors to market? There is a lot of stress that goes along with shortened cycles and high stakes which is why designers and engineers are finding themselves in complex environments; attempting to predict product behavior and meet deadlines. To add to this stress, many find themselves in the unenviable position of waiting for physical prototypes and relying on hand calculations only to find they are met with costly setbacks and rework, putting their design right back at the starting line.

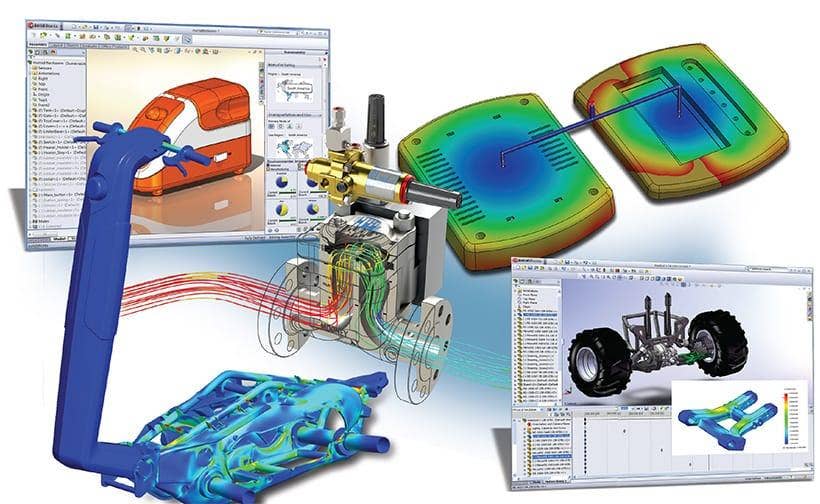

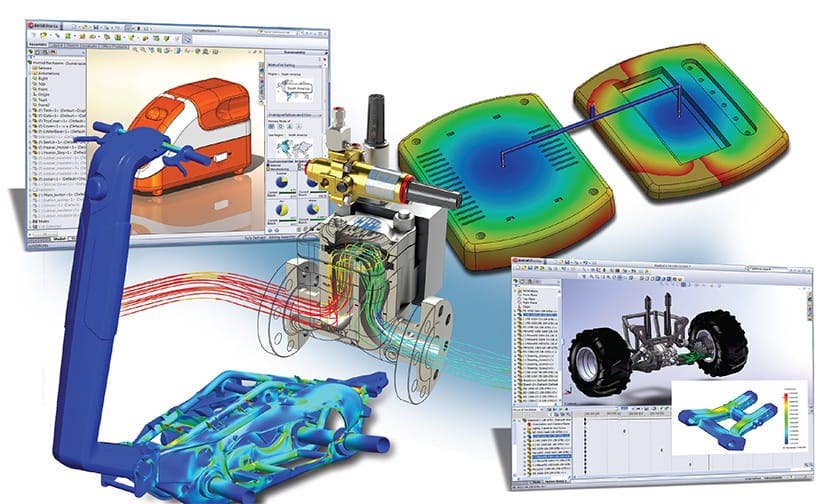

What if I told you there is a way around all of this? Aberdeen Research recently conducted a study, “Virtual Prototyping vs. Traditional Product Development Methods” that shows how best-in-class companies are using virtual prototyping during the design process so they can understand how their designs will work in the real world. That’s right – companies can test early and identify problems BEFORE the late stages of the product development process. They are saving themselves time, money and even avoiding a few extra gray hairs. Thanks to Aberdeen, we can share with you a very helpful guide of “Seven Reasons You Should Provide Virtual Prototyping to Your Designers”.

Your 7 Reasons You Should Provide Virtual Prototyping to Your Designers:

1. Complexity keeps growing and manual calculations cannot keep pace.

Complexity within products and their operating environments are the top two challenges identified by developers. Hand calculations are only effective on the most basic of products.

2. Design resources are limited; virtual prototyping greatly improves engineering efficiency.

67% of Best-in-Class companies rely on virtual prototyping for validation and verification.

3. A design can only be fully optimized in a virtual environment.

Virtual prototyping software makes it possible to evaluate the performance of multiple variables at a rapid pace. Hand calculations and physical prototypes only provide a singular answer.

4. Virtual prototyping greatly reduces the dependency on physical prototypes.

Since designs can be tested virtually, users of virtual simulation saw a 10% decrease in complete porotypes.

5. Products are designed correctly the first time.

Virtual prototyping allows for the entire system to be analyzed, which means more accurate results. This is back up by a 6% decrease in ECOs for users of virtual prototyping software.

6. The storage and management of manual calculations bring unique challenges.

Calculations done through in-house Excel files are hard to collaborate through and introduce risk if a designer is working on an outdated version.

7. It all comes back to costs.

Optimized designs, less rework, and fewer physical prototypes all combine to greatly reduced costs. 71% of Best-in-Class users, who favor virtual prototyping, meet their product cost target, versus only 63% of all others.

In the FULL REPORT, Aberdeen summarized the experiences of over 550 respondents from companies who have turned to virtual simulation and found that:

- Best-in-Class companies are 53% more likely than their peers to conduct their simulations in this virtual environment.

- Virtual Simulation users saw a 16% decrease in overall development time.

- Virtual Simulation users saw a 13% decrease in overall product cost for new products.

- Highest performing companies are 10% more likely to meet product revenue targets

- Best-in-Class companies are 17% more likely to meet product launch targets.

- For the product targets used to define Best-in-Class companies, virtual simulation easily outperformed hand calculations and physical prototypes.

- Virtual Simulations users reduced the number of physical prototypes by 48%.

Are you ready to put an end to bad product behavior? Contact us today for a FREE SIMULATION DEMO.