Markforged Inspection Software

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Quality Assurance Software for the Markforged Industrial Series

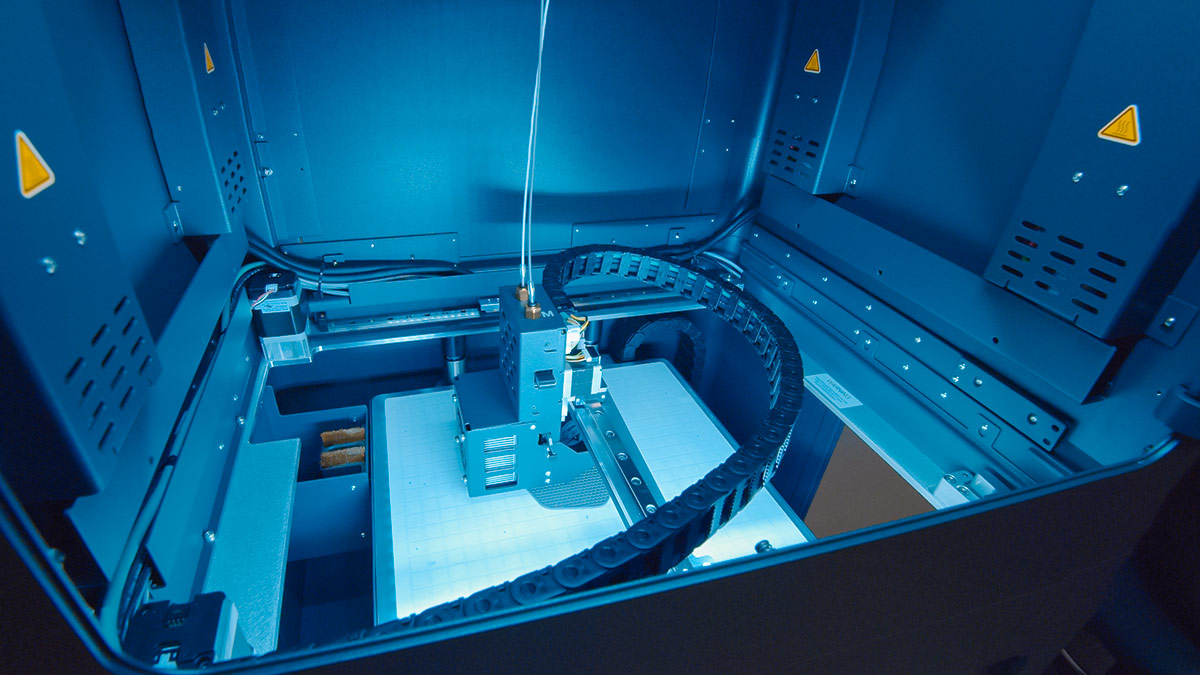

Seamlessly integrated into the production process, Inspection enables laser scanning while parts print, streamlining part design, production, and quality control. Included in the Digital Forge Complete Advanced Plan, Inspection offers rapid quality control via automated scanning and inspection as parts print, allowing immediate usage.

Compatible with X3™, X5™, and X7™ Industrial printers, Inspection ensures precise, compliant parts are delivered quickly, eliminating the need for expensive and time-consuming post-print inspections. With detailed process control data, users can track the printing process, including who printed the parts when they were printed, and which printer/software version was used, enhancing transparency and accountability.

Key Features & Benefits

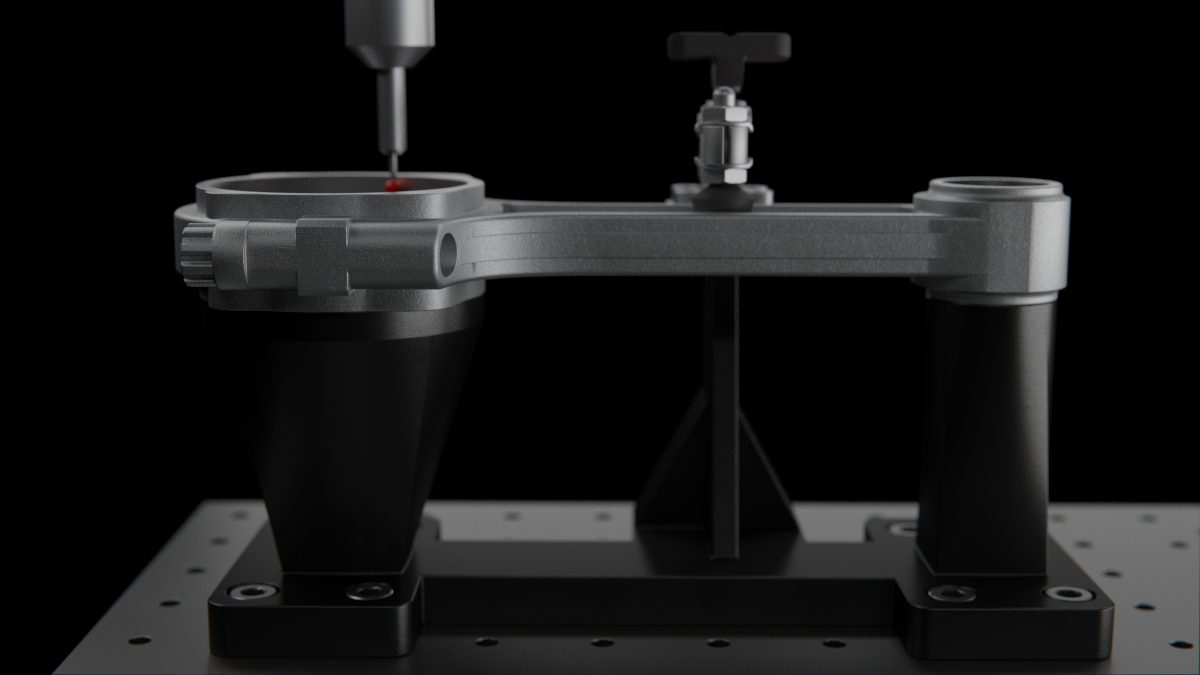

Point Cloud Accuracy Verification

In-Depth Part Inspection

Scan Reports

Scan History

Enhanced Part Performance

Reduced Material Waste

Revolutionizing Dragsters With Markforged

In the high-speed, high-stakes world of jet engine drag racing, manufacturing quality parts is a matter of life and death. Just ask Josette Roach, one of only five female jet dragster drivers in the entire world.

Josette Roach and Brian Tocci of Larsen Motorsports saw the need to create a custom steering wheel for Josette’s jet car that would fit her hands exactly. Enter Markforged, and our Simulation software, which allowed the team at Larsen to build this part with top-end accuracy.

Markforged Resources

See It Firsthand: The New Markforged FX20

Watch Live Stream

An Overview of Markforged Materials

Watch Video

Choosing Your Markforged 3D Printer

Download Guide

Launching Careers With Markforged

Watch VideoFrequently Asked Questions

Not at this time. Inspection is currently a verification tool that will provide an accuracy report.

Inspection is designed for Adaptive Manufacturing which will use AI to improve printer accuracy for specific part geometries based on scan data.

Inspection can only be enabled on Industrial machines after the system has been calibrated using an external calibration board artifact. Reach out to Hawk Ridge Systems to order a calibration board and sign up for a subscription.

After your machine has been calibrated, you are able to turn on Inspection for individual part files within Eiger. As the part is being printed, the machine will scan layer by layer, creating a point cloud that will be compared to your original STL data. Lastly, you will receive a notification once your part and scan report are complete and ready for download.

Yes. Inspection allows for closer inspection of scan data, filtering based on accuracy thresholds, and comparative analysis from different surfaces and planes.

Inspection is only available on the Markforged industrial line of printers.

Services & Customer Benefits

Technical Support

Unmatched Training

Hawk Ridge offers complete self-paced training programs for the Markforged line of 3D printers. Learn printer operations, how-tos, and best practices when it’s convenient for you.