Predator DNC

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Network Your Machines, PLCs, 3D Printers, and Manage Your Files.

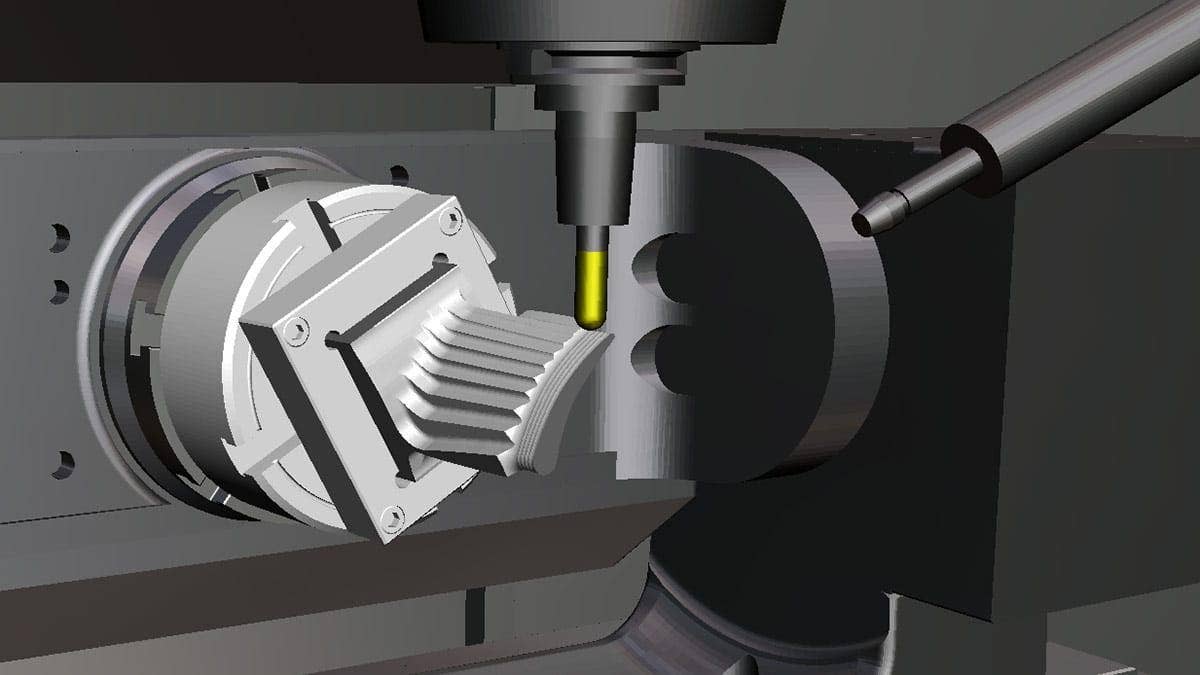

Predator DNC helps you control files being sent to and from your CNC machines, keeping you ahead of part revisions for your machines to stop running the wrong revisions. Programs can be transferred either automatically or manually depending on your criteria. You can transfer ISO, conversational, and binary formats, machine variables, tool offsets, work offsets, parameters – and more – with over 50 communication protocols. Predator DNC uses wired, multiport hubs, wireless, or ethernet for communications, and supports RFID chips, BTRs, and bar code readers.

Optional Touch HMI allows you to communicate with machines from a shop floor PC or handheld tablet for instant visual confirmation of processes, with operator-friendly, customizable screens. You can also upgrade to PDM for secure revision control, or MDC for comprehensive data collection.

Key Features

|

Features

|

Predator DNC

|

|---|---|

|

Maximum Number of Machine or Ports

|

The maximum number of remote commands and machines per PC or server is 4,096.

|

|

Wired and Wireless Hardware Support

|

Connections can be wired or wireless, and are able to be mixed.

|

|

Ethernet Support

|

Predator can connect via Ethernet if the machine is so equipped

|

|

Automatic Saming of Received Programs

|

With a remote request, Predator can be setup to automatically name your programs.

|

|

CNC Editor

|

Predator’s fully functional CNC editor is included.

|

|

Basic and Advanced Serial Machines Communications

|

Any CNC machine with serial communications can be addressed.

|

|

Drip-Feeding

|

Predator DNC can drip-feed large programs to machines.

|

|

Restart Programs

|

The software supports mid-program restarts after tool breaks during drip-feeds. Restarts can occur remotely or at the PC.

|

|

File Viewers

|

Predator supports most types of file viewer.

|

|

Touch HMI

|

This optional add-on can be used to customize operator screens on tablets and floor PCs for communication.

|

|

Run Script Files

|

Optionally, VB script files can be supported and executed to do various functions.

|

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training, and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions, and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Manufacturing Resources

Are Your CAM Tools Working Together? They Should Be.

Watch Webinar

Introduction to SOLIDWORKS CAM

Watch Video

Alien Machine Worx Success With SOLIDWORKS

Watch Video

3 Strategies to Master for Future Manufacturing Success

Download GuideFrequently Asked Questions

Yes, Predator’s DNC system can mix with any number and type of hardware.

Predator BTRs will act as an interface between the tape reader and machine to allow you to transfer files to them. This also increases the memory of the machine.

Yes, Predator software can send and receive in Mazatrol format.

Yes, Predator DNC can be setup to automatically send files from your work orders.

Services & Customer Benefits

Technical Support

Our global support team efficiently addresses your needs. We’re here to minimize downtime and costs when your machines encounter issues. If we supply a post processor, expect ongoing support and updates throughout your contract.

Unmatched Training

Our Certified CAM trainers draw from extensive software and real-world machining experience for your productivity. Choose from various training options, including self-paced, instructor-led, and private, tailored to your needs and learning style.

Professional Services

We offer comprehensive CAM and CNC machining software services, including swift implementation, free or customized post processors for seamless software-machine integration, and personalized consulting for ongoing productivity.