Predator PDM

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

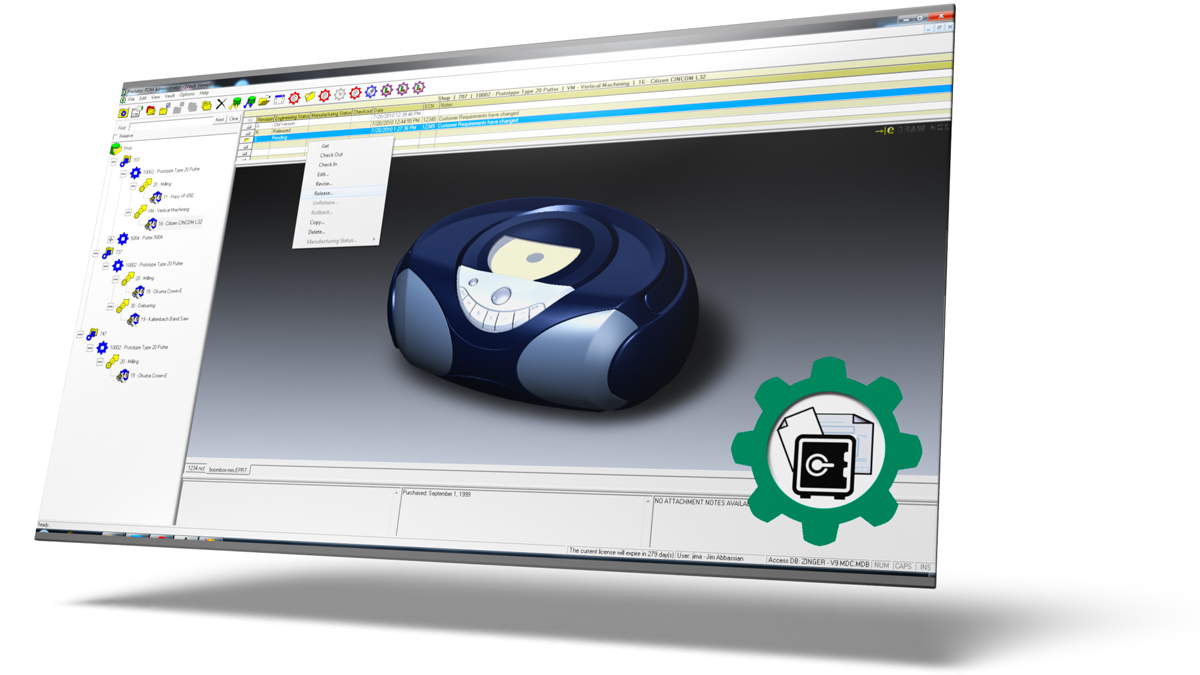

Organize Your Shop Floor With Predator Data Management

After implementing Predator PDM, you will have everything you need, from CNC programs, to process sheets, setup sheets, inspection sheets, and more, in a single accessible location for everyone on your shop floor. The software promotes best practice workflows and ensures you’re making the right part every time with all your documentation in one place.

From startups to global OEMs, Predator PDM will bring order to the smallest shop or can be scaled to connect multiple plants. Using industry-standard technology, Predator PDM reduces downtime, promotes efficiency, and supports audit trails and ISO implementation. Available in both Standard and Enterprise versions, it is compatible with Predator DNC, MDC, Editor, Tracker, and more.

Key Features & Benefits

Best Practice Workflows

Predator PDM includes best practice workflow wizards for release, unrelease, revise, rollback, check-in and check-out. These wizards honor permissions and include ISO 9000 style history.

Open API and Database Architecture

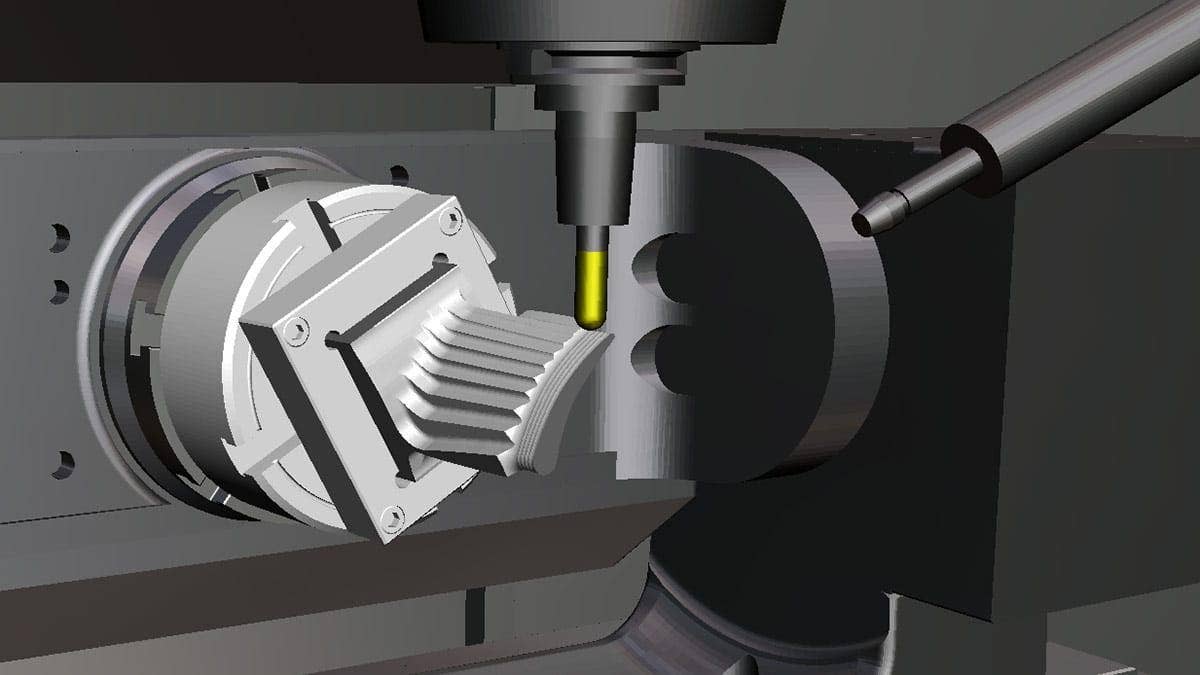

Predator DNC Integration

Download released CNC programs to their machines using Predator DNC with a single click.

Predator CNC Editor Integration

Compare and backplot CNC programs with the Predator CNC Editor with a single click.

Predator MDC Integration

Initiate manual data collection events such as job start, part start, operation start, setup start – and many others – with Predator MDC with a single click.

Predator Tracker Integration

View tools, cutters, inserts and gages with Predator Tracker with a single click.

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training, and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions, and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Manufacturing Resources

Are Your CAM Tools Working Together? They Should Be.

Watch Webinar

Introduction to SOLIDWORKS CAM

Watch Video

Alien Machine Worx Success With SOLIDWORKS

Watch Video

3 Strategies to Master for Future Manufacturing Success

Download GuideFrequently Asked Questions

Predator PDM is an ideal tool for bringing order and efficiency to your manufacturing process, while reducing or eliminating errors that stem from poor revision control and failed communication between departments.

Yes, Predator PDM integrates seamlessly with every major Predator package.

Predator PDM uses many common out-of-the box and industry standard technologies to make it easier to implement and learn. If your people can navigate Microsoft Windows File Explorer, they will feel right at home with Predator PDM.

Services & Customer Benefits

Technical Support

Our global support team efficiently addresses your needs. We’re here to minimize downtime and costs when your machines encounter issues. If we supply a post processor, expect ongoing support and updates throughout your contract.

Unmatched Training

Our Certified CAM trainers draw from extensive software and real-world machining experience for your productivity. Choose from various training options, including self-paced, instructor-led, and private, tailored to your needs and learning style.

Professional Services

We offer comprehensive CAM and CNC machining software services, including swift implementation, free or customized post processors for seamless software-machine integration, and personalized consulting for ongoing productivity.