Hexagon Absolute Arm

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

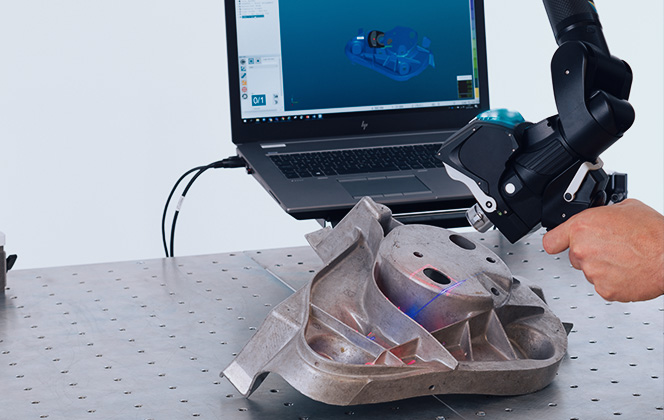

Portable Scanning and Probing for All Manufacturing Needs

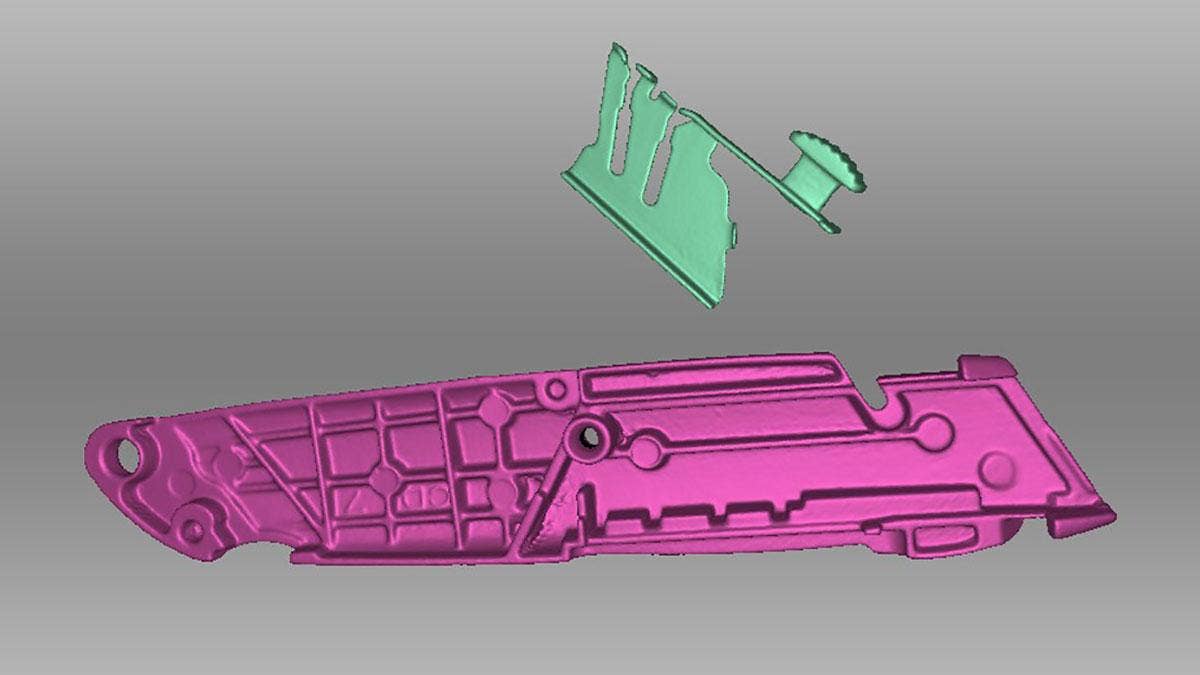

By combining scanning and probing into a single device, the Hexagon Absolute Arm (formerly known as the Romer Arm) offers versatile measurements for any part, capturing data in various ways to suit different objectives.

Innovative RFID technology allows users to switch between probes and scanners effortlessly, without the need for new calibration.

Key Features & Benefits

Total movement for an arm

Swap settings on the device

Absolute portability

Hot-swap accessories

Measure with confidence

Technical Specifications

|

Features

|

83 series

|

85 series

|

87 series

|

|---|---|---|---|

|

Accuracy

|

0.048 - 0.158 mm

|

0.031 - 0.113 mm

|

0.029 - 0.104 mm

|

|

Probing Accuracy

|

0.023 - 0.078 mm

|

0.012 - 0.048 mm

|

0.011 - 0.044 mm

|

|

Max Reach

|

2.98 - 4.98 m

|

2.98 - 4.98 m

|

2.98 - 4.98 m

|

Exceptional Solutions, Even Better Support

Creating the best products requires the best solutions, training, and support. With a little insight into your product development process, our team of pros can point you to any tools you need (and nothing you don’t).

But it doesn’t end there. We’ll stay with you every step of the way, helping solve complex design issues, 3D printing application questions, and so much more. No matter where you’re at, both in your process and geographically, we’re here.

Services & Customer Benefits

Technical Support

Our scanning support specialists are 100% dedicated to our 3D scanning applications, have passed rigorous testing standards, and have extensive experience using our scanning products in the real world.

Unmatched Training

Every company is different, and when it comes to training for 3D scanning, one size doesn’t fit all. Hawk Ridge Systems can tailor a training plan to focus on the needs of your application.

Professional Services

Frequently Asked Questions

3D Scanning Resources

Preserving History With 3D Scanners

Download Guide

3D Scan-To-CAD: How to Model Almost Anything

Watch Webinar

The Artec Ray 3D Scanner in Extreme Environments

Read Article